Method for tungsten modification treatment of powder surface

A powder and modification technology, which is applied in the direction of gaseous chemical plating, coating, transportation and packaging, etc., can solve the problems of uniformity of mixing, uneven particle distribution and complicated process in the scale-up production process, and achieve the goal of overcoming fine The powder is difficult to fluidize, the reaction efficiency is high, and the coating integrity is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

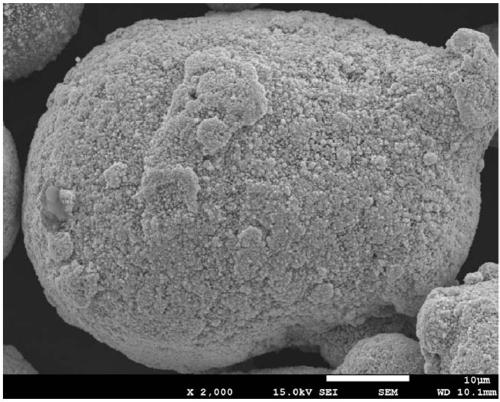

Embodiment 1

[0024] Aluminum powder with a particle size of 50 μm is placed in a fluidized bed reactor. The fluidized bed reactor is in a heating furnace. The reaction temperature of the heating furnace is 450 ° C. The fluidizing gas is a mixed gas of argon and hydrogen, and the volume percentage of hydrogen is is 20%, and the gas velocity is 0.08m / s. Load tungsten hexachloride vapor into the fluidized bed, and react with the powder fluidized section in the fluidized bed. The reaction time is 90min, and tungsten-coated aluminum is obtained. Composite powder, the tail gas enters the treatment system through the pipeline. The mass percent of tungsten coating is 8%.

Embodiment 2

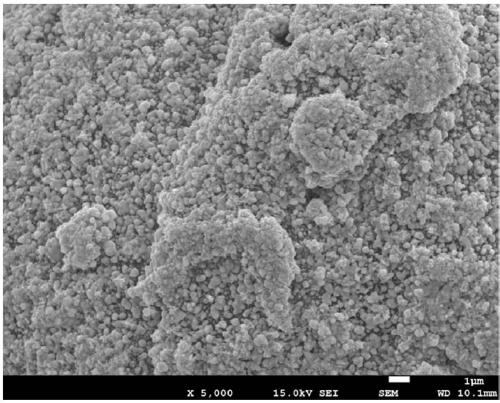

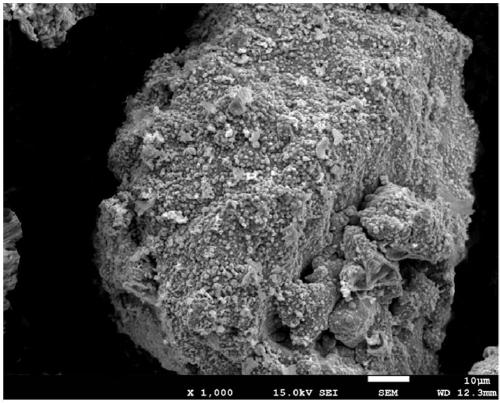

[0026] Put titanium powder with a particle size of 60 μm in a fluidized bed reactor, the fluidized bed reactor is in a heating furnace, the reaction temperature of the heating furnace is 520 ° C, the fluidizing gas is a mixed gas of argon and hydrogen, and the volume percentage of hydrogen is is 20%, and the gas velocity is 0.14m / s. Load tungsten hexafluoride vapor into the fluidized bed, and react with the powder fluidized section in the fluidized bed. The reaction time is 60min, and tungsten-coated titanium is obtained. Composite powder, the tail gas enters the treatment system through the pipeline. The mass percent of tungsten coating is 6%.

Embodiment 3

[0028] Put titanium carbide powder with a particle size of 220 μm in a fluidized bed reactor, the fluidized bed reactor is in a heating furnace, the reaction temperature of the heating furnace is 650 ° C, the fluidizing gas is a mixed gas of argon and hydrogen, and the hydrogen The volume percentage is 30%, and the gas velocity is 0.34m / s. The tungsten hexabromide vapor is loaded into the fluidized bed, and reacts with the powder fluidized section in the fluidized bed. The reaction time is 30min, and the tungsten cladding is obtained. Coated with titanium carbide composite powder, the exhaust gas enters the treatment system through the pipeline. The mass percent of tungsten coating is 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com