Preparation method and application of dibenzylamine quaternary ammonium salt high-temperature-resistant acidizing corrosion inhibitor

一种酸化缓蚀剂、二苄胺的技术,应用在缓蚀剂材料领域,能够解决制备复杂、反应温度高等问题,达到制备方法简单、提高分散性、抑制腐蚀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

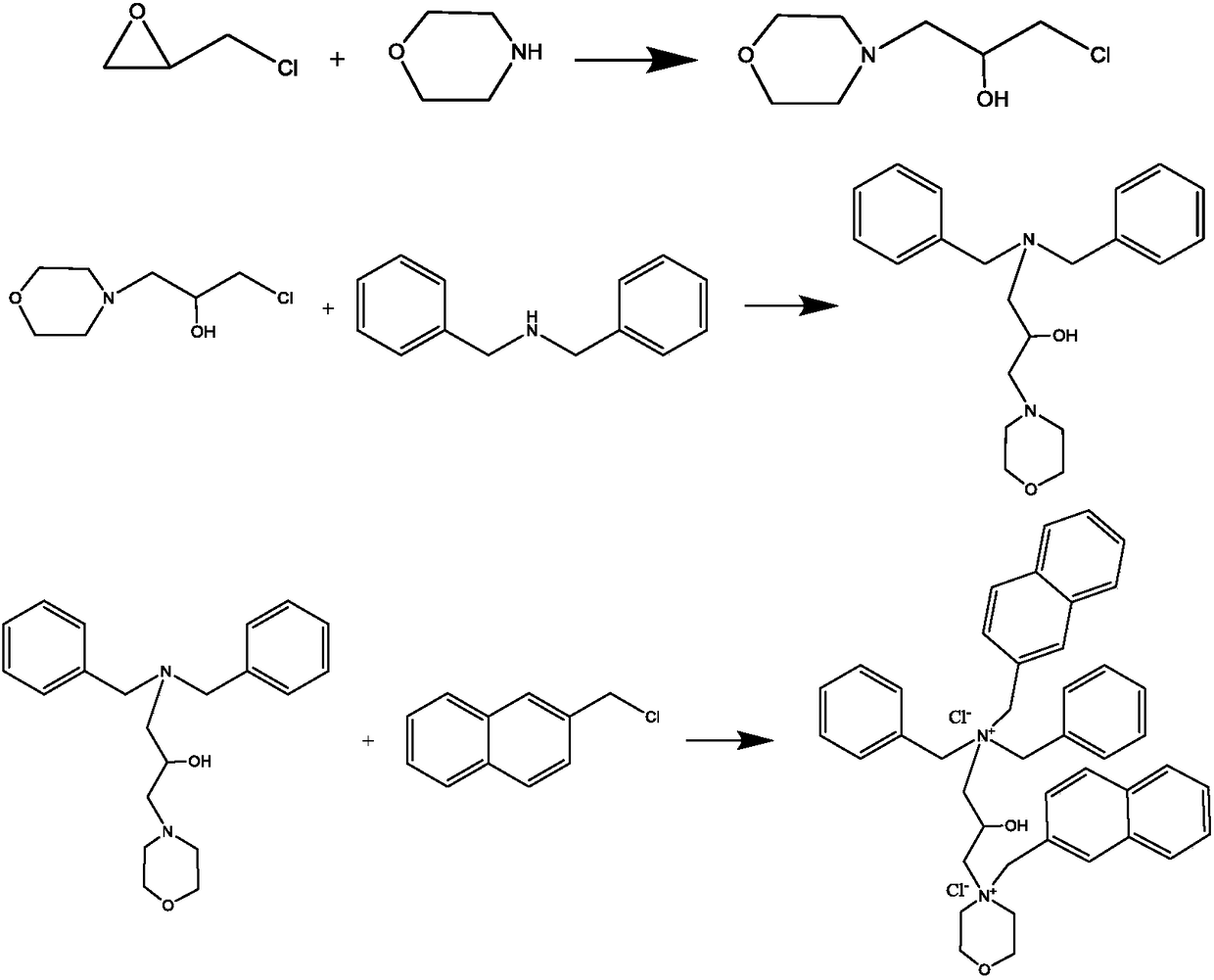

[0024] A preparation method of dibenzylamine quaternary ammonium salt high temperature acidification corrosion inhibitor, comprising the following steps:

[0025] (1) 8.71g of morpholine was added to a 250mL three-necked flask, while 80mL of absolute ethanol was added as a solvent and stirred evenly;

[0026] (2) Weigh 9.25g of epichlorohydrin, dissolve it in 30mL of absolute ethanol and stir evenly, slowly add dropwise into the morpholine solution, stir and react at room temperature for 14h, and obtain intermediate I after vacuum distillation;

[0027] (3) Weigh 1.79g of intermediate I and add it to a 250mL three-necked flask, add 90mL of absolute ethanol as a solvent and stir evenly, weigh 1.97g of dibenzylamine and dissolve it in 30mL of absolute ethanol and stir evenly, slowly drop Add 1.4g of potassium carbonate to the intermediate I solution, then raise the temperature to 80°C for reflux reaction for 14 hours, cool to room temperature after the reaction, filter, extract,...

Embodiment 2

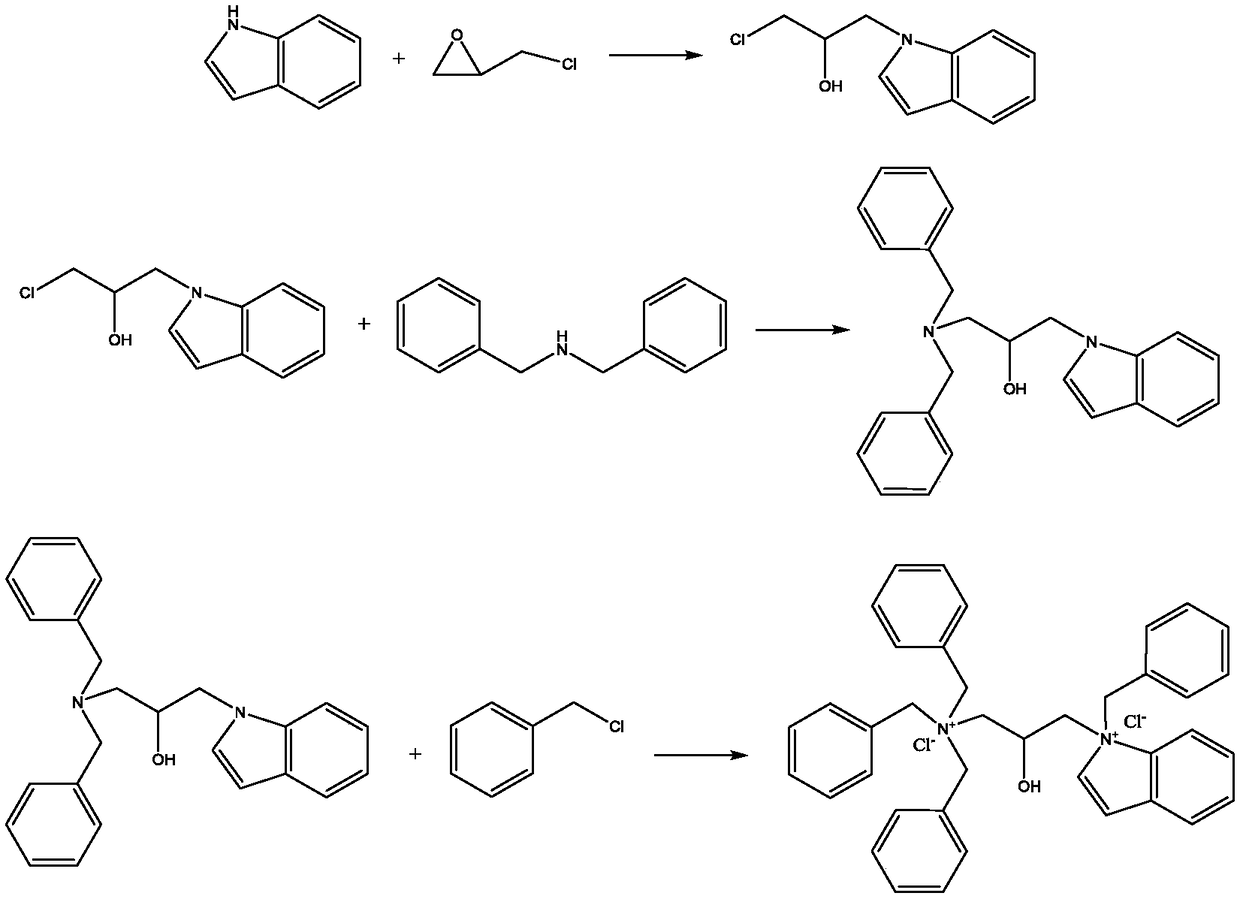

[0032] A preparation method of dibenzylamine quaternary ammonium salt high temperature acidification corrosion inhibitor, comprising the following steps:

[0033] (1) 5.59g of indole was added to a 250mL three-necked flask, while 70mL of acetone was added as a solvent and stirred evenly;

[0034] (2) Weigh 4.62g of epichlorohydrin, dissolve it in 30mL of acetone and stir evenly, slowly add it dropwise to the above-mentioned indole solution, stir and react at room temperature for 12h, and obtain intermediate I after vacuum distillation;

[0035] (3) Weigh 2.11g of intermediate I and add it to a 250mL three-necked flask. At the same time, add 90mL of acetonitrile as a solvent and stir evenly. Weigh 1.97g of dibenzylamine and dissolve it in 30mL of acetonitrile and stir evenly. Slowly add it dropwise to intermediate I solution, and added 1.2g of triethylamine, and then heated to 57 ° C reflux reaction for 15h, after the reaction was cooled to room temperature, filtered, extracted...

Embodiment 3

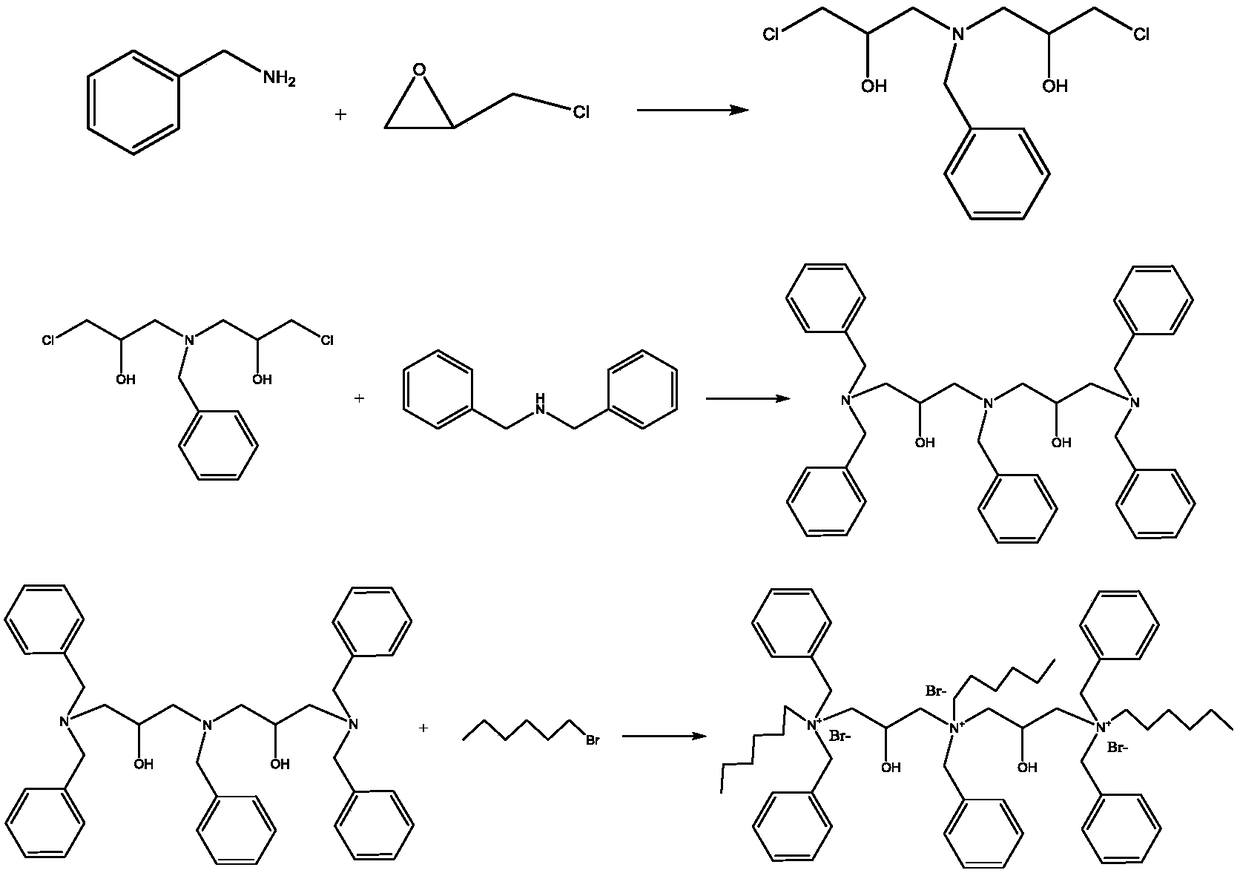

[0040] A preparation method of dibenzylamine quaternary ammonium salt high temperature acidification corrosion inhibitor, comprising the following steps:

[0041] (1) 10.82g of benzylamine was added into a 250mL three-necked flask, while 100mL of absolute ethanol was added as a solvent and stirred evenly;

[0042] (2) Weigh 9.25g of epichlorohydrin, dissolve it in 30mL of absolute ethanol and stir evenly, slowly add it dropwise to the above-mentioned benzylamine solution, stir and react at room temperature for 12h, and obtain intermediate I after vacuum distillation;

[0043] (3) Weigh 2.07g of intermediate I and add it to a 250mL three-neck flask, add 90mL of acetone as a solvent and stir evenly, weigh 1.97g of dibenzylamine and dissolve it in 30mL of acetone, stir evenly, and slowly add it dropwise to intermediate I solution, and added 0.7g of sodium hydroxide, and then heated to 60 ° C reflux reaction for 13h, after the reaction was cooled to room temperature, filtered, ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com