Carboxyl magnetic microspheres, preparation method and application

A technology of magnetic microspheres and carboxyl groups, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of insufficient tightness of the polymer layer, insufficient acid and alkali resistance, and cumbersome experimental operations, and achieve good monodispersity and high Good stability and batch repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Disperse 2 g of mesoporous microspheres and 2 g of polystyrene-maleic anhydride copolymer (PSMA) in 14 ml of chloroform, and add the PSMA-chloroform solution to the mesoporous microspheres after ultrasonic dispersion for 10 min Continue to ultrasonically disperse for 30 min; then successively wash with absolute ethanol and ultrapure water by centrifugation, and finally store in ultrapure water.

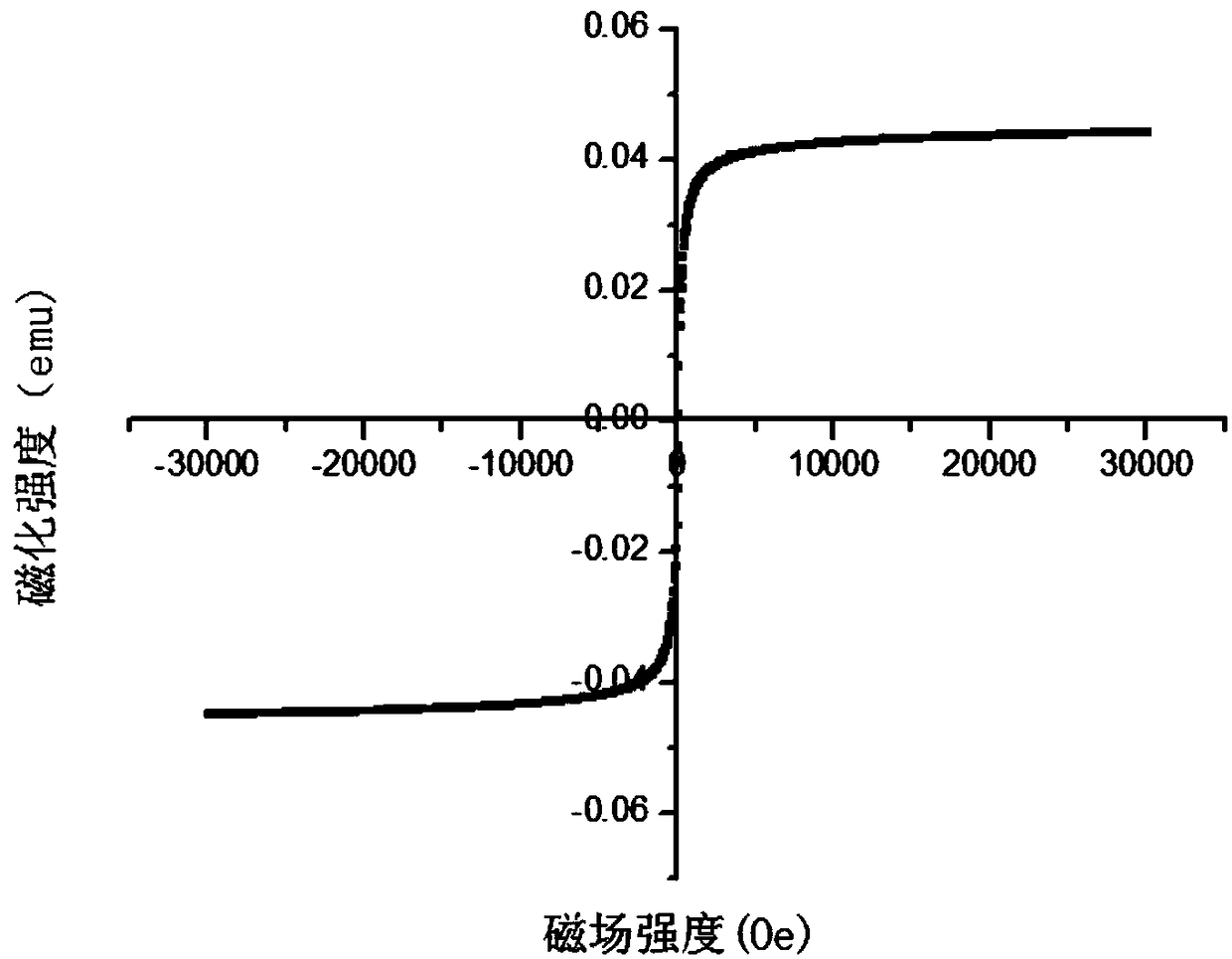

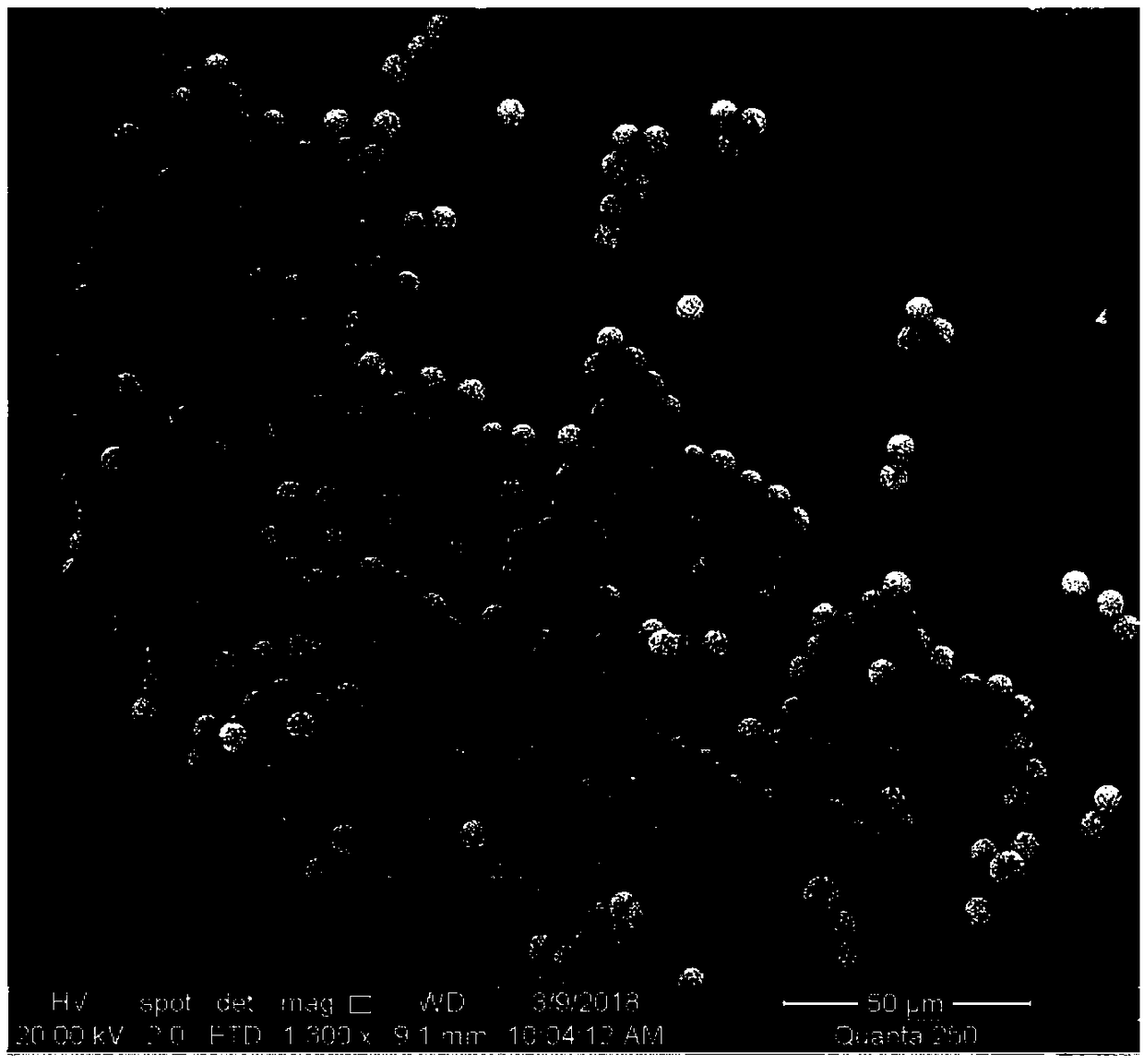

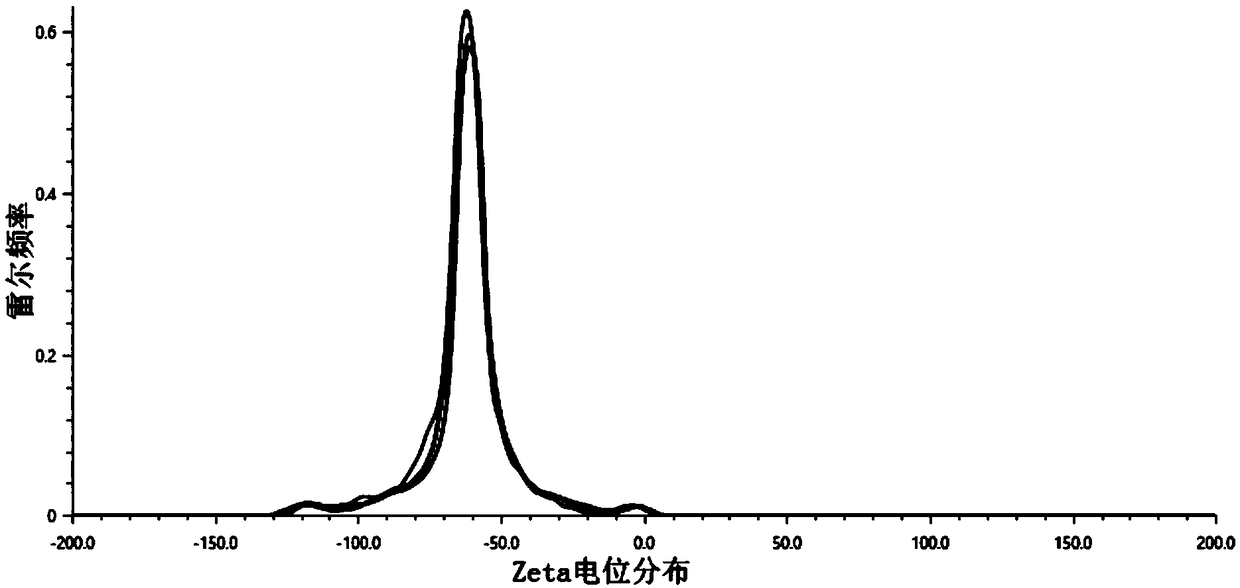

[0050] Weighed 0.696 g of ferric chloride hexahydrate and 0.44 g of ferrous sulfate heptahydrate into 1.5 L of ultrapure water, and then added 2 g of the above PSMA-modified mesoporous microspheres; after ultrasonic dispersion for 30 min, the mixture was added to Into a 5 L reactor, nitrogen gas was introduced, the temperature was raised to 65 °C, and 130 ml of sodium hydroxide solution (0.1 mol / L) was added to continue the reaction for 30 min; after the reaction was completed, it was washed with ultrapure water under centrifugation to obtain magnetic microspheres , the vibrati...

Embodiment 2

[0056] Disperse 2 g of mesoporous microspheres and 2 g of polyacrylic acid (PAA) in 14 ml of chloroform, and after ultrasonic dispersion for 10 min, add the PAA chloroform solution to the mesoporous microspheres and continue ultrasonic dispersion for 30 min; after the reaction Centrifuge and wash with absolute ethanol and ultrapure water in turn, and finally store in ultrapure water.

[0057] Weighed 0.696 g of ferric chloride hexahydrate and 0.44 g of ferrous sulfate heptahydrate into 1.5 L of ultrapure water, and then added 2 g of the above PSMA-modified mesoporous microspheres; after ultrasonic dispersion for 30 min, the mixture was added to Into a 5 L reactor, nitrogen gas was introduced, the temperature was raised to 65°C, and 260 ml of sodium hydroxide solution (0.1 mol / L) was added to continue the reaction for 30 min; after the reaction, it was washed with ultrapure water under centrifugation to obtain magnetic microspheres ;

[0058] Prepare 240 ml of polyethyleneimin...

Embodiment 3

[0063] Take 0.5 mg of magnetic microspheres modified with multiple carboxyl groups (hereinafter referred to as "magnetic beads") in 200 µl of phosphate buffer (PBT solution) (10mM pH7.40), wash three times, and change the PBT solution every 2 minutes. Then draw 200 µl of the prepared 50 mg / ml N-hydroxysuccinimide (NHS) (diluted in PBT) and place it in a centrifuge tube, add 50 mg / ml EDC·HCl200 µl at the same time, mix well and place in a rotating tube Rotate on the mixer for 15 min (at room temperature); adsorb the magnetic beads on the magnetic stand, remove the supernatant, and wash three times with 200 µl PBT solution. Then 200 µl of PBT solution was added, placed in a 37°C incubator and rotated on a rotary mixer for 2 h; the supernatant was removed by magnetic separation, washed three times with 200 µL of PBST (10 mM pH7.40), and dispersed in 500 µL of PBST. The streptavidin (SA) coupling amount of the magnetic beads is tested by the traditional BCA protein concentration t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com