Preparation method of easily-degradable liquid state mulching film capable of improving fertility and maintaining water

A liquid mulch film, easy to degrade technology, applied in botany equipment and methods, plant protection, plant protection cover, etc., can solve the problem of low film formation and cohesion, poor water and fertilizer retention, premature dissolution, detachment Film and other problems, to achieve the effect of easy degradation, improved fertilizer preservation effect, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

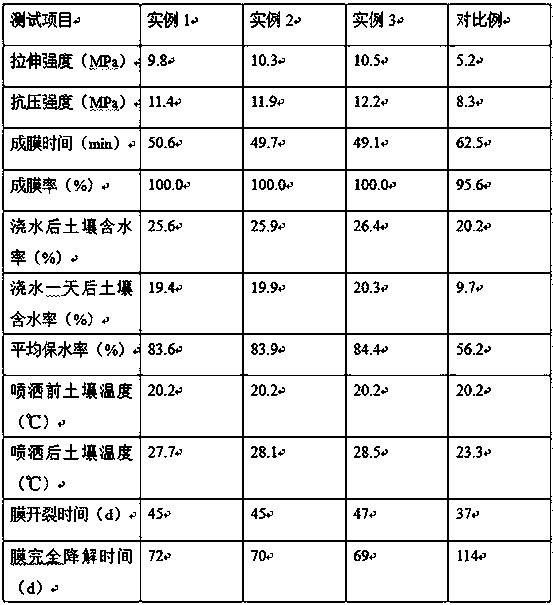

Examples

example 1

[0026]Ignite soybean straw to obtain straw ash, then mix natural coconut shell powder, straw ash, and water in a mass ratio of 2:1:3, place in a homogenizer for beating for 1 hour to obtain slurry, and mix 2.0L slurry, 400mL solid mass content Mix 20% biogas slurry, 20g peat, and 60g potassium nitrate into the fermenter, seal the fermenter, keep it in a greenhouse at 40°C for 8 days, take out the fermented liquid and put it in a water bath, add 100g of urea , 200mL of formaldehyde solution with a mass fraction of 37%, heated to 70°C, and stirred at a constant temperature for 3 hours to obtain a fattening pre-polyurea-formaldehyde glue, for later use; take 40g of sea shrimp shell powder and disperse it in 100mL of acetic acid solution with a mass fraction of 5% , add 2mL polysorbate-80 to the acetic acid solution, heat up to 70°C, stir and dissolve with a magnetic stirrer at a speed of 400r / min, and then use a high-speed disperser to disperse homogeneously at a speed of 5000r / mi...

example 2

[0028] Ignite soybean stalks to obtain straw ash, then mix natural coconut shell powder, straw ash, and water in a mass ratio of 2:1:3, place in a homogenizer for beating for 1 hour to obtain slurry, and mix 2.3L slurry, 450mL solid mass content Mix 20% biogas slurry, 23g peat, and 65g potassium nitrate into the fermenter, seal the fermenter, keep it in a greenhouse at 43°C for 9 days, take out the fermented liquid and put it in a water bath, add 110g of urea 1. 250mL of formaldehyde solution with a mass fraction of 37%, heated to 73°C, and stirred at a constant temperature for 3 hours to obtain a fattening pre-polyurea-formaldehyde glue, for later use; take 45g of sea shrimp shell powder and disperse it in 110mL of an acetic acid solution with a mass fraction of 5%. , add 2mL polysorbate-80 to the acetic acid solution, heat up to 75°C, stir and dissolve with a magnetic stirrer at a speed of 450r / min, and then use a high-speed disperser to disperse homogeneously at a speed of 5...

example 3

[0030] Ignite soybean stalks to obtain straw ash, then mix natural coconut shell powder, straw ash, and water in a mass ratio of 2:1:3, place in a homogenizer for beating for 2 hours to obtain slurry, and mix 2.5L slurry, 500mL solid mass content Mix 20% biogas slurry, 25g peat, and 70g potassium nitrate into the fermenter, seal the fermenter, keep it in a greenhouse at 45°C for 10 days, take out the fermented liquid and put it in a water bath, add 120g of urea , 300mL of formaldehyde solution with a mass fraction of 37%, heated to 75°C, and stirred at a constant temperature for 4 hours to obtain a fattening pre-polyurea-formaldehyde glue, for later use; take 50g of sea shrimp shell powder and disperse it in 120mL of acetic acid solution with a mass fraction of 5% , add 3mL polysorbate-80 to the acetic acid solution, heat up to 80°C, stir and dissolve with a magnetic stirrer at a speed of 500r / min, and then use a high-speed disperser to homogeneously disperse at a speed of 6000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com