Separation method of azeotrope of dimethyl carbonate and methanol

A technology of dimethyl carbonate and a separation method, which is applied in the field of continuous extraction, rectification and separation of dimethyl carbonate and methanol, can solve the problems such as the inability of continuous operation of the extractant, and achieves stable continuous separation process, lower use threshold, and mutual solubility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

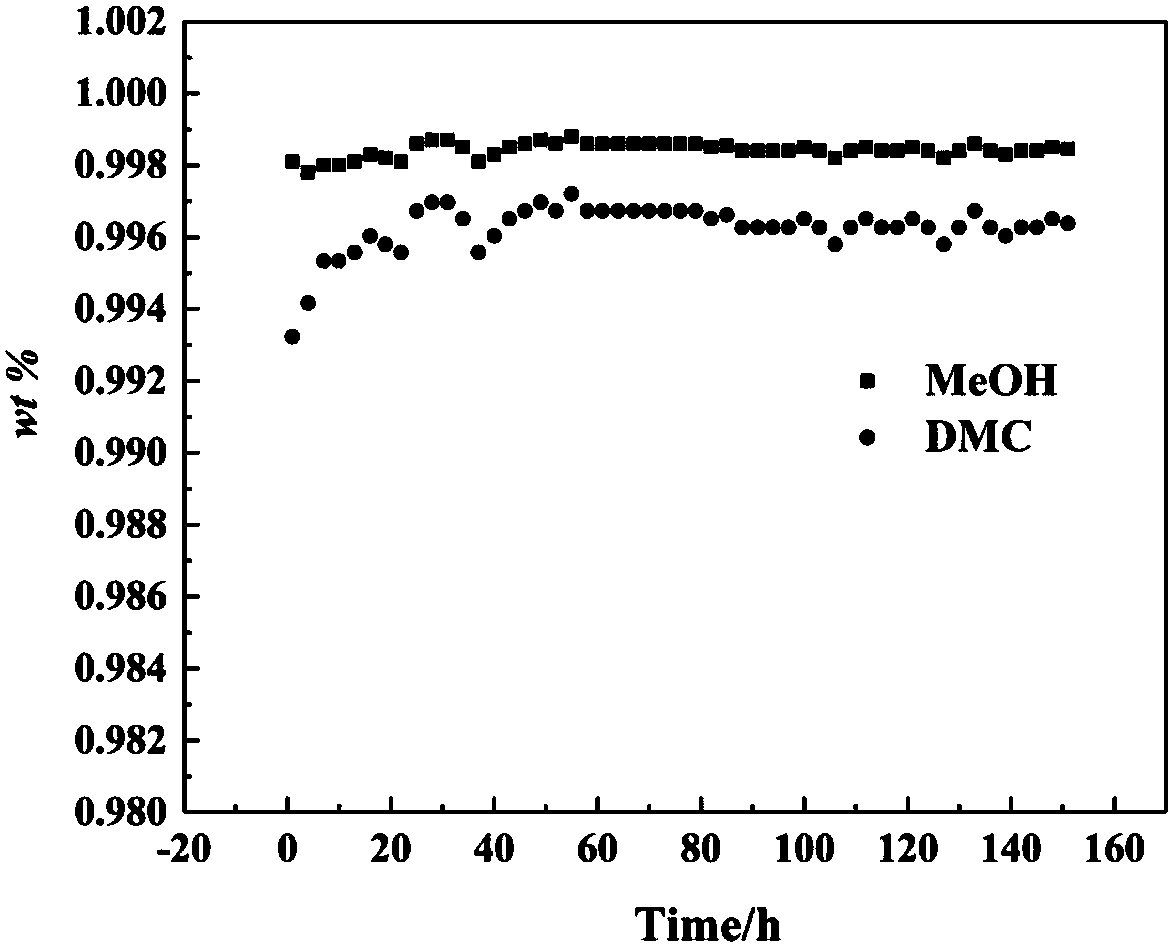

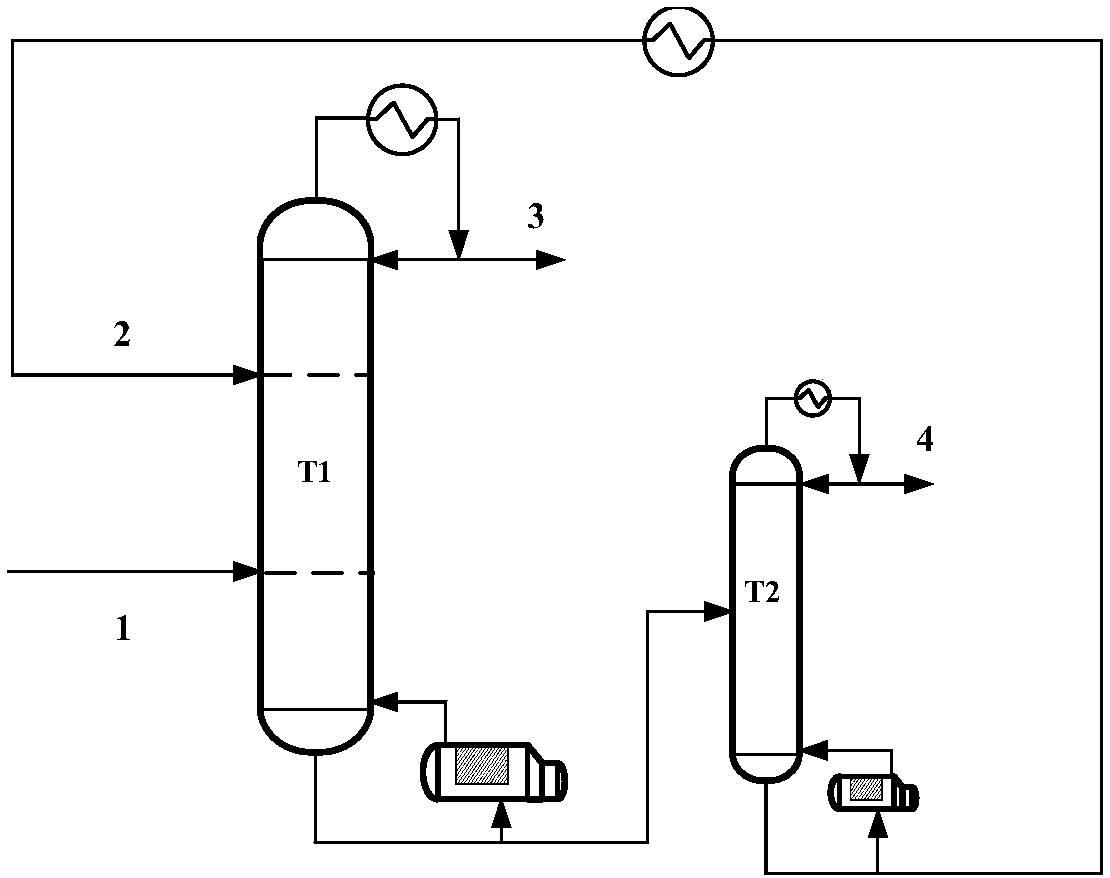

[0025] Such as figure 2 The extractive distillation process shown. The extractive distillation column has 30 theoretical plates (the number of plates is counted from top to bottom), and the mixed extractant contains 30wt% triethylene glycol dimethyl ether and 70wt% 1-ethyl-3-methylimidazole bistrifluoro Methanesulfonylimide salt ([emim][NTf 2 ]) add from the 4th tray, total flow is 8kg / h, the mixture of raw material dimethyl carbonate and methyl alcohol adds from the 27th tray, dimethyl carbonate content is 30wt%, methanol content is 70wt%, total The flow rate is 1kg / h, and the molar solvent ratio of the extractant to the raw material is 1.06 at this moment. The extractive distillation tower is operated under normal pressure, the top of the tower is fully condensed, the reflux ratio is 1.4, the output at the top of the tower is 0.7kg / h, 99.8wt% of methanol can be obtained, and the temperature of the top of the extractive distillation tower is 64°C. The temperature of the t...

Embodiment 2

[0027] Such as figure 2 The extractive distillation process shown. The extractive distillation column has 30 theoretical plates (the number of plates is counted from top to bottom), and the mixed extractant contains 30wt% triethylene glycol dimethyl ether and 70wt% 1-ethyl-3-methylimidazole bistrifluoro Methanesulfonylimide salt ([emim][NTf 2 ]) add from the 4th tray, total flow is 7kg / h, the mixture of raw material dimethyl carbonate and methyl alcohol adds from the 27th tray, dimethyl carbonate content is 30wt%, methanol content is 70wt%, total The flow rate is 1kg / h, and the molar solvent ratio of the extractant to the raw material is 0.93 at this moment. The extractive distillation tower operates under normal pressure, the top of the tower is fully condensed, the reflux ratio is 1.4, the output at the top of the tower is 0.7kg / h, 99.6wt% of methanol can be obtained, and the temperature of the top of the extractive distillation tower is 64°C. The temperature of the towe...

Embodiment 3

[0029] Such as figure 2 The extractive distillation process shown. The extractive distillation column has 30 theoretical plates (the number of plates is counted from top to bottom), and the mixed extractant contains 30wt% triethylene glycol dimethyl ether and 70wt% 1-ethyl-3-methylimidazole bistrifluoro Methanesulfonylimide salt ([emim][NTf 2 ]) add from the 4th tray, total flow is 10kg / h, the mixture of raw material dimethyl carbonate and methyl alcohol adds from the 27th tray, dimethyl carbonate content is 30wt%, methanol content is 70wt%, total The flow rate is 1kg / h, and the molar solvent ratio of the extractant to the raw material is 0.93 at this time. The extractive distillation tower operates under normal pressure, the top of the tower is fully condensed, the reflux ratio is 1.23, the output at the top of the tower is 0.7kg / h, 99.92wt% of methanol can be obtained, and the temperature of the top of the extractive distillation tower is 64°C. The temperature in the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com