Circulating utilization device and method for preparing charcoal-based organic fertilizer by fixed bed straw carbonizing

A technology of straw carbonization and straw molding equipment, which is applied in the direction of steam generation method using heat carrier, organic fertilizer, fertilization equipment, etc., can solve the problems of low combustion temperature, high cellulose content, low melting point of biomass ash, etc., and achieve improvement Effects of improving fermentation efficiency, improving void structure, and improving charcoal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

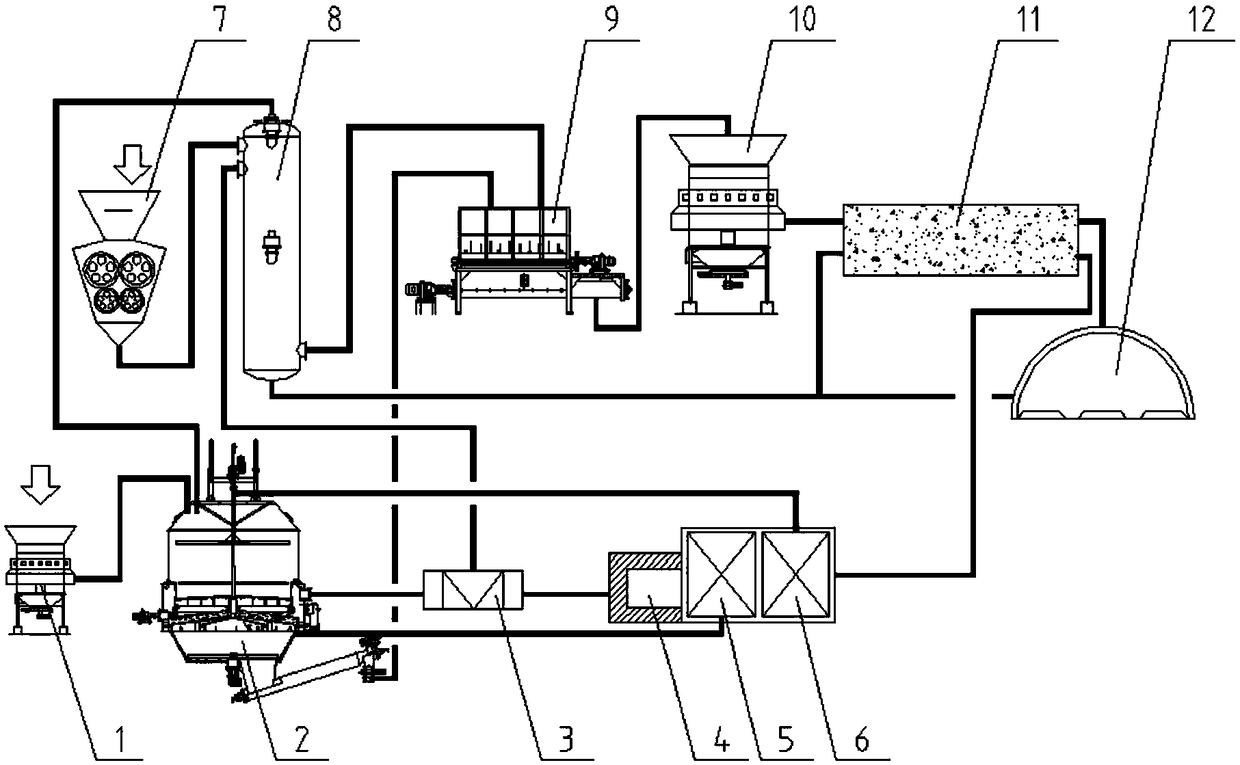

[0037]After the corn stalks are briquetted, they are sent to a fixed-bed straw carbonization device, where they are carbonized at 800°C to produce straw charcoal and straw gas with a carbon content of 45%, and the biomass extract carried in the gas is collected at 160°C. Combustion of straw gas produces high-temperature flue gas. After heat exchange, the flue gas generates steam and 800°C high-temperature air, and discharges 400°C flue gas for use by the drying device. Part of the dried flue gas is sent to the fermentation device, and the waste heat is used to ensure The fermentation temperature is kept stable at 80°C, and the other part is sent to the biosorption device to ensure that the temperature inside the biosorption device is 40°C.

[0038] 35% swill, 10% chicken manure, 5% cow dung, 13% cassava flour, and 7% leaves are mixed in the organic matter pretreatment device, crushed to a suitable particle size, fungi and water are added, and then sent to the fermentation devic...

Embodiment 2

[0040] After the rice straw is briquetted, it is sent to a fixed-bed straw carbonization device, which is carbonized at 350°C to produce straw charcoal and straw gas with a carbon content of 53%, and the biomass extract carried in the gas is collected at 20°C. Combustion of straw gas produces high-temperature flue gas. After heat exchange, the flue gas generates steam and high-temperature air at 150°C, and the flue gas at 150°C is discharged for use by the drying device. Part of the dried flue gas is sent to the fermentation device, and the residual heat is used to ensure The fermentation temperature is kept stable at 40°C, and the other part is sent to the biosorption device to ensure that the temperature in the biosorption device is 20°C.

[0041] 18% of human manure, 11% of rabbit manure, 13% of furfural slag, 21% of distiller's grains, and 22% of bacterial bag waste are mixed in the organic matter pretreatment device, crushed to a suitable particle size, and then sent to th...

Embodiment 3

[0043] After the sorghum straw is briquetted, it is sent to a fixed-bed straw carbonization device, which is carbonized at 550°C to produce straw charcoal and straw gas with a carbon content of 55%, and the biomass extract carried in the gas is collected at 80°C. Combustion of straw gas produces high-temperature flue gas. After heat exchange, the flue gas generates steam and 350°C high-temperature air, and discharges 210°C flue gas for use in the drying device. Part of the dried flue gas is sent to the fermentation device, and the residual heat is used to ensure The fermentation temperature is kept stable at 53°C, and the other part is sent to the biosorption device to ensure that the temperature in the biosorption device is 26°C.

[0044] 7% of moldy feed, 16% of medicinal residue, 3% of soy sauce residue, 45% of sludge, and 21% of rotten fruits and vegetables are mixed in the organic matter pretreatment device, crushed to a suitable particle size, fungi and water are added, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com