Light-fast and oxidation-resistant ink composition for writing pen

An ink composition and anti-oxidation technology, which is applied in inks, applications, household appliances, etc., can solve the problems of ink writing performance and chemical stability, can not show outstanding anti-oxidation performance, handwriting is easy to fade, etc., to improve thermal stability Performance and writing fluency, improved chemical stability and writing effect, improved UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

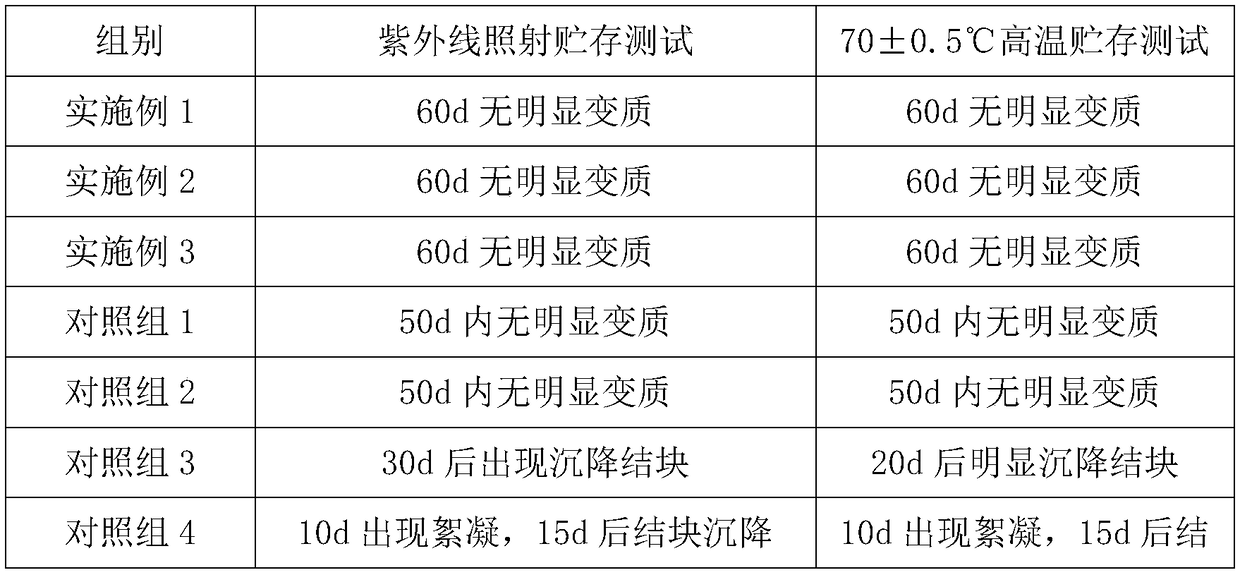

Examples

Embodiment 1

[0029] A light-resistant and anti-oxidation ink composition for writing pens. According to the mass percentage, the components of the ink composition include: 22% of colorant, 7.2% of bright pigment, 25% of water-soluble resin, 6.8% of thermoplastic polyurethane resin, and 2.2% of dextran , fucoidan 1.2%, polycarbodiimide 3%, organic solvent 11.5%, stabilizer 2.8%, corrosion inhibitor 0.3%, lubricant 1.5%, preservative 0.5%, and the balance is water.

[0030] In the present invention, the colorant is a mixture of dye Sudan Black B and azo pigment.

[0031] The stabilizer is a methanol solution of 1-butyl-3-methylimidazole and 2-hydroxyl-4-octyloxybenzophenone, and the content of 1-butyl-3-methylimidazole in the solution is 12.7%, 2 The content of -hydroxy-4-octyloxybenzophenone was 37.4%.

[0032] Bright pigments are glass flake pigments.

[0033] The water-soluble resin is an acrylate resin; the organic solvent is a mixture of propylene glycol, diethylene glycol and isoprop...

Embodiment 2

[0038] A light-resistant and anti-oxidation ink composition for a writing pen. According to the mass percentage, the components of the ink composition include: 25% of colorant, 8.6% of bright pigment, 35% of water-soluble resin, 15.7% of thermoplastic polyurethane resin, and 3.8% of dextran , fucoidan 1.5%, polycarbodiimide 4%, organic solvent 16.5%, stabilizer 3.6%, corrosion inhibitor 1.2%, lubricant 1.8%, preservative 1.5%, and the balance is water.

[0039] In this embodiment, the colorant is a mixture of inorganic pigments and organic pigments; the inorganic pigment is carbon black; the organic pigment is phthalocyanine pigment.

[0040] The stabilizer is a methanol solution of 1-butyl-3-methylimidazole and 2-hydroxyl-4-octyloxybenzophenone, and the content of 1-butyl-3-methylimidazole in the solution is 12.7%, 2 The content of -hydroxy-4-octyloxybenzophenone was 37.4%.

[0041] Bright pigments are aluminum flake pigments.

[0042] The water-soluble resin is polyester r...

Embodiment 3

[0047] A light-resistant and anti-oxidation ink composition for writing pens. According to the mass percentage, the components of the ink composition include: 23.5% of colorant, 8.1% of bright pigment, 30% of water-soluble resin, 10.5% of thermoplastic polyurethane resin, and 3.1% of dextran , fucoidan 1.3%, polycarbodiimide 3.6%, organic solvent 13.5%, stabilizer 3.2%, corrosion inhibitor 0.8%, lubricant 1.6%, preservative 0.9%, and the balance is water.

[0048] The colorant is a mixture of inorganic pigments and dyes; the proportion of inorganic pigments in the mixture is 70%.

[0049] The stabilizer is a methanol solution of 1-butyl-3-methylimidazole and 2-hydroxyl-4-octyloxybenzophenone, and the content of 1-butyl-3-methylimidazole in the solution is 12.7%, 2 The content of -hydroxy-4-octyloxybenzophenone was 37.4%.

[0050] The bright pigment is one or any mixture of glass flake pigments, aluminum flake pigments, phosphorescent pigments and fluorescent pigments.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com