Polypyrrole/copper phosphide composite material and preparation method thereof

A composite material and copper phosphide technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., to achieve great application prospects and controllable reaction processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

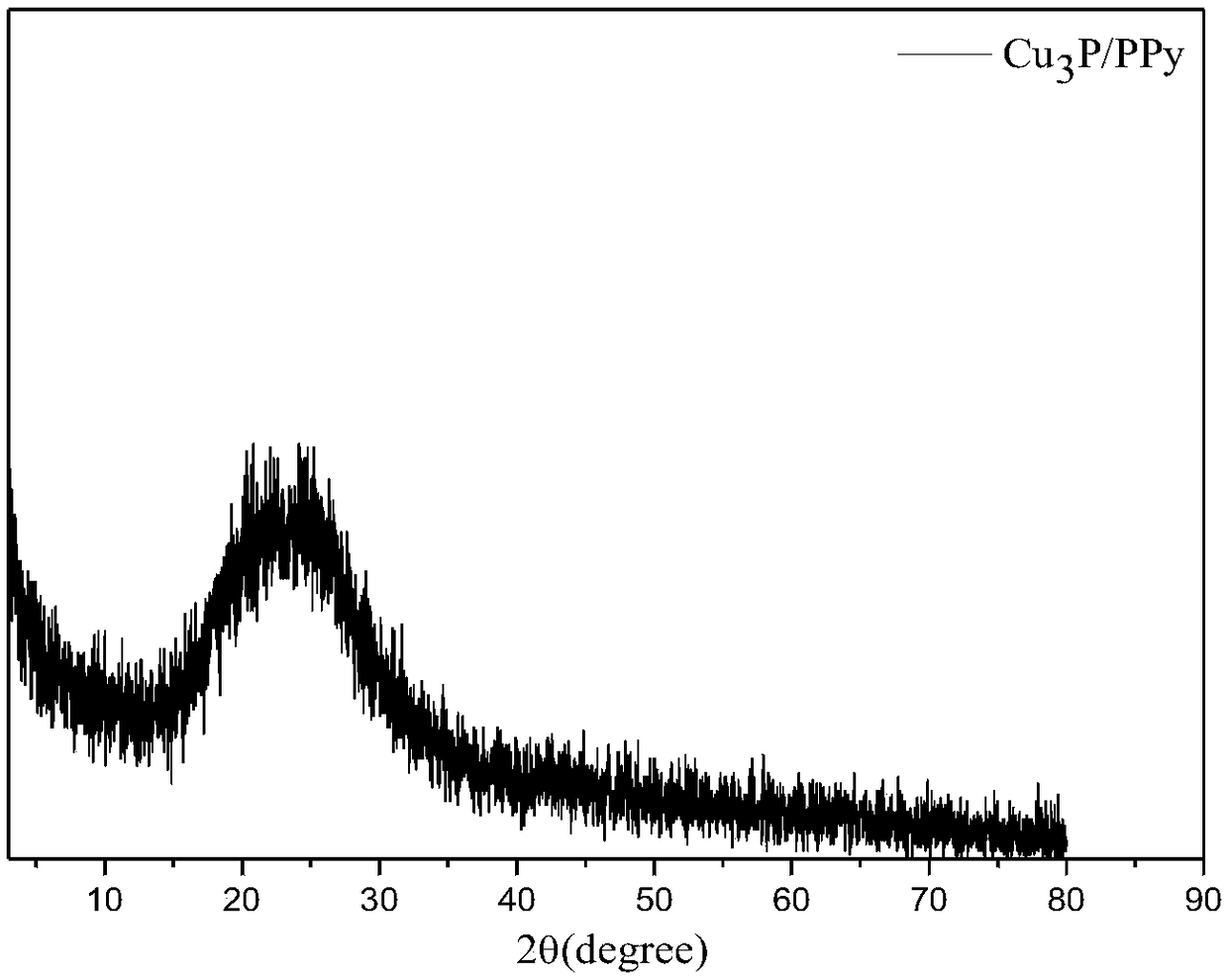

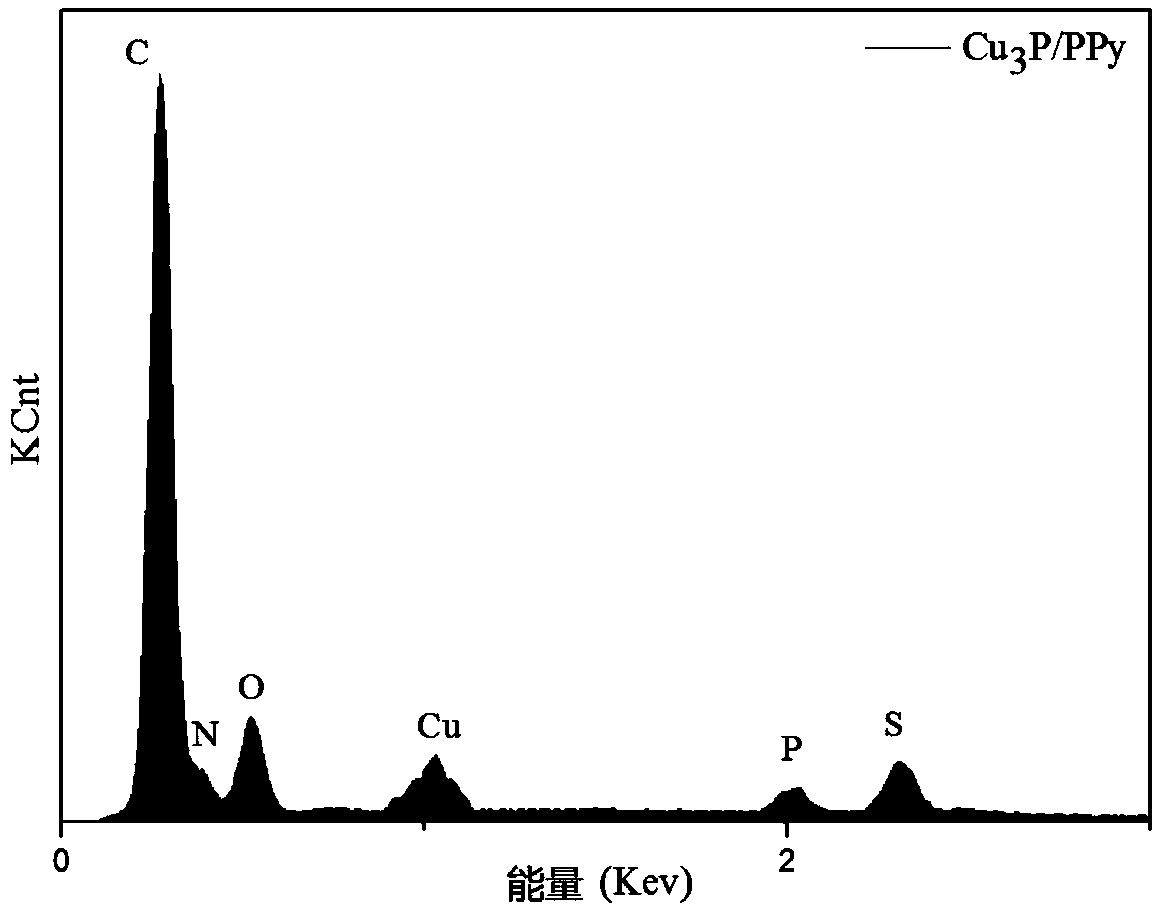

[0030] The preparation method of this material comprises the following steps:

[0031] Step 1, prepare copper phosphide (Cu 3 P)Material

[0032] Dissolve cetyltrimethylbromide (CTAB) in N,N-dimethylformamide (DMF), the ratio of solid to liquid is (0.05~0.1) g: 30mL, stir evenly with magnetic force, then add copper salt , where the copper salt provides Cu 2+ The raw material is any one of copper sulfate pentahydrate, copper chloride dihydrate, and copper nitrate trihydrate. The ratio of the added copper salt and CTAB is (1~2)mmol:(0.05~0.1)g, stir evenly with magnetic force, transfer the evenly stirred solution to a stainless steel reaction kettle lined with polytetrafluoroethylene, add white phosphorus (P 4 ), adding P 4 The molar ratio with copper salt is (2-3): 1, adding P 4 Afterwards, hydrothermally react at 160-180°C for 16 hours, cool naturally to room temperature after the reaction, and obtain a black precipitate, wash the black precipitate three times in the orde...

Embodiment 1

[0041] Step 1, dissolve 0.1g of cetyltrimethyl bromide (CTAB) in 30mL of N,N-dimethylformamide (DMF), the ratio of solid to liquid is 0.1g: 30mL, stir evenly with magnetic force, then add 1mmol Copper sulfate pentahydrate was magnetically stirred until it was completely dissolved, and the resulting solution was transferred to a 50mL stainless steel reaction kettle, and then 0.248g (2mmol) of P 4 , Reacted at 180°C for 16h. After the reaction, the reaction kettle was naturally lowered to room temperature, and a black precipitate was obtained, which was washed three times with ethanol, deionized water, benzene, and ethanol respectively, and finally dried in a vacuum oven at 60°C for 24 hours to obtain a black product Cu 3 p.

[0042] Step 2: 0.03g of Cu prepared in step 1 3 P was ultrasonically dispersed in 50mL deionized water, then transferred to a three-necked flask, and 0.3g of pyrrole monomer and sodium p-hydroxybenzenesulfonate were added at 0°C. The molar ratio of pyrro...

Embodiment 2

[0045] The tensio-active agent in the step 2 of embodiment 1 is sodium lauryl sulfate, and other conditions are constant, and the product appearance that obtains remains unchanged, compares with embodiment 1, specific capacitance is lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com