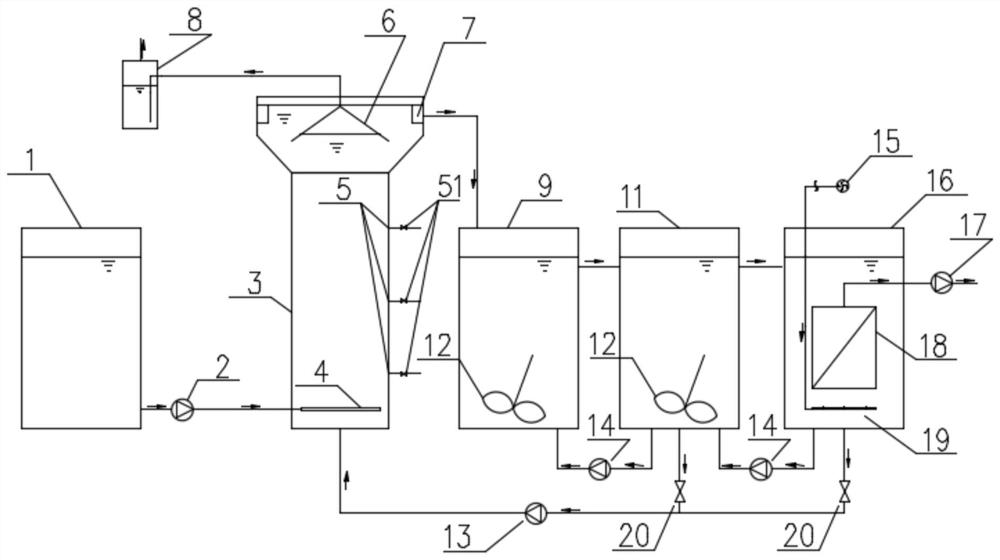

Membrane bioreactor and wastewater treatment method for simultaneous anammox and methane production

A membrane bioreactor, anaerobic methane production technology, applied in chemical instruments and methods, sustainable biological treatment, aerobic and anaerobic process treatment, etc., can solve the problems of unable to remove ammonium nitrogen, reduce, affect biological activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The microbial carrier is formed by mixing polysulfone particles and polyethylene glycol gel particles in a 3:2 manner, the pore size of the microbial carrier is 4-5 μm, and the porosity is 92%, and the dosage of the microbial carrier accounts for 1 / 5 of the volume of the anaerobic methanogenesis reactor 3.

[0041] The method for wastewater treatment using the synchronous anammox and methane-producing membrane bioreactors comprises the following steps:

[0042] Step S1: transport the sewage into the water inlet pool 1, and dilute to an organic concentration of 2200 mg(COD) / L~2500 mg(COD) / L;

[0043] Step S2: add the microbial carrier into the anaerobic methanogenesis reactor 3, start the water inlet pump 2, and transport the sewage in the water inlet pond 1 to the water distribution pipe 4 at the bottom of the anaerobic methanogenesis reactor 3, and spray from the water distribution hole. The discharged sewage forms an upward flow, which is fully contacted with the mic...

Embodiment 2

[0051] The microbial carrier is formed by mixing cellulose acetate particles, polyvinyl alcohol gel particles and polyurethane particles in a 2:2:1 manner. The pore size of the microbial carrier is 3-4 μm and the porosity is 90%. The dosing amount accounts for 1 / 4 of the volume of the anaerobic methanogenesis reactor 3 .

[0052] The method for wastewater treatment using the synchronous anammox and methane-producing membrane bioreactors comprises the following steps:

[0053] Step S1: the sewage is transported into the water inlet pool 1, and diluted to an organic concentration of 2400mg(COD) / L~2800mg(COD) / L;

[0054] Step S2: add the microbial carrier into the anaerobic methanogenesis reactor 3, start the water inlet pump 2, and transport the sewage in the water inlet pond 1 to the water distribution pipe 4 at the bottom of the anaerobic methanogenesis reactor 3, and spray from the water distribution hole. The discharged sewage forms an upward flow, which is fully contacted ...

Embodiment 3

[0062] The microbial carrier adopts polyvinylidene chloride particles, the pore size of the microbial carrier is 6-8 μm, the porosity is 88%, and the dosage of the microbial carrier accounts for 1 / 3 of the volume of the anaerobic methanogenesis reactor 3 .

[0063] The method for wastewater treatment using the synchronous anammox and methane-producing membrane bioreactors comprises the following steps:

[0064] Step S1: the sewage is transported into the water inlet pool 1, and diluted to an organic concentration of 2100mg(COD) / L~2400mg(COD) / L;

[0065] Step S2: add the microbial carrier into the anaerobic methanogenesis reactor 3, start the water inlet pump 2, and transport the sewage in the water inlet pond 1 to the water distribution pipe 4 at the bottom of the anaerobic methanogenesis reactor 3, and spray from the water distribution hole. The discharged sewage forms an upward flow, which is fully contacted with the microbial carrier until the sewage fills the anaerobic met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com