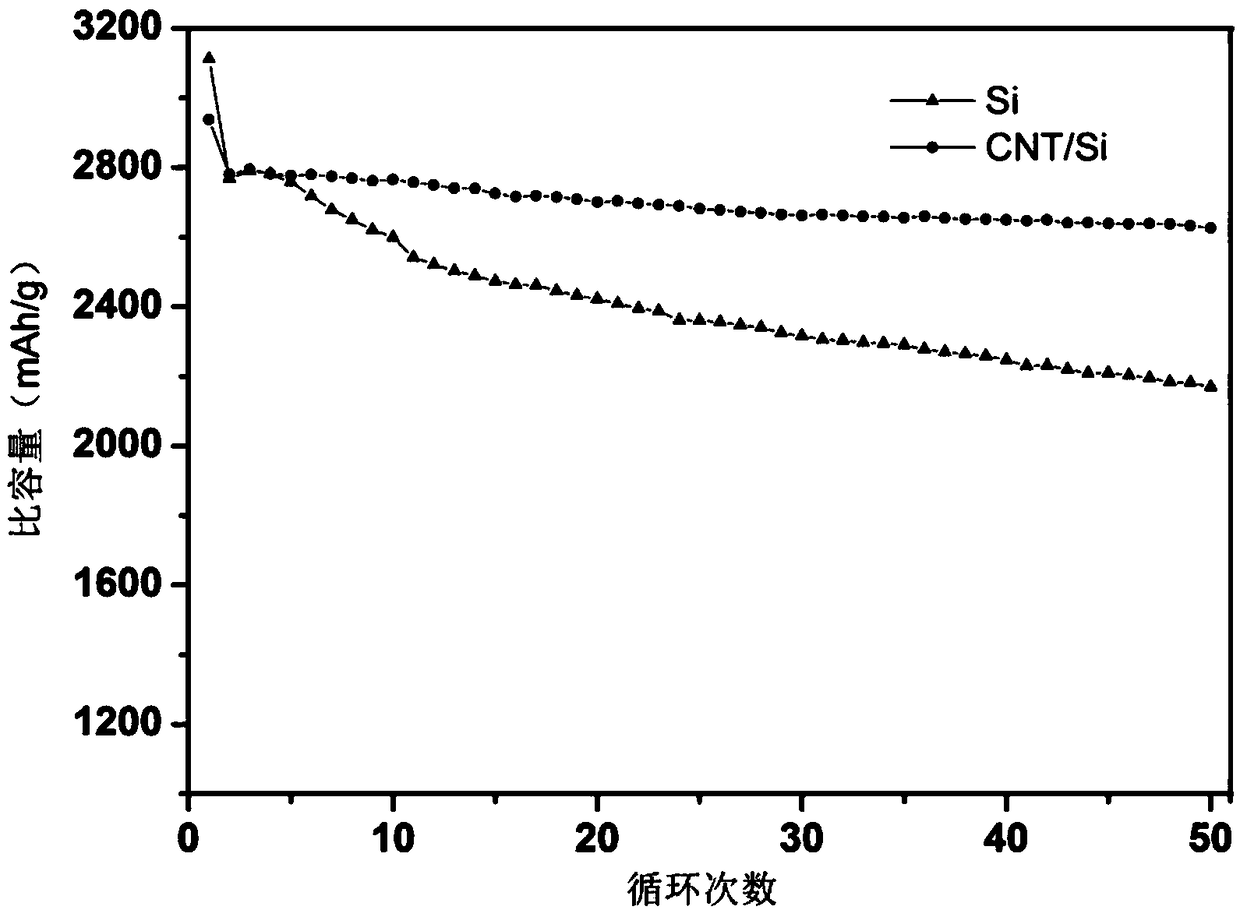

A silicon negative electrode material and a negative electrode sheet coated with carbon nanotubes, a preparation method thereof and a lithium ion battery

A technology of carbon nanotubes and negative electrode materials, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve problems such as poor cycle performance, uneven distribution of carbon nanotubes, detachment, etc., achieve stable electrochemical performance, and facilitate large-scale production The effect of large-scale production and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing a negative electrode sheet. The method comprises uniformly mixing the negative electrode material with a conductive agent, a binder and a solvent to obtain an electrode slurry, and coating the electrode slurry on the surface of a current collector, and drying Dry, wherein, the negative electrode material is the silicon negative electrode material covered with carbon nanotubes.

[0034] The main improvement of the preparation method of the negative electrode sheet provided by the present invention is to adopt a new negative electrode material, and the specific types of conductive agent, binder and solvent and their consumption with the negative electrode material and the like can be compared with the existing ones. The technique is the same. For example, specific examples of the conductive agent include, but are not limited to: at least one of super carbon black, graphene, carbon fiber and graphite. Specific exa...

Embodiment 1

[0041] Weigh 14g PEG (M W :1000) and 50g CA (C 6 h 8 o 7 ·H 2 (0), add 150ml dehydrated alcohol (95%), after magnetic stirring is to dissolving, then add 25g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), magnetically stirred for 50min to obtain a precursor solution. Add 50 g of nano-silicon (0.01-10 μm in particle size) to the precursor solution, stir magnetically for 2.5 hours, and filter the resulting slurry several times (washing with deionized water three times first, and finally with ethanol Washed twice, the same below), placed in a vacuum drying oven, dried at 60° C. for 5 hours to obtain a precursor-coated silicon material. Put the precursor-coated silicon material into the constant temperature zone of the tube furnace, heat it in the air atmosphere at 30 °C / min to 230 °C, keep it warm for 2 hours, let it cool naturally, and pass nitrogen gas for 20 min, close the tube furnace, and then 10°C / min to raise the temperature to 600°C, keep it warm for 2 hours, s...

Embodiment 2

[0047] Weigh 14g PEG (M W :1000) and 50g CA (C 6 h 8 o 7 ·H 2 (0), add 150ml dehydrated alcohol (95%), after magnetic stirring is to dissolving, then add 25g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), magnetically stirred for 50min to obtain a precursor solution. Add 45g of graphite (with a particle size of 16 μm) to the precursor solution, stir magnetically for 1 hour, slowly add 5g of nano-silicon (with a particle size of 200nm) under stirring, continue magnetic stirring for 2.5 hours, and suction filter the resulting slurry 1. After washing several times, put it in a vacuum drying oven, and dry at 80° C. for 5 hours to obtain a silicon material coated with a precursor. Put the precursor-coated silicon material into the constant temperature zone of the tube furnace, heat it in the air atmosphere at 30°C / min to 230°C, keep the temperature constant for 2 hours, let it cool naturally, and then pass nitrogen gas for 20min, close the tube furnace, and then The temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com