Method for producing battery-grade nickel sulfate by taking nickel oxide as raw material

A technology of nickel oxide and nickel sulfate, applied in nickel sulfate and other directions, can solve the problems of equipment corrosion, high raw material cost, large consumption of fluoride salt, etc., and achieve the effects of low cost, resource saving and short extraction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

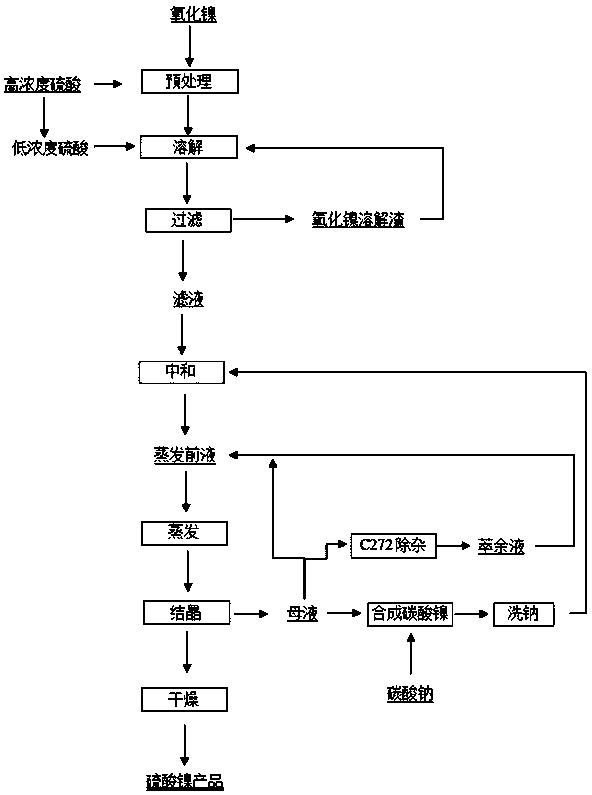

Method used

Image

Examples

Embodiment 1

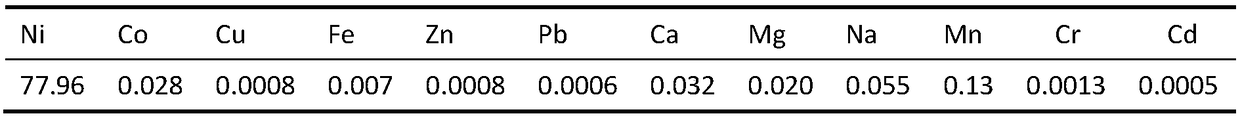

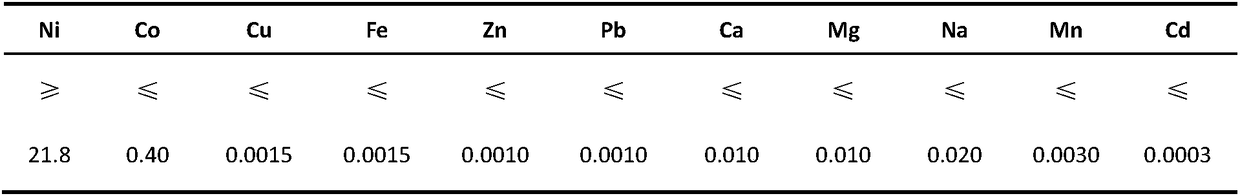

[0047] 1. Nickel oxide dissolution

[0048] Nickel oxide is pretreated with sulfuric acid with a hydrogen ion concentration of 12mol / L, and the pretreated nickel oxide is obtained by solid-liquid separation. The pretreatment temperature is 90°C, the volume of sulfuric acid with a hydrogen ion concentration of 12mol / L is 2L, and nickel oxide is 0.5kg. The pretreated nickel oxide is dissolved in sulfuric acid with a hydrogen ion concentration of 5 mol / L, the volume of sulfuric acid with a hydrogen ion concentration of 5 mol / L is 2.35 L, nickel oxide is 0.47 kg, the reaction temperature is 90 ° C, the reaction time is 6 hours, and hydrogen is obtained by filtration Acid-containing nickel sulfate solution with 0.46mol / L ions and 133g / L nickel ions.

[0049] 2. Synthesis of nickel carbonate with low calcium, magnesium and sodium content

[0050] Use pure water to configure sodium carbonate solution 120g / L, nickel sulfate solution 60g / L, synthesis temperature 80°C, synthesis pH mai...

Embodiment 2

[0057] 1. Nickel oxide dissolution

[0058] The nickel oxide is pretreated with sulfuric acid with a hydrogen ion concentration of 10mol / L, and the pretreated nickel oxide is obtained by solid-liquid separation. The pretreatment temperature is 80°C, the volume of sulfuric acid with a hydrogen ion concentration of 10mol / L is 1.8L, and the nickel oxide is 0.6 kg; use sulfuric acid with a hydrogen ion concentration of 4.5mol / L to dissolve the pretreated nickel oxide, the volume of sulfuric acid with a hydrogen ion concentration of 4.5mol / L is 2.2L, nickel oxide is 0.56kg, the reaction temperature is 80°C, and the reaction time is 8 hours. Filtrate to obtain the acid-containing nickel sulfate solution with hydrogen ion 0.43mol / L and nickel ion content 119g / L.

[0059] 2. Synthesis of nickel carbonate with low calcium, magnesium and sodium content

[0060] Use pure water to configure sodium carbonate solution 100g / L, nickel sulfate solution 50g / L, synthesis temperature 70°C, synth...

Embodiment 3

[0067] 1. Nickel oxide dissolution

[0068] Nickel oxide is pretreated with sulfuric acid with a hydrogen ion concentration of 8 mol / L, and the pretreated nickel oxide is obtained by solid-liquid separation. The pretreatment temperature is 70°C, the volume of sulfuric acid with a hydrogen ion concentration of 10 mol / L is 0.5 L, and the nickel oxide is 0.5 kg, using sulfuric acid with a hydrogen ion concentration of 3.5mol / L to dissolve the pretreated nickel oxide, the solid ratio is 3:1 (2.7L of nickel-containing sulfuric acid, 0.45kg of pretreated nickel oxide, 0.45kg of nickel oxide dissolved slag, of which nickel oxide The dissolved slag was obtained from the last filtering reaction and was reused), the reaction temperature was 70° C., the reaction time was 8 hours, and the acid-containing nickel sulfate solution of hydrogen ion 0.32mol / L and nickel ion content 93.32g / L was obtained by filtration.

[0069] 2. Synthesis of nickel carbonate with low calcium, magnesium and sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com