A kind of aluminum fluoride and its preparation method and application

A technology of aluminum fluoride and aluminum salt, which is applied in the direction of aluminum fluoride, aluminum halide, structural parts, etc., can solve the problems of unfavorable human health, toxicity, and many impurities in the product, and achieve excellent electrochemical performance, mild reaction conditions, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method for aluminum fluoride, comprising the steps of:

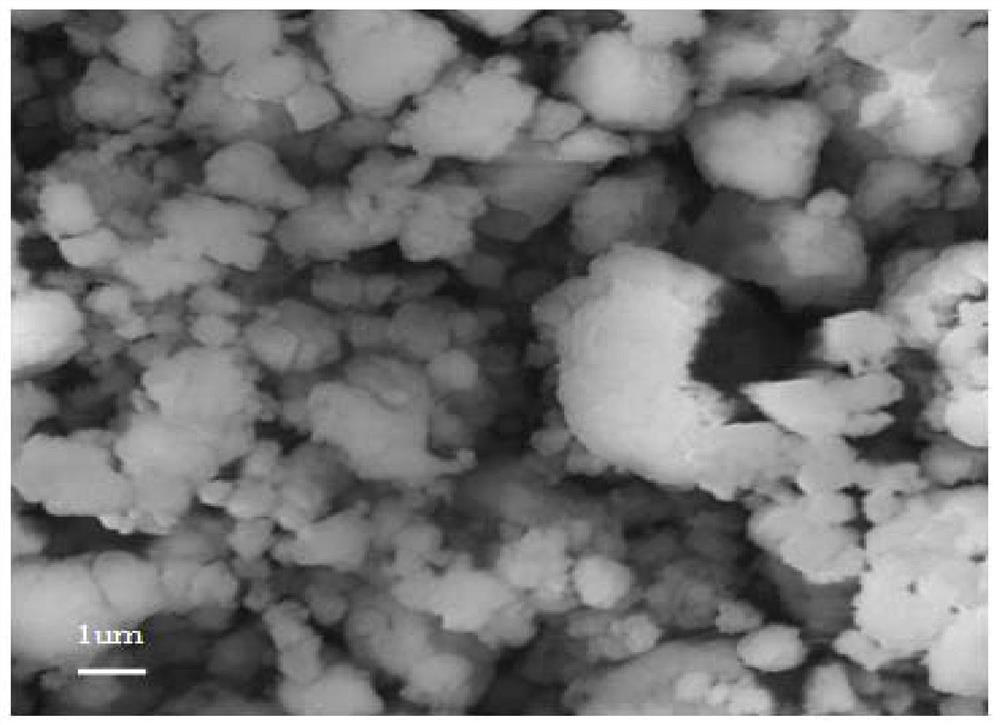

[0052] 1) Weigh 10g of aluminum nitrate nonahydrate into 30mL of deionized solution, stir evenly at 100°C, slowly add 2.96g of ammonium fluoride, stir evenly, and obtain a mixed solution;

[0053] 2) Heating the mixed solution at 80°C for 2h, then transferring to room temperature to stand for crystallization for 10h, suction filtration and washing with ethanol for 3 times to obtain white crystals, and drying the white crystals in a blast oven at 100°C for 10h to obtain the precursor;

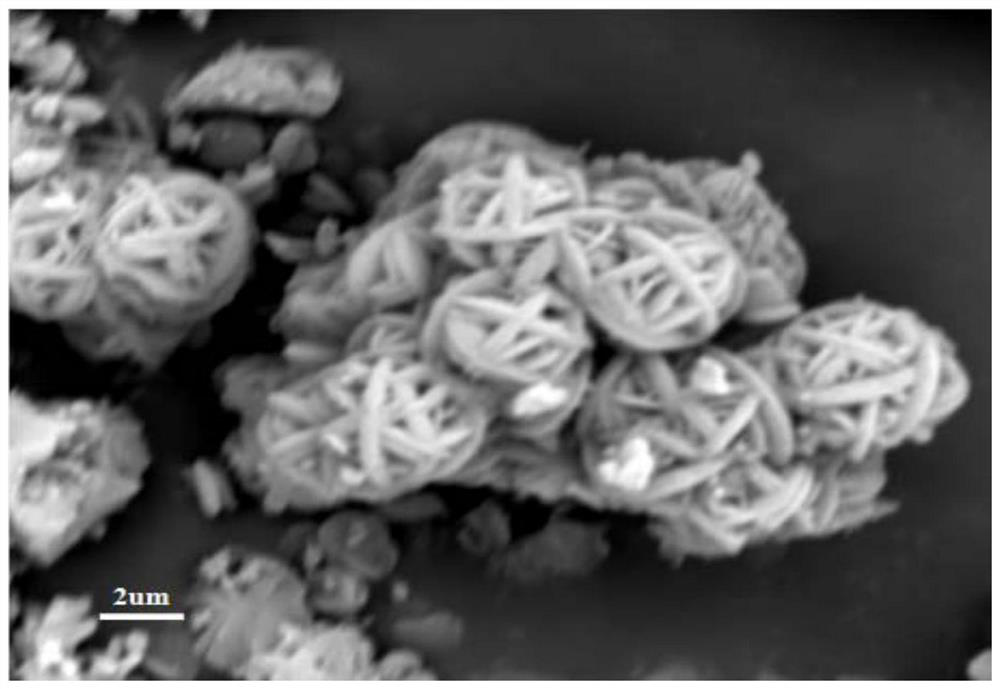

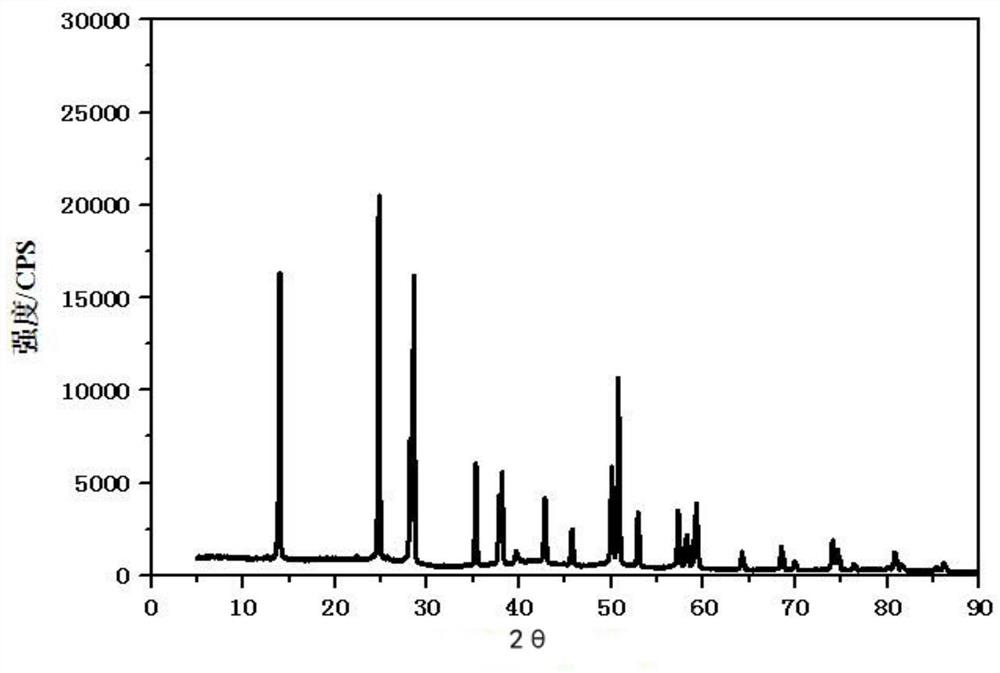

[0054] 3) Put the precursor in a tube furnace, heat up to 400°C at a rate of 5°C / min, keep it warm for 3 hours, and cool down to room temperature naturally to obtain aluminum fluoride.

Embodiment 2

[0056] A preparation method for aluminum fluoride, comprising the steps of:

[0057] 1) Weigh 10g of aluminum nitrate nonahydrate into 30mL of deionized solution, stir evenly at 100°C, then slowly add 3.94g of ammonium fluoride, stir evenly, to obtain a mixed solution;

[0058] 2) Heating the mixed solution at 80°C for 2h, then transferring to room temperature to stand for crystallization for 10h, suction filtration and washing with ethanol for 3 times to obtain white crystals, and drying the white crystals in a blast oven at 100°C for 10h to obtain the precursor;

[0059]3) Put the precursor in a tube furnace, heat up to 400°C at a rate of 5°C / min, keep it warm for 3 hours, and cool down to room temperature naturally to obtain aluminum fluoride.

Embodiment 3

[0061] A preparation method for aluminum fluoride, comprising the steps of:

[0062] 1) Weigh 13g of aluminum nitrate nonahydrate into 30mL of deionized solution, stir evenly at 100°C, then slowly add 3.85g of ammonium fluoride, stir evenly, to obtain a mixed solution;

[0063] 2) Heating the mixed solution at 80°C for 2h, then transferring to room temperature to stand for crystallization for 10h, suction filtration and washing with ethanol for 3 times to obtain white crystals, and drying the white crystals in a blast oven at 100°C for 10h to obtain the precursor;

[0064] 3) Put the precursor in a tube furnace, heat up to 450°C at a rate of 5°C / min, keep it warm for 3 hours, and cool down to room temperature naturally to obtain aluminum fluoride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com