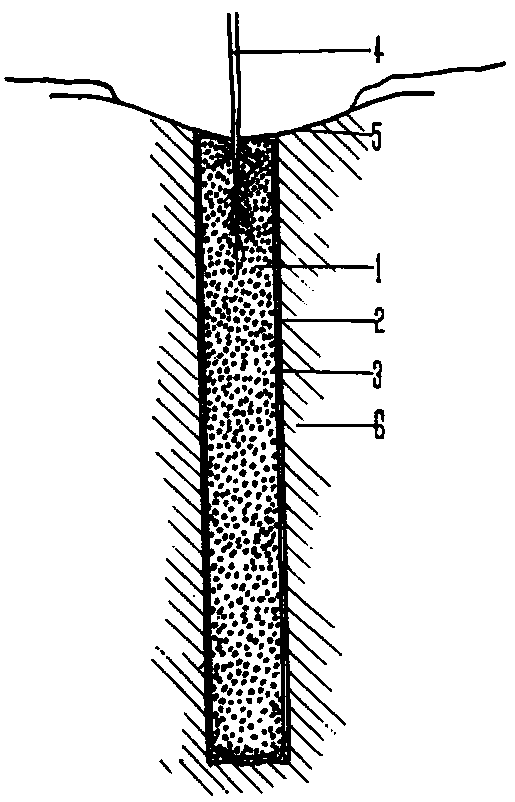

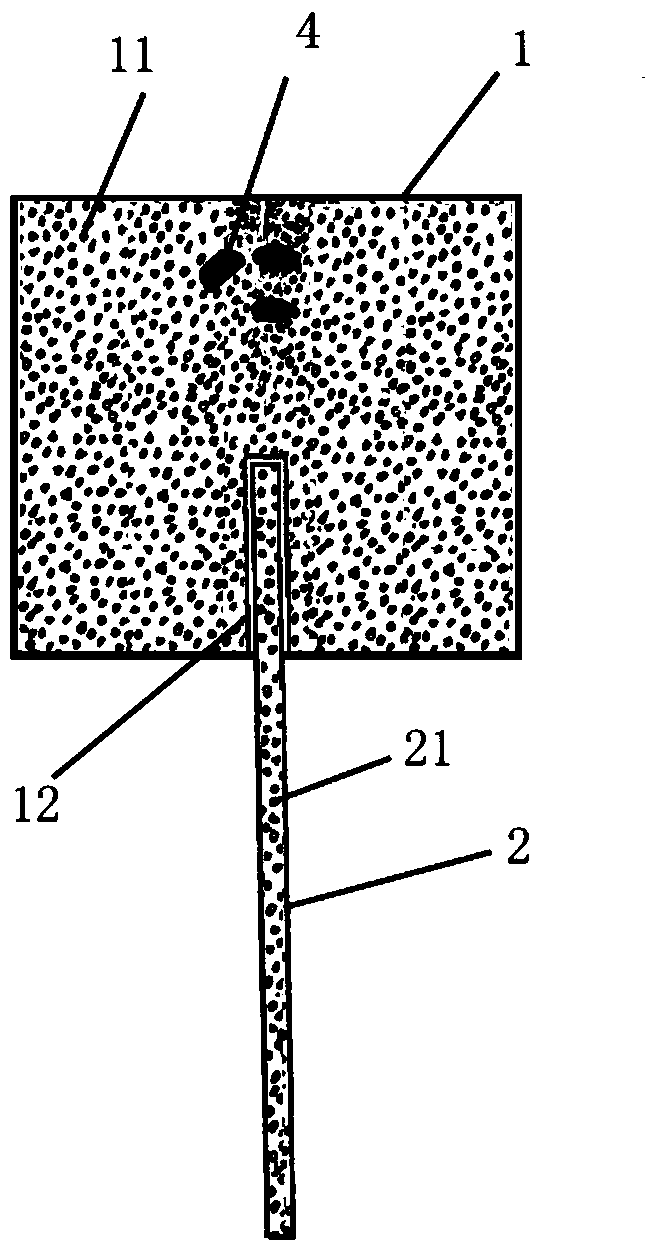

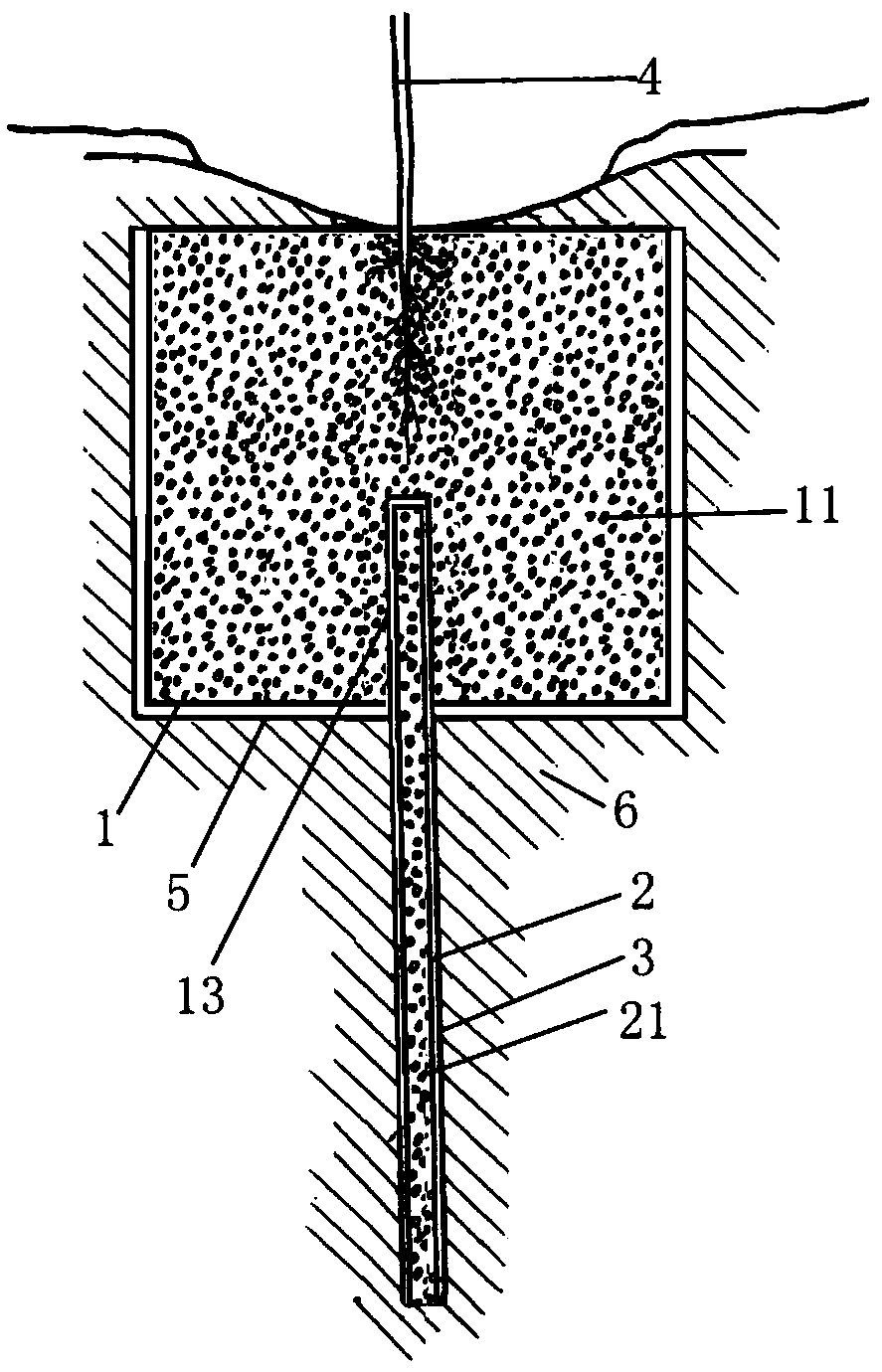

Desert greening soil module, and preparation and construction method thereof

A soil and desert technology, applied in the field of dryland greening, can solve the problems of not being easy to punch deep holes, increasing difficulty and cost, and not being easy to succeed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In an embodiment of the present invention, the soil (used soil), organic matter (compost, etc.), fertilizer, soil erosion preventive agent (polyacrylamide, etc.), soil microstate active agent, plus water, are formed by a pressure device Come. It can be made by hand or by machine.

[0071] The soil used is river accumulation soil (clay, silt) or on-site generated soil with 70-80% (the natural water content of the soil is 13-18.5%).

[0072] ②Organic materials are 7-15% of compost, bark compost, garbage compost, sawdust compost, crop shells, peat moss, etc.

[0073] ③What the fertilizer uses is a super-slow-acting fertilizer that is difficult to melt and lose with rainfall (N-nitrogen: P-phosphorus: K-potassium: Mg-magnesium=5-25%: 15-40%: 3-10%: 8- 20%) 3-10%. Because this fertilizer is soluble in acid base, it is especially beneficial to the growth and fixation of target plants.

[0074] ④Soil micro-state active agent, (40-60% aluminum oxide monohydrate, 2-10% ferrite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com