Preparation method of hydrophobic, oleophobic and antibacterial coating for surface of textile material

A hydrophobic and oleophobic, fabric material technology, applied in textile material processing, liquid/gas/vapor textile processing, textile and papermaking, etc. Hydrophobic and oleophobic properties, strong self-protection ability, strong self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

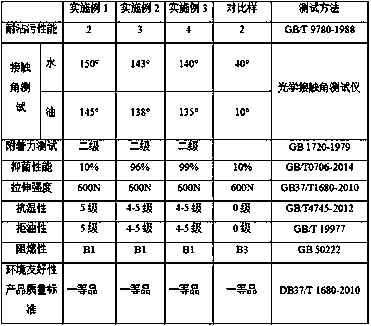

Examples

Embodiment 1

[0036] A method for preparing a hydrophobic, oleophobic and antibacterial coating on the surface of a fabric material, the selected base material is cloth, specifically comprising the following steps:

[0037]1. Pretreatment: The base material is ultrasonicated for 5 minutes at room temperature with a surface eluent. The composition of the surface eluent is: sodium bicarbonate (1.5%), ethanol (10%), fatty alcohol polyoxyethylene ether sodium sulfate ( 7.5 w / %), sodium dodecylbenzenesulfonate (8w / %), cocoic acid diethanolamide (0.6w / %), pure water (72.4%); then rinse the surface with ultrapure water, and then place Soak in strong alkaline electrolytic water for 1min. The components of the strong alkaline solution are: NaOH (0.5%), sodium bicarbonate (1%), sodium phosphate (2%), ethanol (6.5%), pure water (90%) . Take it out and rinse the surface with ultrapure water, then soak it in 40°C ethanol solution for 5 minutes, finally rinse it with ultrapure water, put it in an oven a...

Embodiment 2

[0041] A method for preparing a hydrophobic, oleophobic and antibacterial coating on the surface of a fabric material, the selected base material is cloth, specifically comprising the following steps:

[0042] 1. Pretreatment: The base material is ultrasonicated for 5 minutes at room temperature with a surface eluent. The composition of the surface eluent is: sodium bicarbonate (1.5%), ethanol (10%), fatty alcohol polyoxyethylene ether sodium sulfate ( 7.5 w / %), sodium dodecylbenzenesulfonate (8w / %), cocoic acid diethanolamide (0.6w / %), pure water (72.4%); then rinse the surface with ultrapure water, and then Soak in strong alkaline electrolyzed water for 1min. The components of the strong alkaline solution are: NaOH (0.5%), sodium bicarbonate (1%), sodium phosphate (2%), ethanol (6.5%), pure water (90% ). Take it out and rinse the surface with ultrapure water, then soak it in 40°C ethanol solution for 5 minutes, finally rinse it with ultrapure water, put it in an oven at 70°...

Embodiment 3

[0046] A method for preparing a hydrophobic, oleophobic and antibacterial coating on the surface of a fabric material, the selected base material is cloth, specifically comprising the following steps:

[0047] 1. Pretreatment: The base material is ultrasonicated for 5 minutes at room temperature with a surface eluent. The composition of the surface eluent is: sodium bicarbonate (1.5%), ethanol (10%), fatty alcohol polyoxyethylene ether sodium sulfate ( 7.5 w / %), sodium dodecylbenzenesulfonate (8w / %), cocoic acid diethanolamide (0.6w / %), pure water (72.4%); then rinse the surface with ultrapure water, and then Soak in strong alkaline electrolyzed water for 1min. The components of the strong alkaline solution are: NaOH (0.5%), sodium bicarbonate (1%), sodium phosphate (2%), ethanol (6.5%), pure water (90% ). Take it out and rinse the surface with ultrapure water, then soak it in 40°C ethanol solution for 5 minutes, finally rinse it with ultrapure water, put it in an oven at 70°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com