Membrane casting agent and preparation method thereof

A casting film, uniform technology, applied in the direction of chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of decreased membrane flux and separation efficiency, easy to cause organic pollution, large damage to membrane strength, etc., to improve hydrophilicity , enhance the degree of bonding, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

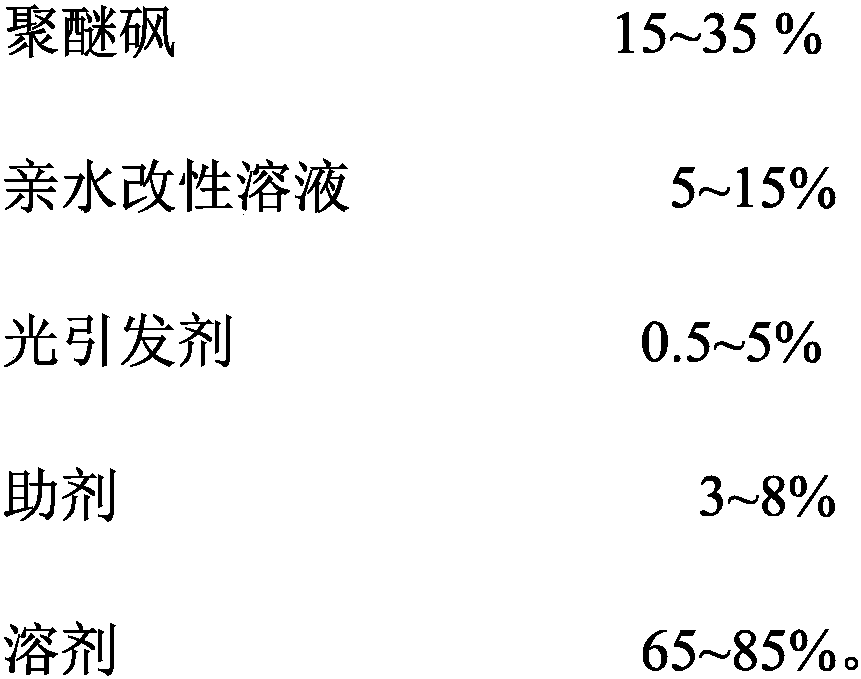

Method used

Image

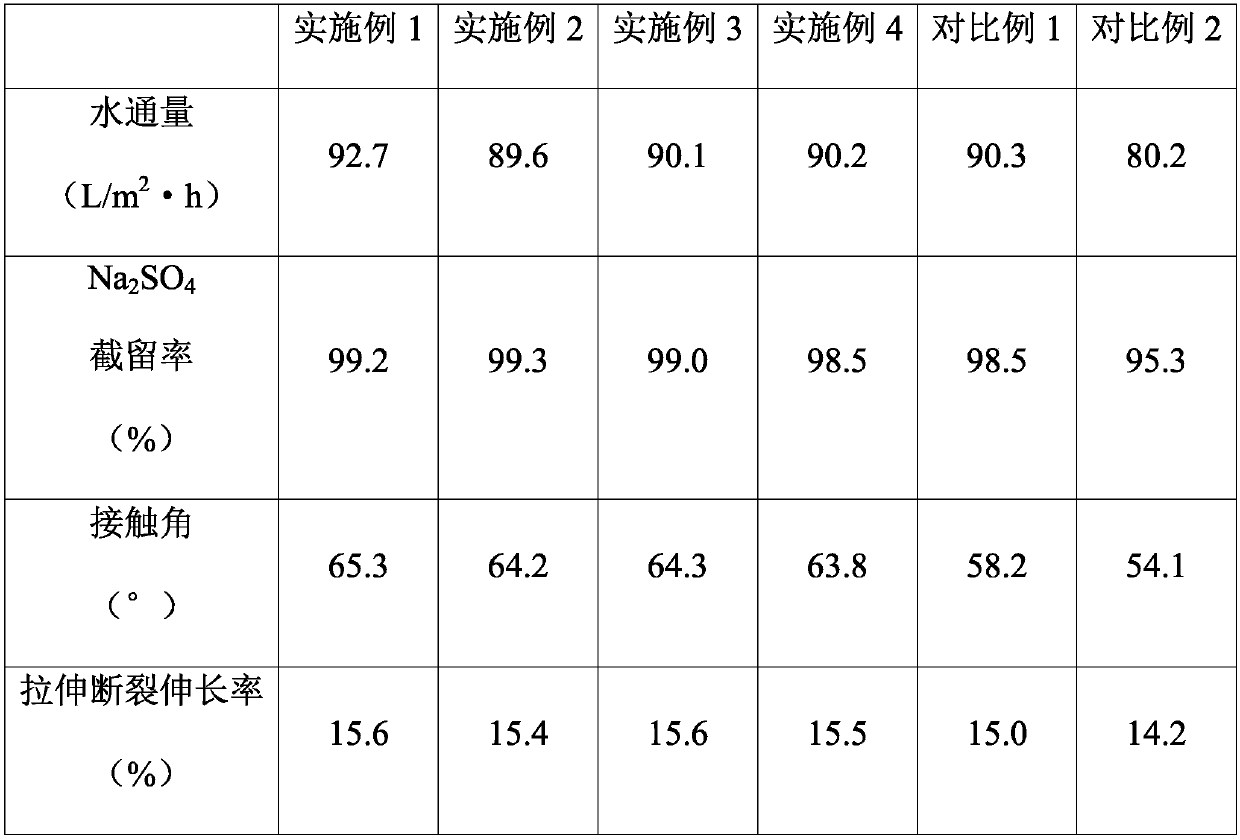

Examples

Embodiment 1

[0024] Mix and stir 10g cinnamic acid and 10g polyethyleneimine, stir for 1h to obtain a hydrophilic modification solution, mix 15g polyethersulfone and 5g hydrophilic modification solution respectively, heat to 70°C, stir for 1h to obtain a solute solution, and then Add 0.5g of photoinitiator 910, 1g of trimethylolpropane trimethacrylate, 1g of polyvinylpyrrolidone, 1g of citric acid and 0.2g of ethylene glycol, mix and heat to 80°C, stir for 1h to obtain a mixed solution, mix The solution was decompressed and left to defoam, the decompression vacuum degree was 0.1Mpa, and the decompression was 30min. After the decompression was completed, the mixed solution was irradiated under an ultraviolet light for 2min to obtain a film-casting agent, which was used to prepare an ultrafiltration membrane. And the ultrafiltration membrane performance test.

Embodiment 2

[0026] Mix and stir 10g cinnamic acid and 50g polyethyleneimine, stir for 2 hours to obtain a hydrophilic modification solution, mix 35g polyethersulfone and 15g hydrophilic modification solution respectively, heat to 80°C, stir for 2 hours to obtain a solute solution, and then Add 5g of photoinitiator 1173, 1g of pentaerythritol tetraacrylate, 1g of polyvinylpyrrolidone, 1g of salicylic acid and 1g of polyethylene glycol, mix and heat to 80°C, and stir for 2 hours to obtain a mixed solution, which is left to stand under reduced pressure to remove Bubble, decompression vacuum degree is 0.1Mpa, decompression 60min, after decompression is completed, the mixed solution is placed in the ultraviolet lamp irradiation 5min, obtains the film-casting agent, utilizes the film-casting agent to prepare ultrafiltration membrane, and ultrafiltration membrane is carried out Performance testing.

Embodiment 3

[0028] Mix and stir 10g cinnamic acid and 100g polyethyleneimine, stir for 1.5h to obtain a hydrophilic modification solution, mix 25g polyethersulfone and 10g hydrophilic modification solution respectively, heat to 70°C, and stir for 1.5h to obtain a solute solution , then add 3g of photoinitiator 184, 2g of ethylene glycol dimethacrylate, 2g of polyvinylpyrrolidone, 2g of acetic acid and 0.1g of glycerin, mix and heat to 80°C, stir for 1.5h to obtain a mixed solution, and depressurize the mixed solution Leave standstill to defoam, the decompression vacuum degree is 0.1Mpa, decompression 40min, decompression is completed, the mixed solution is placed in ultraviolet light and irradiates 4min, obtains the film-casting agent, utilizes the film-casting agent to prepare ultrafiltration membrane, and to ultrafiltration Filter performance testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com