Method for preparing metal rhodium or rhodium alloy by electrodeposition or chemical deposition

A technology of chemical deposition method and electrodeposition method, applied in the field of alloy preparation, can solve the problems of poor plating solution stability and large plating porosity, and achieve the effects of stable plating solution, high plating solution stability and high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

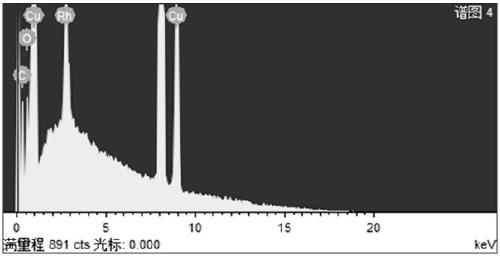

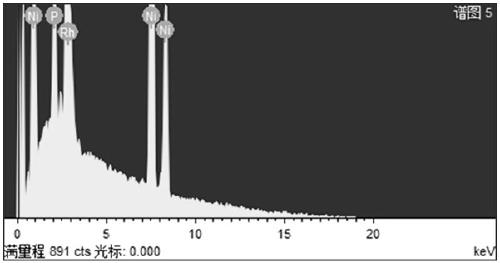

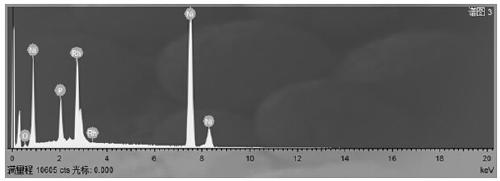

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: what this embodiment records is a kind of method for preparing metal rhodium or rhodium alloy by electrodeposition method, and the specific steps of described method are as follows:

[0025] (1) According to the method described in the patent CN105906668B, the rhodium salt is dissolved in the acidic solution, and the complexing agent is dissolved in the alkaline solution. After the two are mixed, the pH value of the solution is gradually increased under the condition of heating and stirring. Adjust to 5~12, obtain the complex compound solution of rhodium ion, be recorded as A solution;

[0026] (2) Prepare a complex solution of dissimilar metal ions with a dissimilar metal ion content of 2 mol / L, denoted as B solution;

[0027] (3) Mix A solution and B solution at a volume ratio of 1:0~10 (when B solution is 0, it is a plating solution for electrodepositing single metal rhodium), and adjust the pH value to 5.5~12 with ammonia water and acid solu...

specific Embodiment approach 2

[0029] Embodiment 2: Embodiment 1 describes a method for preparing metal rhodium or rhodium alloy by electrodeposition, and the electrodeposition method includes direct current electrodeposition and pulse electrodeposition.

specific Embodiment approach 3

[0030] Specific embodiment three: a method for preparing metal rhodium or rhodium alloy by electrodeposition described in specific embodiment one, in step (1), the concentration of rhodium ions in the complex solution of rhodium ions is 0.1~ 10 g / L; The rhodium ion is provided by one or more of rhodium sulfate, rhodium phosphate, rhodium chloride, rhodium iodide, rhodium nitrate, rhodium chloride, preferably rhodium sulfate, rhodium chloride or Chlororhodium acid.

[0031] Embodiment 4: A method for preparing metal rhodium or rhodium alloys by electrodeposition described in Embodiment 1. In step (2), the dissimilar metal ions are copper, nickel, zinc, cobalt, iron, One or more of chromium, iridium, ruthenium, palladium, gold, silver, and use the complexing agent described in CN105906668B to prepare the corresponding complex.

[0032] Embodiment 5: A method for preparing metal rhodium or rhodium alloy by electrodeposition described in Embodiment 1. In step (3), the acid soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com