Fermentation type low-alcohol mulberry wine and processing method thereof

A technology of alcohol mulberry wine and processing method, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, pharmaceutical formulations, etc., can solve the problems of unsuitable use and high ethanol concentration, and achieves prevention of oxidation, reduction of potency, and enhancement of anti-oxidation. and bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

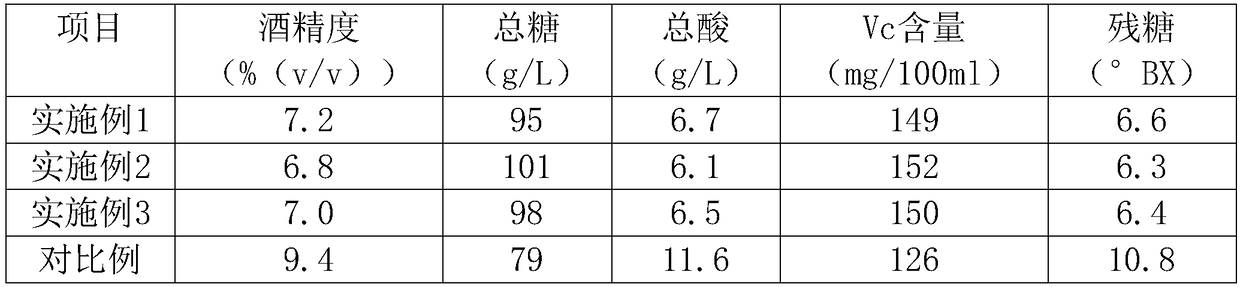

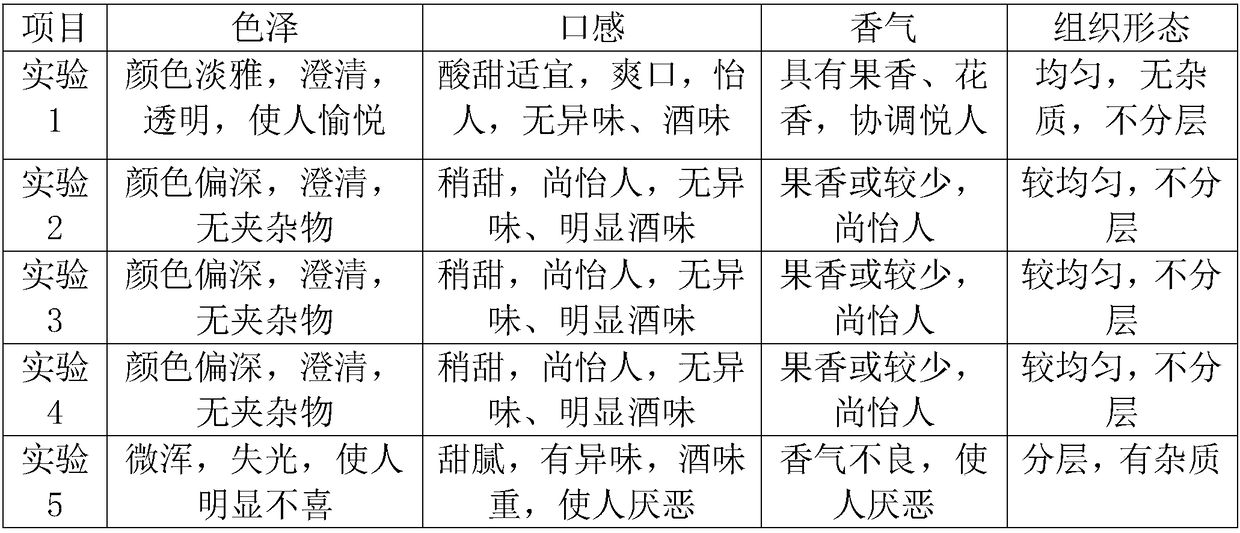

Examples

Embodiment 1

[0021] The experimenter uses the raw materials of the following weights to process a fermented low-alcohol mulberry wine. The formula of each raw material of the fermented low-alcohol mulberry wine is: 8 kg of mulberry juice, 9.5 kg of mulberry fruit, 4.6 kg of non-saccharomyces cerevisiae, and 4.1 kg of Saccharomyces cerevisiae , rape bee pollen 6.5kg, bellflower pulp 3.3kg, strawberry juice 4.9kg, apple juice 3.1kg, pectinase 2.85kg, amylase 2.25kg, wort lactic acid 3.43kg, raspberry leaves 4.01kg, lotus root leaves 3.05kg, Sodium polyphosphate 1.12kg, vitamin C 0.9kg, water 140kg.

[0022] The specific steps of the processing method of this fermented low-alcohol mulberry wine are realized according to the following three steps:

[0023] 1) Reflux extract raspberry leaves in ammonia water with a mass concentration of 4% for 2 times, each time for 45 minutes, to obtain raspberry leaf extract and residue P, and set aside; take apple juice and sufficient water to mix evenly, pu...

Embodiment 2

[0027] The experimenter uses the raw materials of the following weights to process a fermented low-alcohol mulberry wine. The formula of each raw material of the fermented low-alcohol mulberry wine is: 11kg mulberry juice, 11.5kg mulberry fruit, 5.1kg non-saccharomyces cerevisiae, 4.3kg Saccharomyces cerevisiae , rape bee pollen 8.5kg, bellflower pulp 3.8kg, strawberry juice 7.9kg, apple juice 4.6kg, pectinase 4.35kg, amylase 2.85kg, wort lactic acid 4.04kg, raspberry leaves 5.01kg, lotus root leaves 4.05kg, Sodium polyphosphate 1.74kg, vitamin C 1.1kg, water 170kg.

[0028] The specific steps of the processing method of this fermented low-alcohol mulberry wine are realized according to the following three steps:

[0029] 1) Reflux extract raspberry leaves in ammonia water with a mass concentration of 7% for 2 times, each time for 55 minutes, to obtain raspberry leaf extract and residue P, and set aside; take apple juice and enough water to mix evenly, put into a container Pu...

Embodiment 3

[0033] The experimenter uses the raw materials of the following weights to process a fermented low-alcohol mulberry wine. The formula of each raw material of the fermented low-alcohol mulberry wine is: 14kg mulberry juice, 13.5kg mulberry fruit, 5.6kg non-saccharomyces cerevisiae, 4.5kg Saccharomyces cerevisiae , Rape bee pollen 10.5kg, Bellflower pulp 4.3kg, Strawberry juice 10.9kg, Apple juice 6.1kg, Pectinase 5.85kg, Amylase 3.45kg, Wort lactic acid 4.65kg, Raspberry leaves 6.01kg, Lotus root leaves 5.05kg, Sodium polyphosphate 2.36kg, vitamin C 1.3kg, water 200kg.

[0034] The specific steps of the processing method of this fermented low-alcohol mulberry wine are realized according to the following three steps:

[0035] 1) Reflux extract raspberry leaves in ammonia water with a mass concentration of 9% for 2 times, each time for 65 minutes, to obtain raspberry leaf extract and residue P, and set aside; take apple juice and sufficient water to mix evenly, put into a contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com