High selective separability nanofiltration membrane preparation method

A separation and nanofiltration membrane technology, which is applied in the field of preparation of highly selective separation nanofiltration membranes, can solve the problems of insufficient effective separation, lack of high divalent ion removal rate, low inorganic salt removal rate, etc., and achieve wide pH The effect of the range of values applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

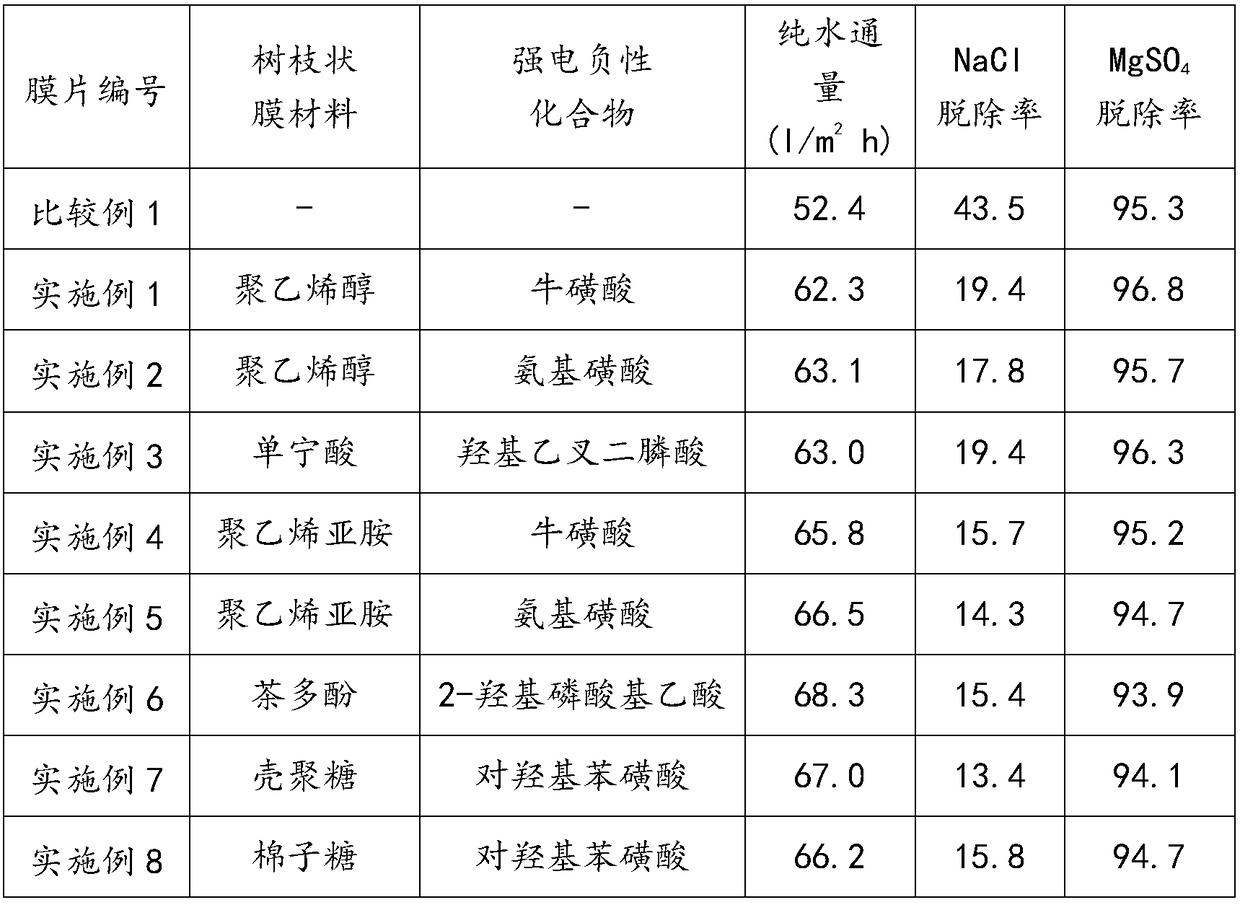

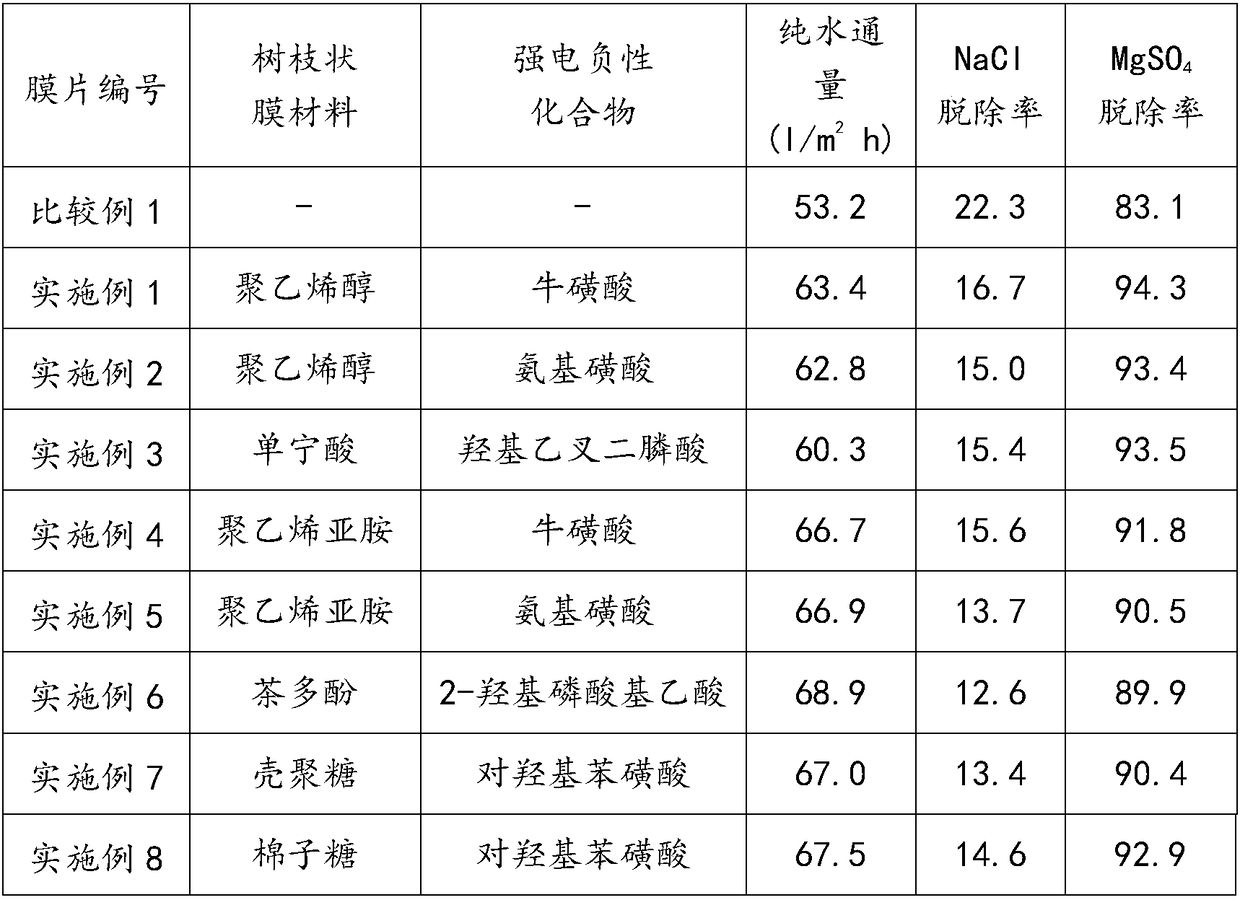

Examples

Embodiment 1

[0033] First, P-3500 polysulfone produced by Solvay in the United States was dissolved in N,N-dimethylacetamide to prepare a casting solution with a mass fraction of 20%. After vacuum defoaming, the polysulfone micropores were prepared by phase separation. membrane;

[0034] Secondly, the polysulfone microporous membrane is immersed in an aqueous phase solution containing 2wt% piperazine and 0.5wt% polyvinyl alcohol, and the polysulfone microporous membrane is mixed with 1wt% trimesoyl chloride after removing excess solution on the surface with a rubber roller. The organic phase solution was contacted for 1 minute, and heat-treated in an oven at 80° C. for 5 minutes to obtain a polypiperazine amide nanofiltration membrane.

[0035] Then the nascent polypiperazine amide nanofiltration membrane was contacted with an aqueous solution of taurine containing 0.5wt% (selecting pH=7.5 potassium dihydrogen phosphate / sodium hydroxide buffer solution) for 1 minute to carry out a secondar...

Embodiment 2

[0038]First, P-3500 polysulfone produced by Solvay in the United States was dissolved in N,N-dimethylacetamide to prepare a casting solution with a mass fraction of 20%. After vacuum defoaming, the polysulfone micropores were prepared by phase separation. membrane;

[0039] Secondly, the polysulfone microporous membrane is immersed in an aqueous phase solution containing 2wt% piperazine and 0.5wt% polyvinyl alcohol, and the polysulfone microporous membrane is mixed with 1wt% trimesoyl chloride after removing excess solution on the surface with a rubber roller. The organic phase solution was contacted for 1 minute, and heat-treated in an oven at 80° C. for 5 minutes to obtain a polypiperazine amide nanofiltration membrane.

[0040] Then the nascent polypiperazine amide nanofiltration membrane was contacted with 0.5wt% aqueous solution of sulfamic acid (pH=7.5 potassium dihydrogen phosphate / sodium hydroxide buffer solution) for 1 minute to carry out a secondary reaction to remov...

Embodiment 3

[0043] First, P-3500 polysulfone produced by Solvay in the United States was dissolved in N,N-dimethylacetamide to prepare a casting solution with a mass fraction of 20%. After vacuum defoaming, the polysulfone micropores were prepared by phase separation. membrane;

[0044] Secondly, the polysulfone microporous membrane is immersed in an aqueous phase solution containing 2wt% piperazine and 0.5wt% tannic acid, and the polysulfone microporous membrane is mixed with 1wt% trimesoyl chloride after removing excess solution on the surface with a rubber roller. The organic phase solution was contacted for 1 minute, and heat-treated in an oven at 80° C. for 5 minutes to obtain a polypiperazine amide nanofiltration membrane.

[0045] Then the nascent polypiperazine amide nanofiltration membrane was contacted with 0.5wt% hydroxyethylidene diphosphonic acid aqueous solution (pH=7.5 potassium dihydrogen phosphate / sodium hydroxide buffer solution) for 1 minute to carry out secondary react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com