Bactericidal composition

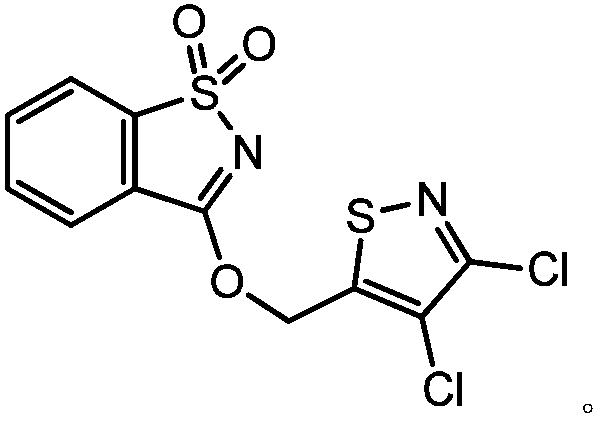

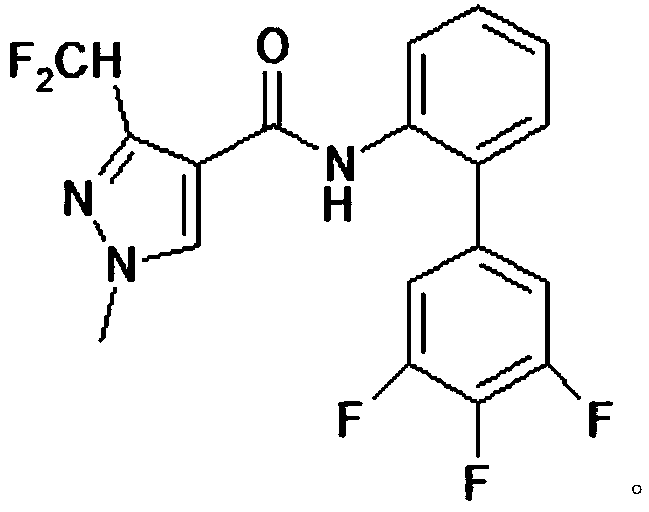

A composition, the technology of flufenapyramide, applied in the field of pesticides, can solve the problems of pesticide abuse, severe environmental pressure, and increased use of pesticides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

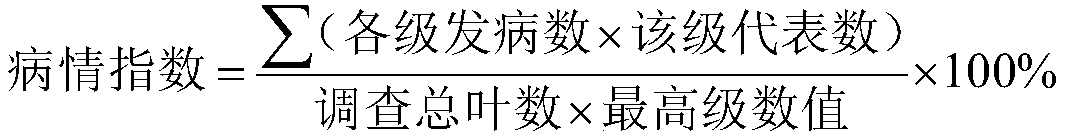

Method used

Image

Examples

preparation example 110

[0114] Preparation Example 1 Preparation of 10% Dichlobentiazox·flufenapyramide EC

[0115] Add 7.5g of Dichlobentiazox and 2.5g of flufenapyroxad to a mixed solvent of 30g of cyclohexanone (Aladdin’s reagent) and 50g of aromatics 200# (Yangzhou Tianda Chemical Industry Co., Ltd.), and use an ultrasonic cleaner to vibrate for 5 minutes until the original drug is completely dissolve. Then emulsifier 601# (triphenylethylphenol and ethylene oxide adduct, Xingtai City Yancheng Chemical Auxiliary Co., Ltd.) 6g, emulsifier BY-110 (castor oil polyoxyethylene ether, Xingtai City Yancheng Chemical Auxiliary Co., Ltd.) 4g was added to the above solution and stirred evenly to prepare an emulsifiable concentrate with a mass content of 10% active ingredient.

preparation example 225

[0116] Preparation Example 2 Preparation of 25% Dichlobentiazox·flufenapyramide aqueous emulsion

[0117] ①Oil phase preparation

[0118] Add 20g of Dichlobentiazox original drug and 5g of flufenapyramide into a mixed solvent of 20g of aromatic solvent 200# (Yangzhou Tianda Chemical Industry) and 10g of HMK-150 (environmentally friendly polyalcohol ether solvent, Beijing Hammock), and then emulsify Agent BY-110 (castor oil polyoxyethylene ether, Xingtai Yancheng Chemical Auxiliary Co., Ltd.) 4g, Nongru 1601# (tristyrylphenol polyoxyethylene polyoxypropylene ether, Xingtai Yancheng Chemical Auxiliary Co., Ltd. Company) 2g was added and stirred slowly until completely dissolved.

[0119] ②Water phase preparation

[0120] 4 g of ethylene glycol (Aladdin's reagent), 0.2 g of an antifoaming agent (AFE-1520, Dow Corning) and 34.8 g of water were stirred evenly.

[0121] ③Water-emulsion formulation of the composition

[0122] Slowly add the oil phase to the water phase, and conti...

preparation example 330

[0123] Preparation Example 3 Preparation of 30% Dichlobentiazox·flufenapyramide suspension

[0124] ① Preparation of pre-crushed slurry

[0125] Dichlobentiazox technical 15g, flufenapyramide 15g, dispersant Agrilan 788 (anion-modified carboxylic acid copolymer, AkzoNobel) 2g, TERSPERSE 2500 (comb structure polymer compound, Huntsman) 3g, wetting agent GY- Mix 2g of WS10 (polyether, Beijing Guangyuan Yinong), 0.4g of water-based defoamer AFE-1520 (Dow Corning), 0.5g of magnesium aluminum silicate (Aladdin reagent) and 42.6g of deionized water, and then disperse with high speed Machine (IKA, Germany) sheared at high speed for 10 minutes to prepare pulverized slurry.

[0126] ②Sand grinding slurry preparation

[0127] All the pre-crushed slurry obtained in step ① is transferred to a sand mill (Jiangsu Changzhou Zhuoying Drying Co., Ltd.) The glass beads were wet crushed for 2 hours until the particle size of the slurry was about 3um, and a sand-milled uniform slurry was obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com