Tile crack sealer and preparation method thereof

A jointing agent and ceramic tile technology, which is applied in the field of building materials, can solve the problems of polluting water sources, air and soil environment, difficult production process stability, ceramic tile foaming, etc., achieve good shrinkage performance, reduce the amount of cement used, and good water resistance waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

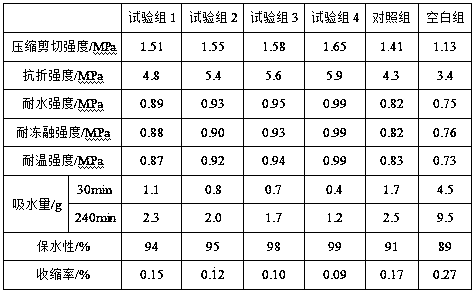

Examples

Embodiment 1

[0029] A ceramic tile jointing agent, its raw materials and parts by weight are as follows: 60 parts of cement, 50 parts of aggregate, 7 parts of expansion agent, 5 parts of water reducing agent, 6 parts of water retaining agent, 22 parts of redispersible latex powder, water-repellent 4 parts of agent, 2 parts of antibacterial agent, 3 parts of defoamer.

[0030] The cement is commercially available 42.5 grade ordinary Portland cement.

[0031] Aggregate is fly ash and tile polishing slag. Adding aggregate can not only fill the pores in the jointing agent and improve the pore structure, but also has a certain strengthening effect, increasing the number of beneficial hydration products, thereby improving the jointing agent. Strength and compactness, reduce the shrinkage and cracking of the jointing agent, and can make the jointing agent have good leveling property when it is mixed with water for joint filling.

[0032] The expansion agent is a calcium oxide-calcium sulfoalumin...

Embodiment 2

[0045] A ceramic tile grouting agent, its raw materials and parts by weight are as follows: 65 parts of cement, 55 parts of aggregate, 8 parts of expansion agent, 6 parts of water-reducing agent, 7 parts of water-retaining agent, 25 parts of redispersible latex powder, water-repellent 5 parts of agent, 3 parts of antibacterial agent, 4 parts of defoamer.

[0046] The cement is commercially available 42.5 grade ordinary Portland cement.

[0047] Aggregate is fly ash and tile polishing waste.

[0048] The expansion agent is calcium oxide-calcium sulfoaluminate composite expansion agent.

[0049] The water reducer is a naphthalene-based high-efficiency water reducer.

[0050] The water retaining agent is modified carboxypropyl methyl cellulose ether, and the viscosity of carboxypropyl methyl cellulose ether is 130,000 mPa·s.

[0051] The redispersible latex powder is styrene-acrylic latex powder, and its fineness is 190 mesh.

[0052] The water repellent is SHP-50 polysiloxan...

Embodiment 3

[0061] A ceramic tile jointing agent, its raw materials and their parts by weight are as follows: 70 parts of cement, 60 parts of aggregate, 9 parts of expansion agent, 7 parts of water-reducing agent, 8 parts of water-retaining agent, 30 parts of redispersible latex powder, water-repellent 6 parts of agent, 4 parts of antibacterial agent, 5 parts of defoamer.

[0062] The cement is commercially available 42.5 grade ordinary Portland cement.

[0063] Aggregate is fly ash and tile polishing waste.

[0064] The expansion agent is calcium oxide-calcium sulfoaluminate composite expansion agent.

[0065] The water reducer is a naphthalene-based high-efficiency water reducer.

[0066] The water retaining agent is modified carboxypropyl methyl cellulose ether, and the viscosity of carboxypropyl methyl cellulose ether is 140,000 mPa·s.

[0067] The redispersible latex powder is styrene-acrylic latex powder, and its fineness is 210 mesh.

[0068] The water repellent is SHP-50 polysil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com