Protease and method for preparing low-cadmium rice polypeptide from protease

A protease, rice protein technology, applied in the field of biological enzymes, can solve the problems of inability to directly and effectively remove, increase production costs, increase exogenous additives and processing procedures, etc., achieve short reaction cycle, reduce industrial production costs, and enzymatic hydrolysis The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Protease strain screening

[0030] The soil of the rice planting area was used as the strain selection source.

[0031] Take 10g of the sample and add it to a conical flask filled with 90mL of sterile water, shake and mix for 10min, and then dilute with a 10-fold serial dilution method. Take 0.1mL of 10 -6 The diluted solution was added to protease-producing screening medium containing 100, 200, 400, 600, 800 mg / L cadmium, coated evenly, and placed upside down in a 30°C incubator. Using the medium without cadmium as a control, the single colony with a relatively large transparent circle obtained on each medium was obtained by streaking on a plate to obtain a pure culture.

[0032] The obtained high protease-producing strains were cultured to a bacterial concentration of 1.0×10 9 ~5.0×10 9 CFU / mL, centrifuge separately, add cadmium solution [CdCl 2 ·5H 2 O], shake treatment at 45°C for 4h, set 3 repetitions, and take the treatment of adding the same amount...

Embodiment 2

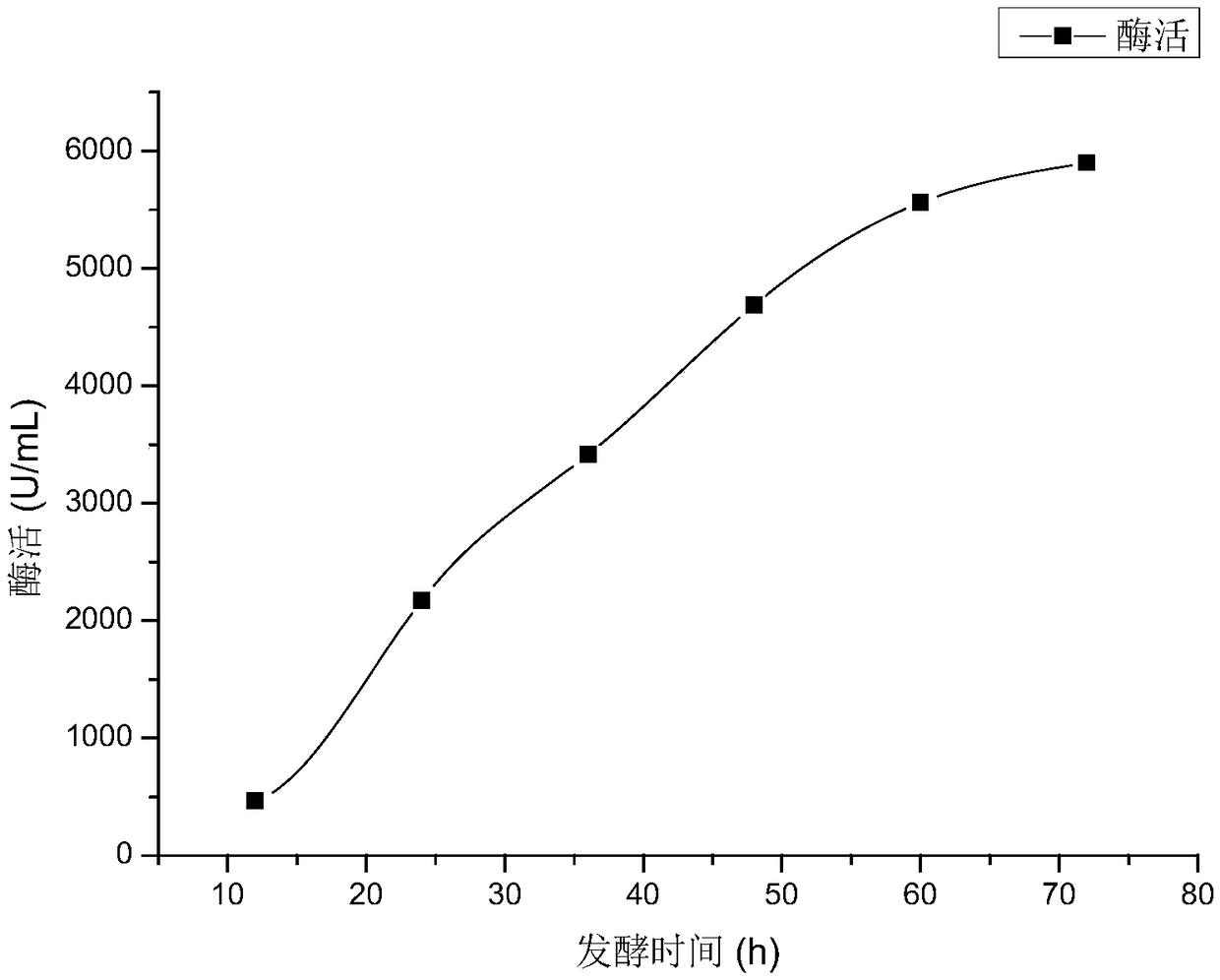

[0036] The preparation of embodiment 2 protease

[0037] The protease derived from Bacillus sp.D12 was codon-optimized to obtain the gene sequence shown in SEQ ID NO.2. The gene shown in SEQ ID NO.2 was synthesized, and the plasmid pMA5 was double digested with restriction endonucleases BamHI and NheI (primers were respectively F: GGATCCATGAAACATACAGATAAAGTTGGCC; R: GCTAGCGATGTAAGCAGCTTTGAAAGCTTGT, and agarose gel electrophoresis was used for gel cutting and recovery. Recover the product for ligation, system 10 μL: 1 μL double-cut vector, 4 μL double-cut target fragment, 5 μL Solution I ligase, ligate overnight at 16°C to obtain pMA5-neutrase; transform JM109 competent cells, pick single colony PCR verification, positive The recombinant was sequenced, and the alignment was correct to obtain recombinant Bacillus subtilis 168pMA5-neutrase (abbreviated as Bacillus subtilis NEU) expressing neutral protease.

[0038] Streak Bacillus subtilis NEU on a solid LB plate containing 50 μ...

Embodiment 3

[0040] The adsorption efficiency of embodiment 3 protease under different conditions

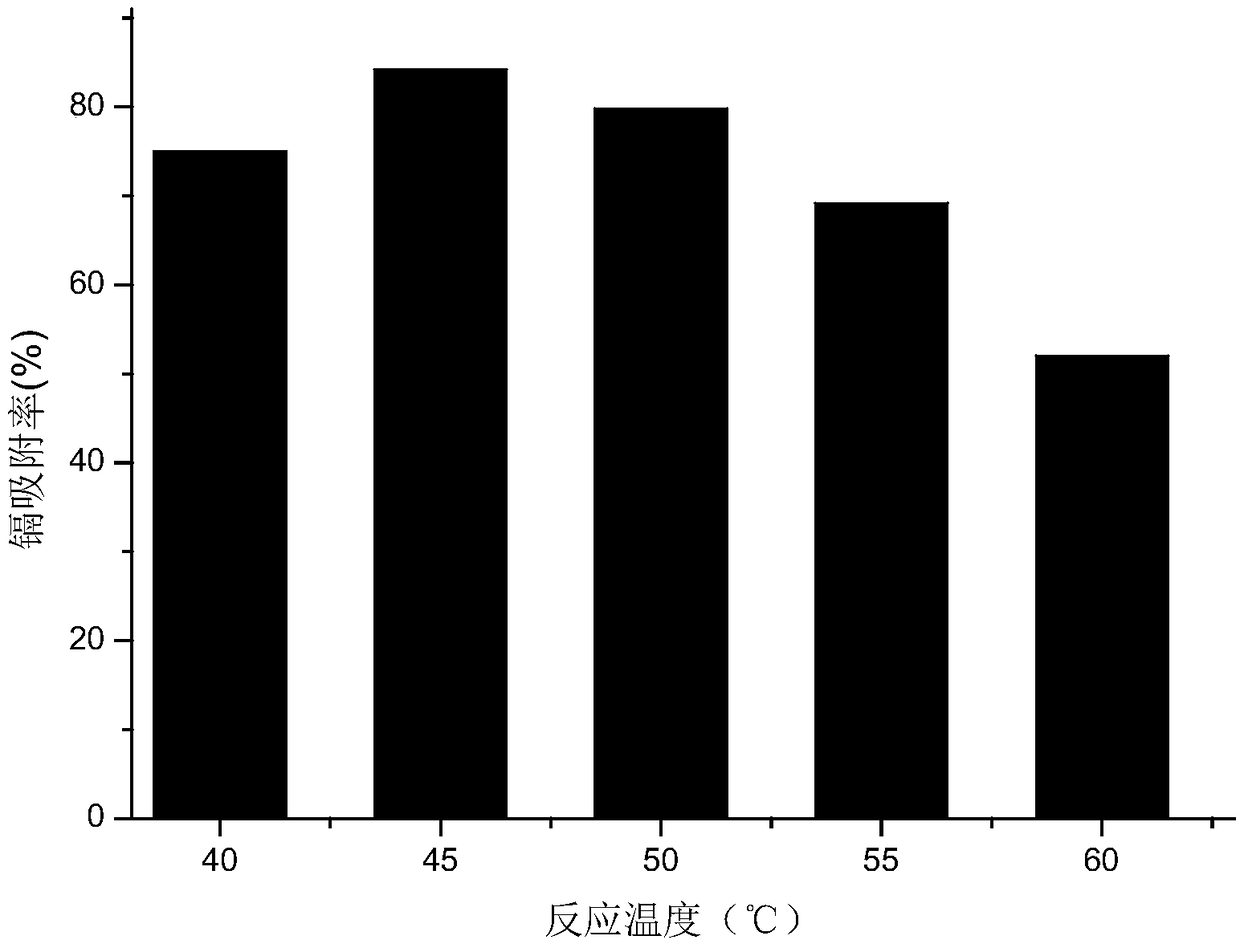

[0041] Prepare PBS buffer (pH 7.0) with a cadmium ion concentration of 10 mg / L, add the protease prepared in Example 2 with a final concentration of 1000 U / mL, react at 40-60° C. for 4 hours, and measure the cadmium adsorption rate. The results showed that the adsorption rate of cadmium was more than 75% at 40-50°C, and the adsorption rate could reach 84.2% when the reaction temperature was 45°C ( figure 2 ).

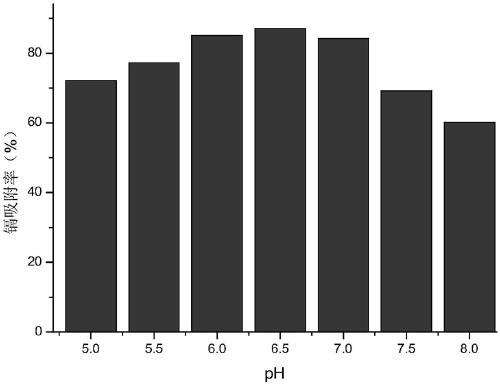

[0042]Prepare a reaction system with a pH of 5-8 according to the same steps above, add the protease prepared in Example 2 at a final concentration of 1000 U / mL, react at 45°C for 4 hours, and measure the cadmium adsorption rate. The results show that when the pH is 6-7, the adsorption rate of cadmium reaches more than 84.2%, and when the pH is 6.5, the adsorption rate can reach 84.2% ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com