Colored high-strength polyethylene fibers and preparation method thereof

A high-strength polyethylene and polyethylene fiber technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of heat resistance, poor creep and oxidation resistance, low critical shear rate, and difficult molding and processing. and other problems, to achieve the effect of good compatibility, simple and easy dyeing, and improved color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

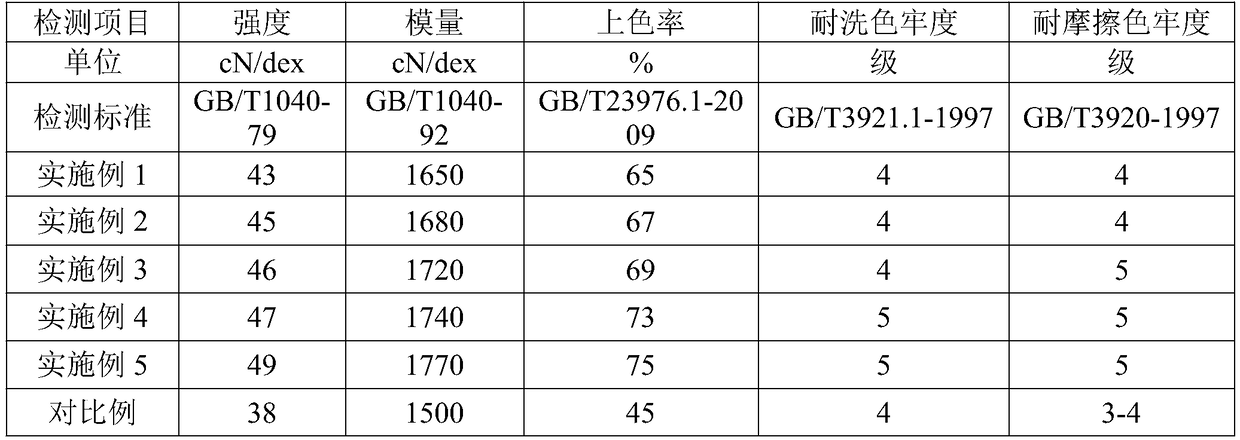

Examples

Embodiment 1

[0035] A preparation method of colored high-strength polyethylene fibers, comprising the steps of:

[0036] S1: 10kg of ultra-high molecular weight polyethylene, 0.5kg of surface-modified nano-boron fiber, 2kg of ultra-high molecular weight polyethylene fiber grafted on the surface of glycerol methacrylate, 0.1kg of Lanna free and easy green B, dodecylbenzenesulfonic acid 0.2 kg of sodium was added to 70 kg of tetralin to form a dispersion, and then the dispersion was added to a twin-screw extruder for heating to make it swell and dissolve, and the temperature was controlled at 250°C to obtain spinning stock solution A;

[0037] S2: Add 0.5kg of surface-modified nano-boron fibers, 10kg of ultra-high molecular weight polyethylene fibers grafted on the surface of glyceryl methacrylate, 0.1kg of Lanna free and easy green B, and 0.2kg of sodium dodecylbenzenesulfonate into tetrahydro Form a dispersion liquid in 70 kg of naphthalene, then add the dispersion liquid to the twin-screw...

Embodiment 2

[0047] A preparation method of colored high-strength polyethylene fibers, comprising the steps of:

[0048] S1: 10kg of ultra-high molecular weight polyethylene, 0.6kg of surface-modified nano-boron fiber, 2kg of ultra-high molecular weight polyethylene fiber grafted on the surface of glyceryl methacrylate, 0.15kg of Lanna free and easy yellow 4GN, polyoxypropylene polyvinyl glyceryl ether 0.2 kg was added to 80 kg of decahydronaphthalene to form a dispersion liquid, and then the dispersion liquid was added to a twin-screw extruder and heated to make it swell and dissolve, and the temperature was controlled at 260 ° C to obtain the spinning stock solution A;

[0049] S2: Add 0.6 kg of surface-modified nano-boron fibers, 10 kg of ultra-high molecular weight polyethylene fibers grafted on the surface of glyceryl methacrylate, 0.15 kg of Lanna Sata Yellow 4GN, and 0.2 kg of polyoxypropylene polyethylene glyceryl ether to decahydronaphthalene Form a dispersion liquid in 80kg, then...

Embodiment 3

[0059] A preparation method of colored high-strength polyethylene fibers, comprising the steps of:

[0060] S1: 10kg of ultra-high molecular weight polyethylene, 0.7kg of surface-modified nano boron fiber, 2kg of ultra-high molecular weight polyethylene fiber grafted on the surface of glycerol methacrylate, 0.2kg of phthalocyanine blue, and 0.2kg of nonylphenol polyoxyethylene ether Add it into 85kg of white oil to form a dispersion liquid, then add the dispersion liquid into a twin-screw extruder and heat it to make it swell and dissolve, and the temperature is controlled at 290°C to obtain the spinning stock solution A;

[0061] S2: Add 0.8 kg of surface-modified nano-boron fibers, 10 kg of ultra-high molecular weight polyethylene fibers grafted on the surface of glyceryl methacrylate, 0.2 kg of phthalocyanine blue, and 0.2 kg of nonylphenol polyoxyethylene ether to 85 kg of white oil to form Dispersion liquid, then add the dispersion liquid into the twin-screw extruder and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com