A kind of preparation method of nano-nickel/array carbon nanotube composite material

A technology of carbon nanotubes and composite materials, which is applied in the direction of carbon nanotubes, nanocarbons, nanotechnology, etc., can solve the problems of easy high temperature oxidation, difficult dispersion of carbon nanotubes, and low interface compatibility, so as to achieve easy control and avoid premature The effect of wide compatibility of processing steps and interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of arrayed carbon nanotubes is as follows: the surface area is 2.5m 2 Light aluminum foil as the substrate, 3g of ferrocene as the catalyst, heated to 635°C under an inert atmosphere, hydrogen with a flow rate of 30ccm as the reducing agent, and ethylene with a flow rate of 120ccm as the carbon source at the same time, reacted for 1.5h, and stopped adding carbon Source, after naturally cooling down to room temperature, arrayed carbon nanotubes with a length of 200 μm, a tube inner diameter of 3.0 nm, and a layer number of 8 layers were obtained on the light aluminum foil.

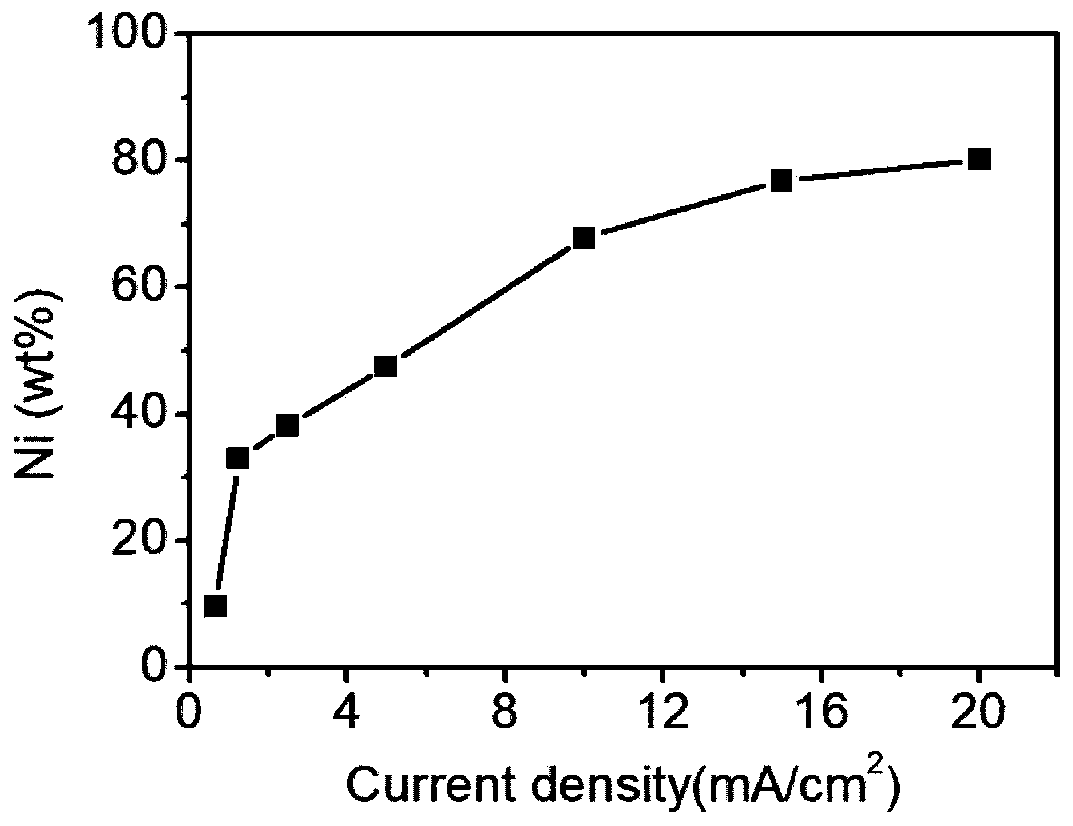

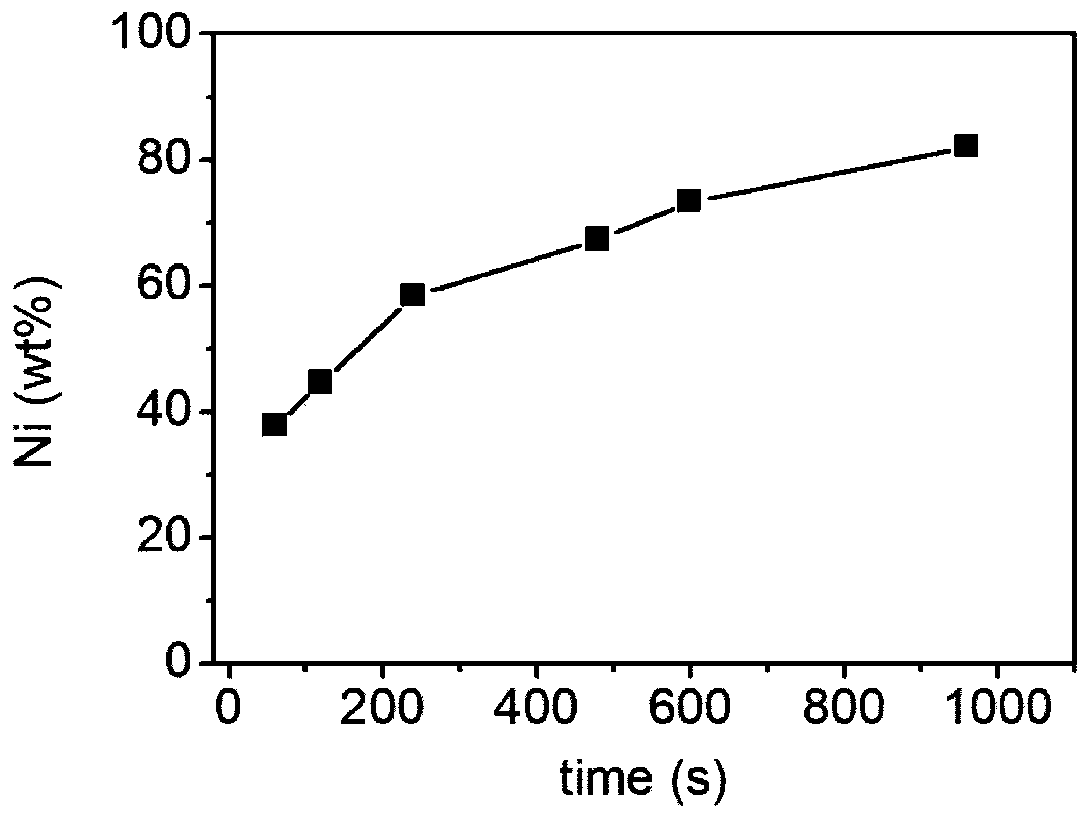

[0025] A preparation method of nano-nickel / array carbon nanotube composite material, the array carbon nanotube obtained by the above method is used as cathode, and 99.995% electrolytic nickel plate is used as anode, immersed in 120g / L nickel sulfate, 18g / L nickel chloride, 16g / L boric acid, 0.2g / L sodium dodecylbenzenesulfonate (SDS) mixed solution, 5mA / cm 2 The electric curr...

Embodiment 2

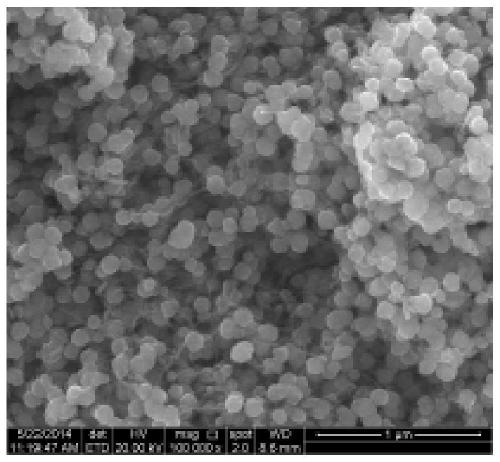

[0027] The preparation method of arrayed carbon nanotubes is as follows: the surface area is 4.5m 2Light aluminum foil as the substrate, 0.5g ferrocene as the catalyst, heated to 625°C in an inert atmosphere, hydrogen with a flow rate of 10ccm as the reducing agent, and acetylene with a flow rate of 50ccm as the carbon source, reacted for 30min, and stopped adding carbon source, after naturally cooling down to room temperature, arrayed carbon nanotubes ( figure 1 ).

[0028] A kind of preparation method of nano-nickel / array carbon nanotube composite material, with the array carbon nanotube obtained by the above method as cathode, 99.995% electrolytic nickel plate as anode, immersed in 270g / L nickel sulfamate, 30g / L nickel chloride , 10g / L boric acid mixed solution, 20mA / cm 2 The electric current 45min, obtains the nano-nickel particle that equivalent diameter is 30nm on the array carbon nanotube of cathode, forms nano-nickel / array carbon nanotube composite material, and the ...

Embodiment 3

[0030] The preparation method of arrayed carbon nanotubes is as follows: with a surface area of 8.0m 2 Corroded aluminum foil as the substrate, 3.5g of ferrocene as the catalyst, heated to 600°C in an inert atmosphere, and ethanol with a flow rate of 30mL / min as the carbon source, reacted for 1h, stopped adding the carbon source, and cooled down to room temperature naturally, that is Arrayed carbon nanotubes with a length of 100 μm, a tube inner diameter of 7.0 nm, and a layer number of 5 layers were obtained on the corroded aluminum foil.

[0031] A preparation method of nano-nickel / array carbon nanotube composite material, the array carbon nanotube obtained by the above method is used as a cathode, and the active nickel mesh with a sulfur content of 0.01-0.04% is an anode, immersed in 30g / L nickel sulfamate, 4g / L nickel chloride, 4g / L boric acid, 0.3g / L displacement agent LY-6813 (Tianjin Zhongsheng Surface Technology Co., Ltd.) 2 The electric current of 60min, on the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com