Fermentation preparation and application of Chaetomium globosum dextranase

A technology of Chaetomium globosa and fermentation medium, which is applied in the direction of fermentation, glycosylase, enzyme, etc. It can solve the problems of no commercial dextranase product, low fermentation yield of dextranase, and inability to meet the needs of industrial preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Screening and identification of strains producing dextranase

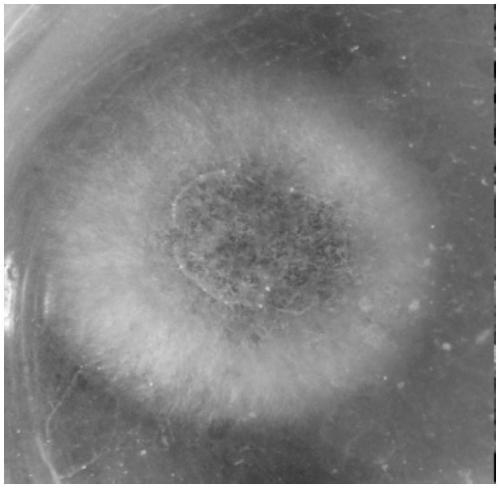

[0040] The soil samples were diluted with saline to 10 -5Spread PDA medium (potato 200g, glucose 20g, agar 15-20g), culture at 28°C for 5 days, obtain pure strains after preliminary screening, and re-screen the strains with blue dextran T2000 medium, and compare them through the transparent circle , to obtain a strain with higher enzyme production. According to electron microscope observation and 18S rDNA identification, the strain is Chaetomium globosa, and the nucleotide sequence of 18S rDNA is shown in SEQ ID NO.1. The photos of the colony characteristics of Chaetomium globosa are shown in figure 1 , SEM image see figure 2 .

Embodiment 2

[0041] Embodiment 2: Optimization of fermentation medium

[0042] Pick the mycelium of the bulbous hair shell and insert it into the seed medium, and use a rotary constant temperature shaker for cultivation, the rotation speed of the shaker is 220r / min, the cultivation temperature is 28°C, and cultivate for 60h to obtain the seed liquid; the composition of the seed medium For: glucose 5g / L, sodium chloride 0.5g / L, yeast powder 5g / L, dipotassium hydrogen phosphate 0.5g / L, magnesium sulfate 0.2g / L, after sterilization, add filter-sterilized kanamycin to The final concentration was 50 μg / mL.

[0043] The seed solution was inserted into a 250mL shake flask filled with 50mL fermentation medium at an inoculum size of 1%, and the fermentation temperature was 28°C.

[0044] Different types of dextran (dextran T20, T40, T2000) and different substances (glucose, maltose, lactose, soluble starch, corn dextrin, sucrose, fish meal peptone) were used as carbon sources; yeast extract, urea,...

Embodiment 3

[0046] Embodiment 3: the optimization of fermentation enzyme production condition

[0047] Pick the mycelium of the bulbous hair shell and insert it into the seed medium, and use a rotary constant temperature shaker for cultivation, the rotation speed of the shaker is 220r / min, the cultivation temperature is 28°C, and cultivate for 60h to obtain the seed liquid; the composition of the seed medium For: glucose 5g / L, sodium chloride 0.5g / L, yeast powder 5g / L, dipotassium hydrogen phosphate 0.5g / L, magnesium sulfate 0.2g / L, after sterilization, add filter-sterilized kanamycin to The final concentration was 50 μg / mL.

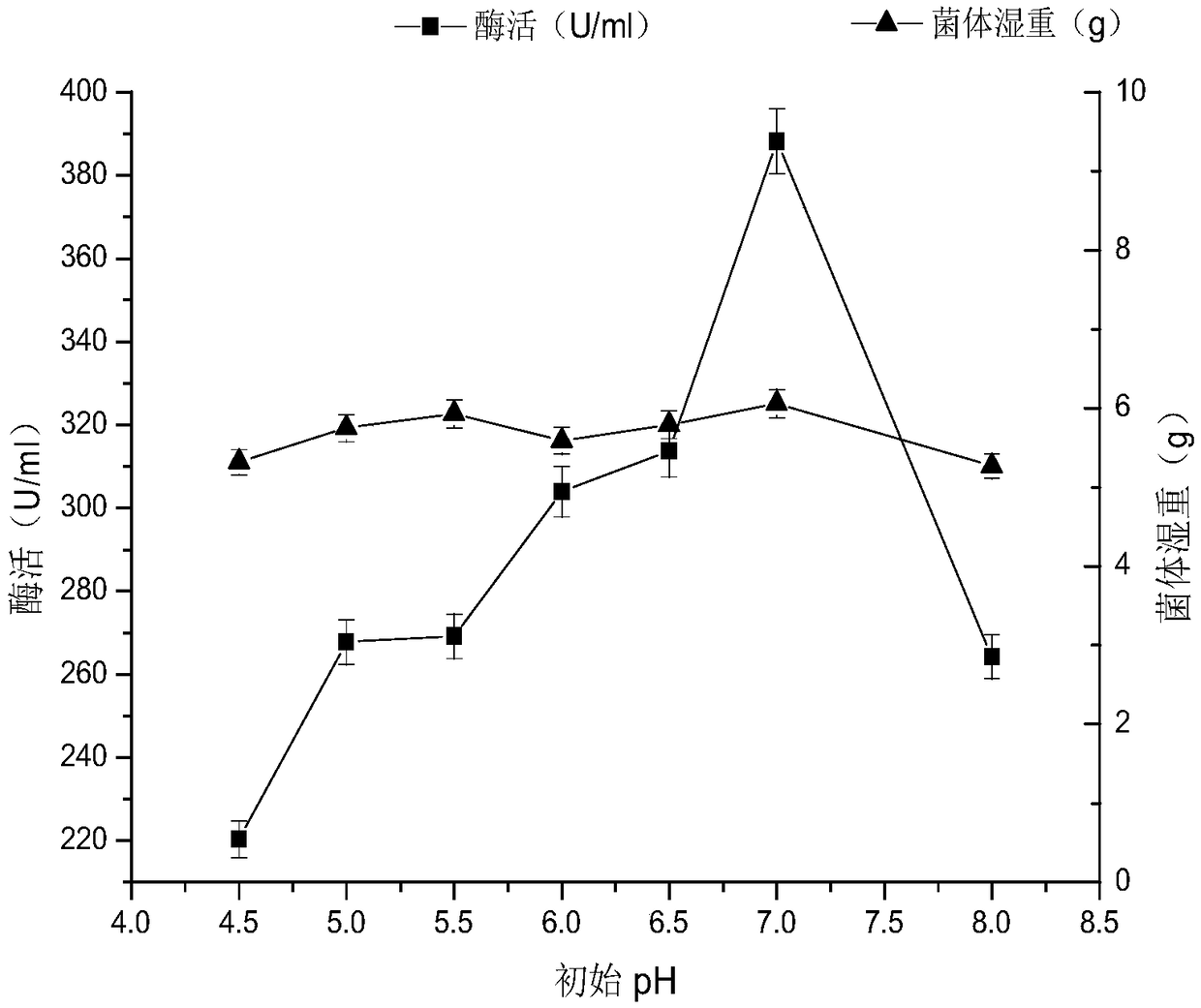

[0048] The seed solution was inserted into a 250mL shake flask with 50mL fermentation medium at an inoculation amount of 1%. The fermentation temperature was 28°C. The pH was set to 4.5, 5.0, 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, 9.0, respectively. The inoculum amounts were set to 1%, 2%, 3%, 4%, 5%, and 6%, respectively. The filling volume is set to 20mL, 30mL, 40mL, 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mw | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com