Negative electrode material, lithium ion battery and preparation method of negative electrode material

A negative electrode material, lithium titanate technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of material rupture, poor cycle performance of alloy materials, etc., and achieve high rate charge and discharge Performance, good market prospects, and the effect of improving charge transport characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

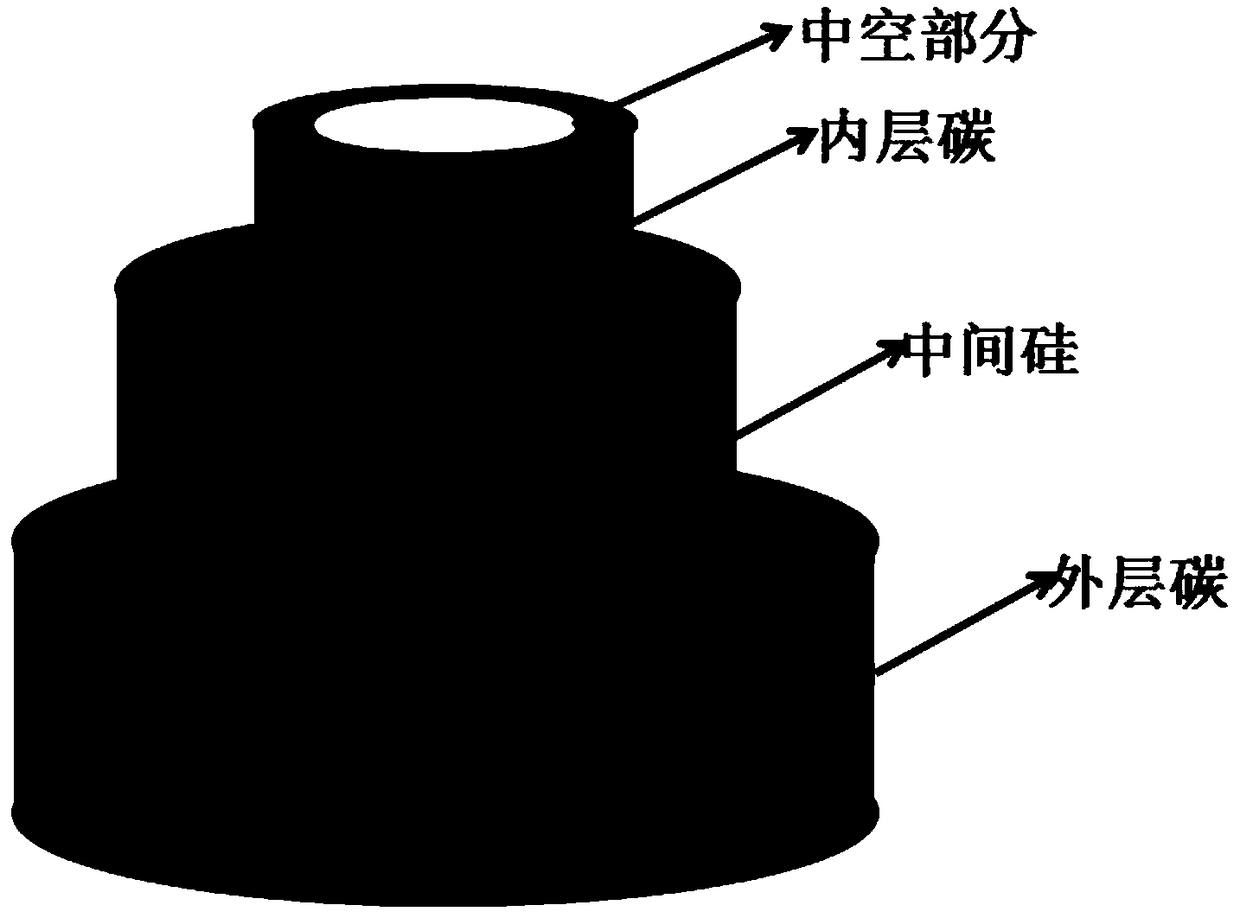

[0020] The preparation steps of the present invention include two parts: (1) preparation of carbon-silicon-carbon nano-arrays: preparing carbon-silicon-carbon nano-arrays using anodic aluminum oxide (AAO) templates and two-step chemical vapor phase method; (2) preparation of lithium titanate precursors Preparation: use Tween 80, Span 80, ethylene glycol, TiO 2 Powder, LiOH·H 2 O is used as a raw material to prepare the precursor of lithium titanate; (3) Preparation of carbon-silicon-carbon nanoarrays doped with lithium titanate: under the condition of mechanical stirring, the precursor of lithium titanate and the carbon-silicon-carbon nanoarray Mix well, and add the mixture into a high-pressure reactor for hydrothermal synthesis, then cool naturally to room temperature, filter, centrifuge, wash and dry the hydrothermal product in vacuum to obtain carbon silicon carbon nanoparticles doped with lithium titanate array.

[0021] The preparation concrete technology of the present...

Embodiment 1

[0030] Preparation of carbon-silicon-carbon nanoarrays: Place the template AAO in the corundum ark, put it into the heating zone of the tube furnace, raise the temperature to 800°C at 10°C / min under an argon atmosphere, and feed acetylene gas with a flow rate of 50sccm for 45min. Cool down naturally after 2 hours of heat preservation. The high-temperature gas-phase decomposition of acetylene yielded carbon nanotube arrays contained in the AAO template, which were subjected to plasma etching for 10 min and soaked in hydrofluoric acid for 2 h to remove the template AAO. Put the carbon nanotube array without the template AAO on the self-made aluminum support, then put it in the corundum ark, put it into the heating zone of the tube furnace, and use the mechanical pump and the diffusion pump to evacuate to 5Pa and 10Pa in turn. - 2 Pa. The temperature was programmed to rise to 800°C, the diffusion pump was stopped, and silane gas with a flow rate of 60 sccm was introduced for 45...

Embodiment 2

[0035] The formation method of the lithium-ion battery is the same as in Example 1, wherein the flow rate of silane gas in the preparation of the carbon-silicon-carbon nanoarray is 50 sccm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com