Degradable environment-friendly plastic film and its production process

A plastic film, environmental protection technology, applied in the field of degradable and environmentally friendly plastic film and its production process, can solve the problems of uneven hydrophobicity, poor dispersion of polylactic acid, uneven dispersion of hydrophobic agent, etc., to achieve uniform flame retardancy, high The effect of dispersion power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The specific preparation process of hydrophobic composite polylactic acid is as follows:

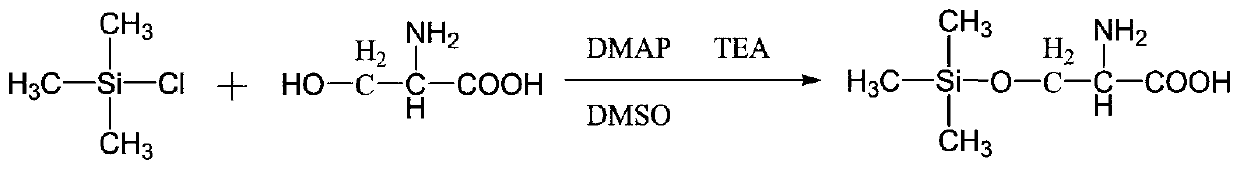

[0040] Step 1: Add 200g of serine to the dimethyl sulfoxide solution, then add 620mL of triethylamine and 76g of 4-dimethylaminopyridine to it, stir evenly, add 212g of trimethylchlorosilane to it, and stir at room temperature for 25- After 27 hours, a trimethylsilane ether compound solution was obtained, and the specific reaction structural formula was as follows, and the hydroxyl group in serine could be protected by adding trimethylchlorosilane;

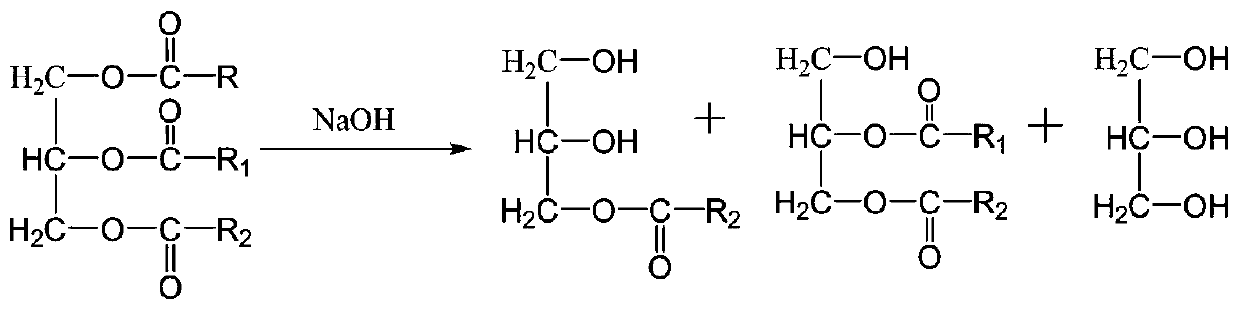

[0041] Step 2: Take 1 kg of vegetable oil and add it to the absolute ethanol solution, then add 31 g of sodium hydroxide solid to it, heat up to 75 ° C and stir for 2 hours, then use a separatory funnel to separate the obtained product, and take the upper layer solution, Obtain semi-saponified vegetable oil;

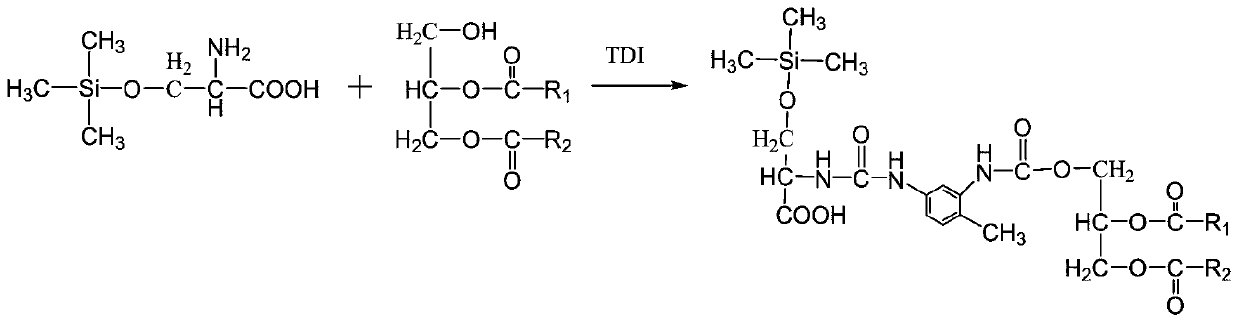

[0042] Step 3, add 108 g of the semi-saponified vegetable oil prepared in step 2 to 200 g of the trimethylsilyl ether compoun...

Embodiment 2

[0046] The specific preparation process of hydrophobic composite polylactic acid is as follows:

[0047] Step 1: Add 200g of serine to the dimethyl sulfoxide solution, then add 680mL of triethylamine and 78g of 4-dimethylaminopyridine to it, stir evenly, add 224g of trimethylchlorosilane to it, and stir at room temperature for 25- After 27 hours, a trimethylsilane ether compound solution was obtained, and the specific reaction structural formula was as follows, and the hydroxyl group in serine could be protected by adding trimethylchlorosilane;

[0048] Step 2: Take 1 kg of vegetable oil and add it to the absolute ethanol solution, then add 33 g of sodium hydroxide solid to it, heat up to 75 ° C and stir for 2 hours, then use a separatory funnel to separate the obtained product, and take the upper layer solution, Obtain semi-saponified vegetable oil;

[0049] Step 3: Add 114 g of the semi-saponified vegetable oil prepared in Step 2 to 200 g of the trimethylsilyl ether compoun...

Embodiment 3

[0053] The specific preparation process of the composite polylactic acid is as follows: 95g of serine and 81g of L-lactic acid are added to the reaction vessel, and 1.5L of 1,4-butanediol and 24g of stannous octoate are added to it at the same time, heated to 150°C, vacuumized, and then reacted at a constant temperature 10-12h, cooled to room temperature, filtered and washed to obtain complex polylactic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com