Method and processing device thereof for removing hardness in water by combined multiple steps

A treatment device and hardness technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sewage treatment equipment and other directions, can solve the problems of high resin price, regeneration of waste liquid, large amount of mud production, and restricted development, etc. Achieve significant environmental and social effects, stable effluent turbidity, and reduced sludge volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

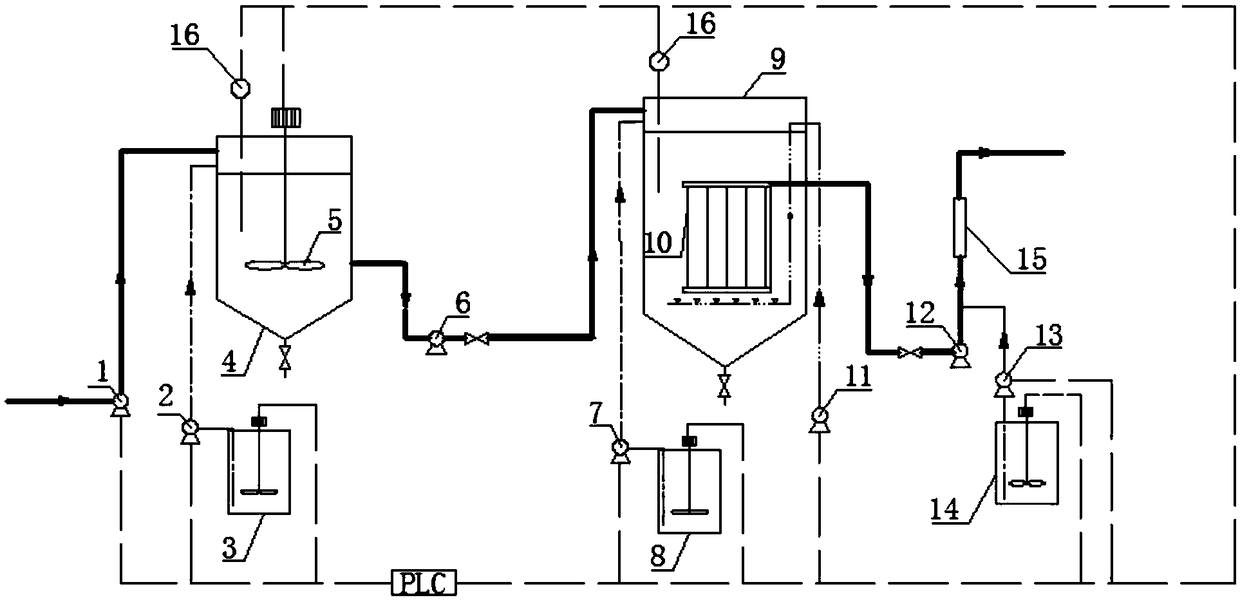

Image

Examples

Embodiment 1

[0029] The flow rate of the device is 0.63m 3 / h, the stirring intensity G value of the granulation stirring tank is 556s -1 , the residence time of the membrane separation tank is 35min, the calcium ion concentration of the raw water is 36mg / L, and the total hardness (calculated as CaCO 3 Count) is 140mg / L. When the experiment was started, 1000mg / L of calcium carbonate seeds prepared in advance were added to the granulation mixing tank. In the experiment, the dosage of sodium carbonate was 1000mg / L, and the dosage of ferric chloride (based on Fe 3+ ) was 3.5mg / L, stirred for 20min, and statically settled for 15min. The average concentration of calcium ions in the effluent was 0.91mg / L, and the removal rate was 97.5%; the average value of total hardness was 22.03mg / L, and the removal rate was 84.3%.

Embodiment 2

[0031] The flow rate of the device is 0.84m 3 / h, the stirring intensity G value of the granulation stirring tank is 556s -1 , the residence time of the membrane separation tank is 30min, the calcium ion concentration of the raw water is 32mg / L, and the hardness (calculated as CaCO 3 Count) is 130mg / L. When the experiment was started, 500 mg / L of calcium carbonate seeds prepared in advance were added to the granulation mixing tank. In the experiment, the dosage of sodium carbonate was 1000 mg / L, and the dosage of ferric chloride (based on Fe 3+ ) was 3.5mg / L, stirred for 15min, and statically settled for 10min. The average concentration of calcium ions in the effluent was 1.14mg / L, and the removal rate was 96.5%; the average value of total hardness was 23.07mg / L, and the removal rate was 82.3%. After the experiment, the average value of crystal particles increased from 32.42 μm to 142.00 μm.

Embodiment 3

[0033] The flow rate of the device is 0.63m 3 / h, the stirring intensity G value of the granulation stirring tank is 416s -1 , the residence time of the membrane separation tank is 35min, the calcium ion concentration of the raw water is 40mg / L, and the hardness (calculated as CaCO 3 Count) is 140mg / L. When the experiment was started, 400mg / L of calcium carbonate seeds prepared in advance were added to the granulation mixing tank. In the experiment, the dosage of sodium carbonate was 1000mg / L, and the dosage of ferric chloride (based on Fe 3+) was 3.5mg / L, stirred for 20min, and statically settled for 15min. The average concentration of calcium ions in the effluent was 1.16mg / L, and the removal rate was 97.1%; the average value of total hardness was 21.20mg / L, and the removal rate was 84.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com