Modified polyurethane composition with heat resistance

A technology of polyurethane and composition, applied in the field of modified polyurethane composition, can solve the problems of bare fibers, influence on performance, yellowing, etc., and achieve the effect of broad application prospects and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments, but the present invention is not limited to the following embodiments.

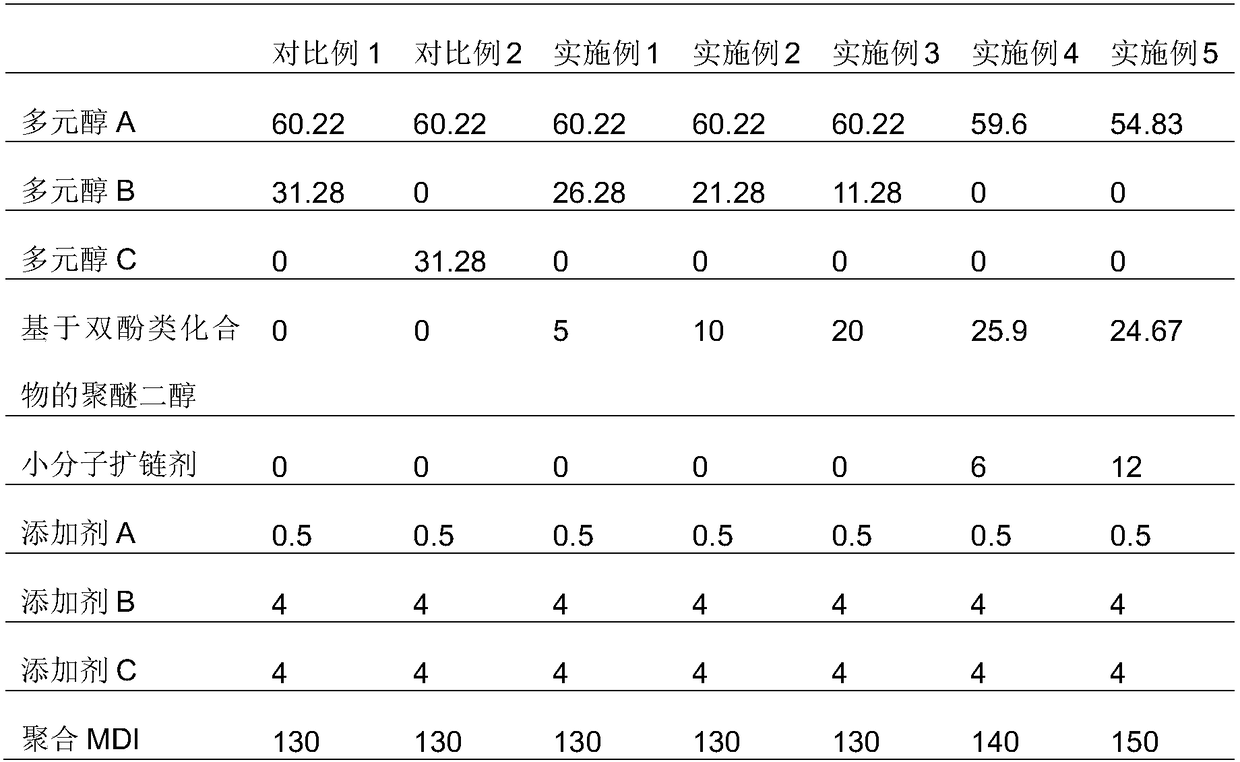

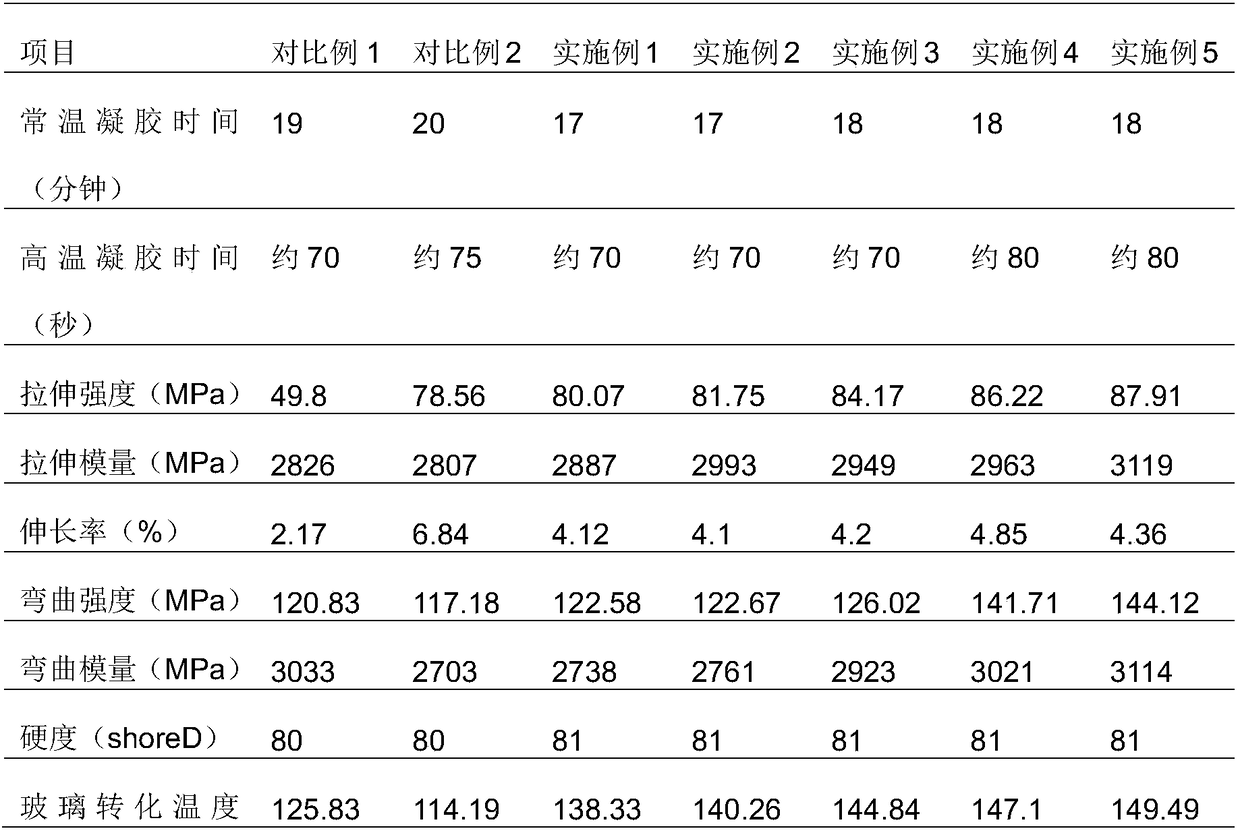

[0027] The components used in each of the following examples or comparative examples are as follows:

[0028] Polyol A: trifunctional polyol prepared by polymerization reaction with propylene oxide with glycerol as the initiator, the hydroxyl value is 670mgKOH / g;

[0029] Polyol B: trifunctional polyol prepared by polymerization reaction with propylene oxide with glycerol as the initiator, the hydroxyl value is 280mgKOH / g;

[0030] Polyol C: Propylene glycol is used as an initiator, and a difunctional polyol prepared by polymerization with propylene oxide has a hydroxyl value of 280 mgKOH / g;

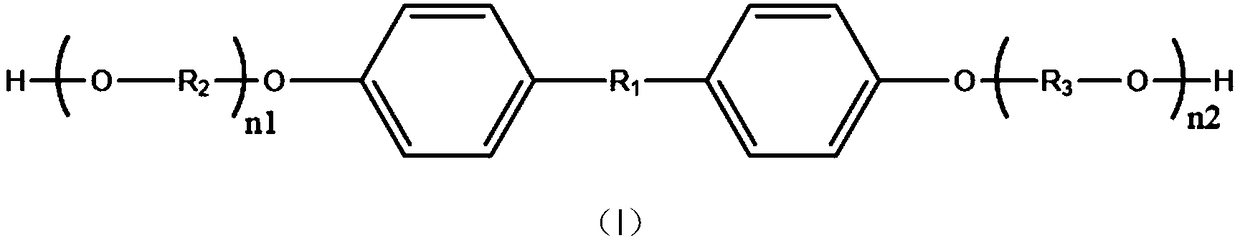

[0031] Polyether diol based on bisphenol compounds: Bisphenol A is the initiator, the 2 functional polyols prepared by the polymerization of propylene oxide, the hydroxyl value is 280mgKOH / g; See structural formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com