Special carbon-base fertilizer for kiwi fruits, as well as preparation method and application thereof

A technology of kiwi fruit and carbon-based fertilizer, applied in the direction of application, nitrogen fertilizer, potassium fertilizer, etc., can solve the problems of affecting the absorption and utilization of nutrients by the root system, short fertilizer effect period, pollution, etc., to improve the physical and chemical properties of soil, increase yield and quality, and process steps simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

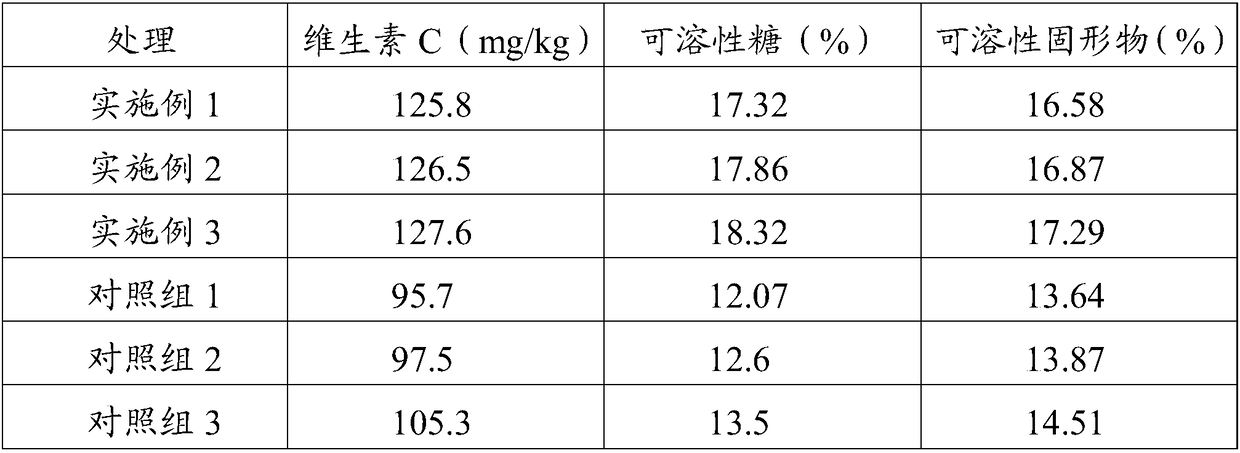

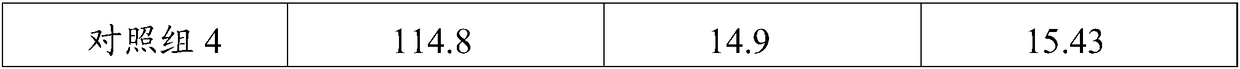

Examples

Embodiment 1

[0029] A. Crush flue-cured tobacco stalks, corn stalks, and rice stalks into 1-3cm fragments; mix them according to the mass percentage of 1:1:1, place them in a carbonization furnace, and keep the temperature at 125°C for 0.5 hours , dried; then heated up to 370°C, and pyrolyzed for 3 hours under airtight anaerobic conditions; the carbonized straw biochar was naturally cooled to room temperature, ground and passed through a 40-mesh sieve.

[0030] B. 30 parts of straw biochar, 8 parts of urea, 23 parts of urea phosphate, 5 parts of potassium chloride, 8 parts of potassium humate, 6 parts of boronite, 3 parts of magnesium sulfate, 1.8 parts of zinc sulfate, 0.5 parts of manganese sulfate , 0.7 parts of ammonium molybdate, 12 parts of bitter bark root powder, and 3 parts of neem seed powder. After mixing evenly, a special charcoal-based fertilizer for kiwi fruit is obtained.

[0031] The above-mentioned special charcoal-based fertilizer for kiwifruit is applied according to th...

Embodiment 2

[0033] A. Crush flue-cured tobacco stalks, corn stalks, and rice stalks into 1-3cm fragments; mix them according to the mass percentage of 1:0.8:0.4, place them in a carbonization furnace, and keep the temperature at 120°C for 0.5 hours , dried; then heated to 440°C, and pyrolyzed for 2.5 hours under airtight and anaerobic conditions; the carbonized straw biochar was naturally cooled to room temperature, ground and passed through a 45-mesh sieve.

[0034] B. 25 parts of straw biochar, 12 parts of urea, 21 parts of urea phosphate, 9 parts of potassium chloride, 5 parts of potassium humate, 5 parts of boronite, 6 parts of magnesium sulfate, 2 parts of zinc sulfate, and 1 part of manganese sulfate , 0.8 parts of ammonium molybdate, 8 parts of bitter bark root powder, and 4 parts of neem seed powder. After mixing evenly, a special charcoal-based fertilizer for kiwi fruit is obtained.

[0035] The above-mentioned kiwifruit special charcoal-based fertilizer is applied as the kiwifr...

Embodiment 3

[0037] A. Crush the flue-cured tobacco stalks, corn stalks, and rice stalks into 1-3cm pieces; mix the flue-cured tobacco stalks, corn stalks, and rice stalks in a mass percentage of 1:0:0, and place them in a carbonization furnace , keep the temperature at 130°C for 1 hour, and dry; then raise the temperature to 350°C, and pyrolyze for 3 hours under airtight and anaerobic conditions; naturally cool the carbonized straw biochar to room temperature, grind it and pass through 50 mesh screen.

[0038] B. 27 parts of straw biochar, 10 parts of urea, 25 parts of urea phosphate, 7 parts of potassium chloride, 7 parts of potassium humate, 3 parts of boronite, 5 parts of magnesium sulfate, 1 part of zinc sulfate, and 0.7 parts of manganese sulfate , 0.5 parts of ammonium molybdate, 10 parts of bitter bark root powder, and 5 parts of neem seed powder. After mixing evenly, a special charcoal-based fertilizer for kiwi fruit is obtained.

[0039] The above-mentioned special charcoal-bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com