Structure dressing with compounding of oxidized graphene and nanofiber and preparation method

A graphene composite, nanofiber technology, applied in dressings, non-adhesive dressings, coatings, etc., can solve the problems of promoting tissue healing, unable to provide wound moisturizing and nutrient supply, etc., to promote healing, avoid secondary infection, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

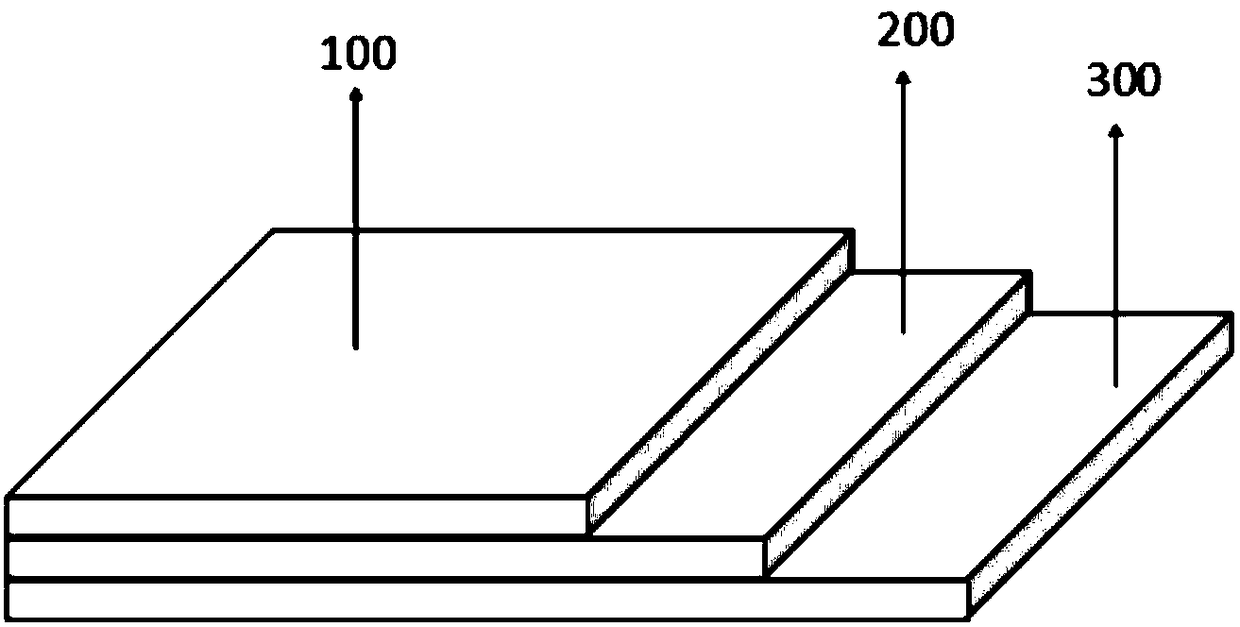

[0034] The preparation method of graphene oxide composite nanofiber structure dressing is as follows, as figure 1 Shown:

[0035] (1) Preparation of the supporting layer 100: Mix and stir the solution of nano-titanium dioxide, zeolite and PVA (the dosage ratio is 1:0.2:0.03) to form a slurry evenly, and apply it on the surface of non-woven fabric, fabric or mesh, and dry it before Spray a layer of 1% sodium alginate solution 50ml / m 2 , Dry at 50°C for 30 minutes to form a thin layer.

[0036] (2) Preparation of the middle layer 200: the surface of the thin layer prepared in step (1) is covered with the nanofibrous membrane PVA200. The weight of the fiber membrane is 2g / m 2 .

[0037] (3) Preparation of the inner layer 300: a slurry composed of graphene oxide, sodium alginate, zinc hyaluronate, vitamin B2, vitamin B12 and water is coated on the upper part of the middle layer. The mass composition of the slurry is as follows: 100 parts of water, 0.5 part of graphene oxide, ...

Embodiment 2

[0039] The preparation method of graphene oxide composite nanofiber structure dressing is as follows:

[0040] (1) Preparation of the support layer 100: Mix and stir the nano-titanium dioxide, zeolite and PVA (1:1:0.02) solution evenly to form a slurry, apply it on the surface of non-woven fabric, fabric or mesh, and spray a layer before drying 0.2% sodium alginate solution (25ml / m 2 ), dried at 45°C for 25 minutes to form a thin layer.

[0041] (2) Preparation of the middle layer 200: the surface of the thin layer is covered with a nanofibrous film of PVA. The weight of the fiber membrane is 2g / m 2 .

[0042] (3) Preparation of the inner layer 300: the upper part of the middle layer is coated with a slurry composed of graphene oxide, sodium alginate, zinc hyaluronate, vitamin B2, and vitamin B12. The composition of the slurry is as follows: 100 parts of water, oxidized 3 parts of graphene, 1.6 parts of sodium alginate, 2.6 parts of zinc hyaluronate, 0.10 parts of vitamin ...

Embodiment 3

[0044] The preparation method of graphene oxide composite nanofiber structure dressing is as follows:

[0045] (1) Preparation of the support layer 100: mix and stir the nano-titanium dioxide, zeolite and PVA (1:2.8:0.08) solution evenly to form a slurry, apply it on the surface of non-woven fabric, fabric or mesh, and spray a layer before drying 0.5% sodium alginate solution (80ml / m 2 ), dried at 70°C for 45min to form a thin layer.

[0046] (2) Preparation of the middle layer 200: the surface of the thin layer is covered with a nanofibrous film of PVA. The weight of the fiber membrane is 3.5g / m 2 .

[0047] (3) Preparation of the inner layer 300: the upper part of the middle layer is coated with a slurry composed of graphene oxide, sodium alginate, zinc hyaluronate, vitamin B2, vitamin B12, etc. The composition of the slurry is as follows: 100 parts of water, 7.3 parts of graphene oxide, 2.4 parts of sodium alginate, 3.7 parts of zinc hyaluronate, 0.17 parts of vitamin B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com