Plant plantation box for water treatment and plant replacing method thereof

A planting box and water treatment technology, applied in botany equipment and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as troublesome replacement of aquatic plants, and achieve resource saving, toughness and The effect of strength and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

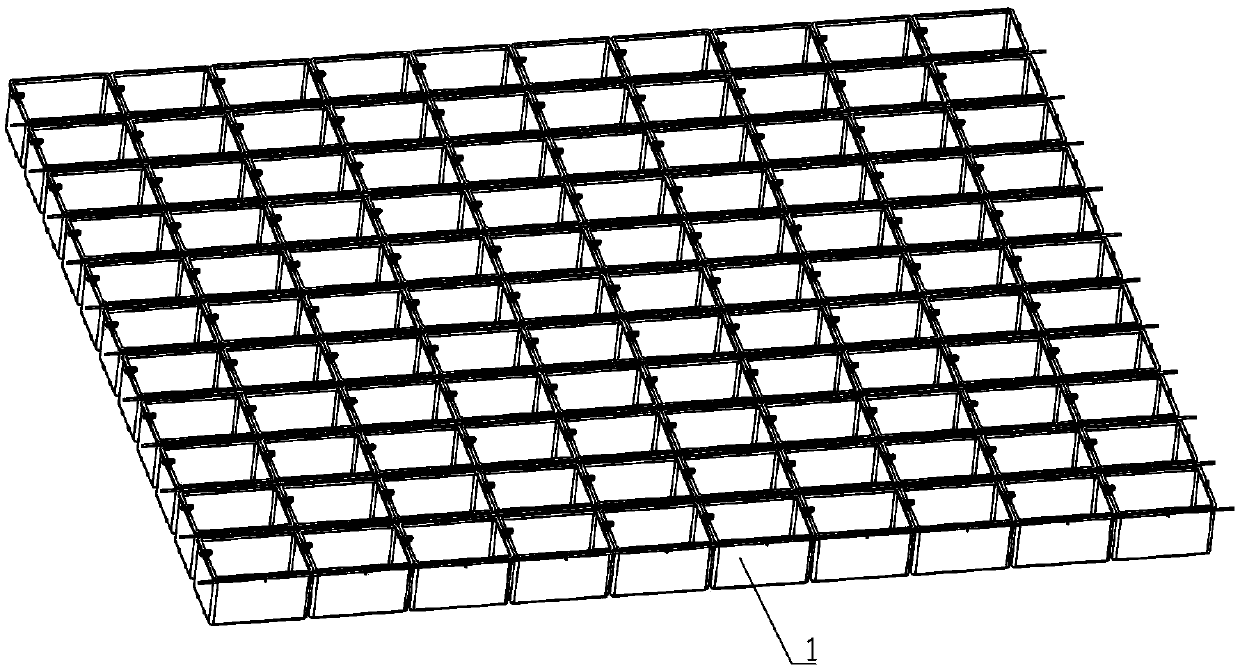

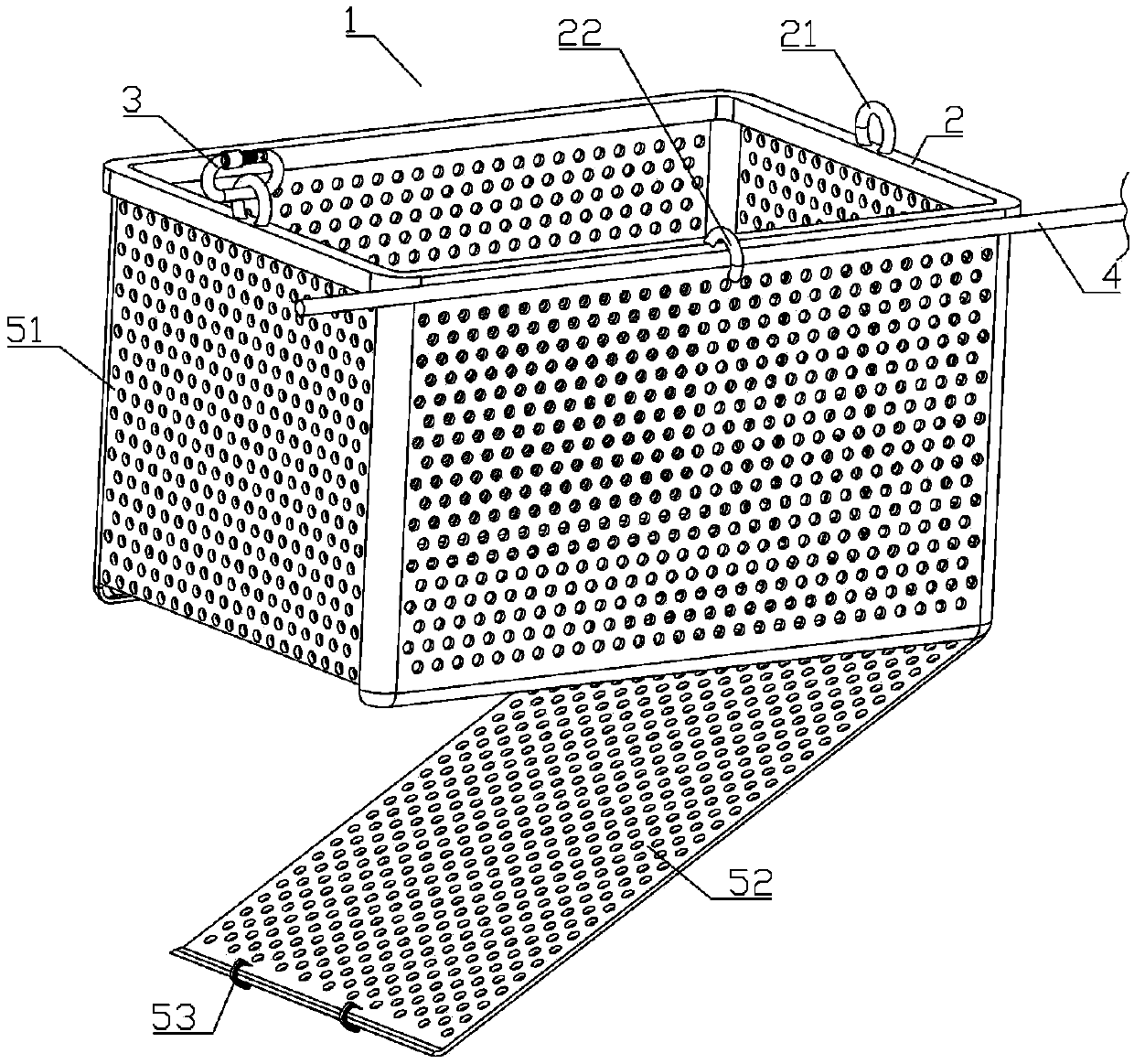

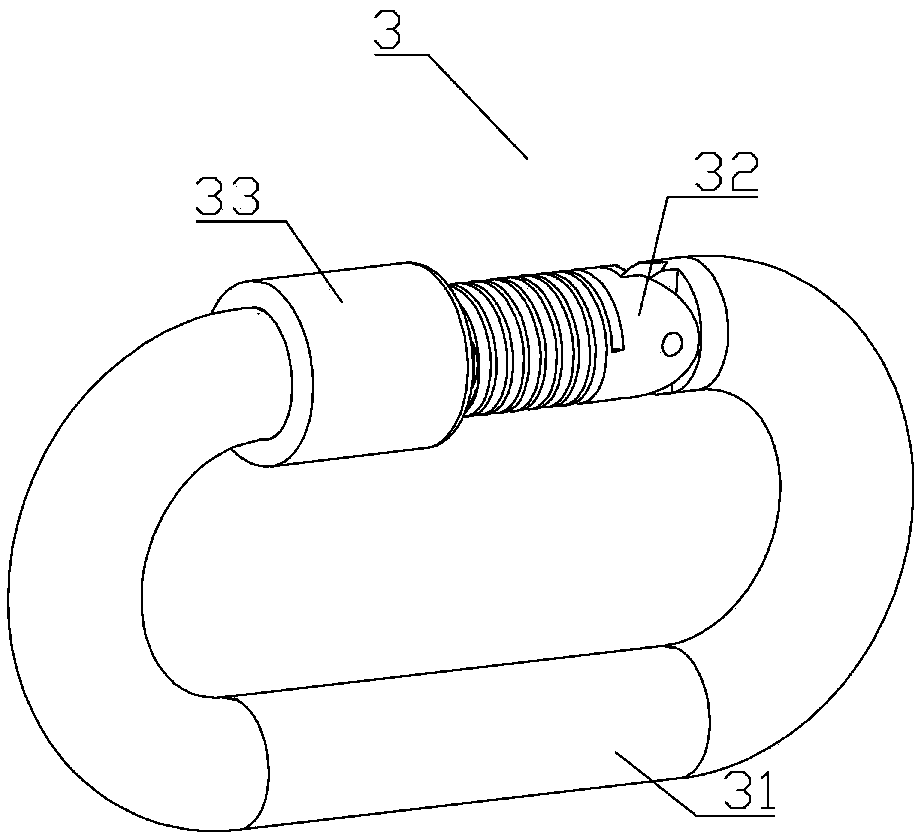

[0038] like Figure 1 ~ Figure 3 As shown, a plant planting box for water treatment of the present invention includes a planting group horizontally placed in the river, the planting group is composed of a plurality of boxes 1 arranged in a matrix, the box 1 includes a rectangular frame 2, a rectangular A ring 21 is respectively fixed on the left and right sides of the upper end surface of the frame 2. A buckle 3 is arranged between two adjacent boxes 1 in each row, and the buckle 3 is buckled on the circle of the two adjacent boxes 1 On the ring 21, a half-ring 22 is provided on the front end of the rectangular frame 2, and a cross bar 4 is provided on the front end of each row of the rectangular frame 2. 4, the lower end surface of the rectangular frame 2 is fixedly equipped with a coaming plate 51 for surrounding a rectangular frame, the coaming plate 51 lower end surface is provided with a base plate 52, and both the coaming plate 51 and the base plate 52 are provided with ...

Embodiment 2

[0042] Embodiment 2: Slow-release fertilizer box 1 Preparation 1

[0043] S1 short fiber with fat:

[0044] Phosphorus pentoxide is very easy to absorb moisture. It is necessary to pre-bake 200 parts by mass of phosphorus pentoxide in an oven at 100°C for 10 minutes, and weigh 400 parts by mass of sodium dihydrogen phosphate, 50 parts by mass of boric acid, 100 parts by mass of sodium carbonate, 100 parts by mass Parts by mass of potassium carbonate, 150 parts by mass of calcium carbonate, 100 parts by mass of magnesium carbonate pulverized, 50 parts by mass of silicon dioxide, mixed evenly with phosphorus pentoxide, put the mixture into a muffle furnace at 250°C for pre-calcination for 2 hours, add 50 parts by mass of diatomite and 50 parts by mass of chitosan are put into a muffle furnace at 500°C for melting and sintering to obtain phosphate glass, and the phosphate glass is cooled to 100°C, and 80 parts by mass of nitrogen fertilizer and 80 parts by mass of nitrogen fertil...

Embodiment 3

[0050] S1 short fiber with fat:

[0051] Phosphorus pentoxide is very easy to absorb moisture. It is necessary to pre-bake 150 parts by mass of phosphorus pentoxide in an oven at 100°C for 8 minutes, and weigh 450 parts by mass of sodium dihydrogen phosphate, 70 parts by mass of boric acid, 80 parts by mass of sodium carbonate, 80 parts by mass Parts by mass of potassium carbonate, 130 parts by mass of calcium carbonate, 130 parts by mass of magnesium carbonate pulverized, 30 parts by mass of silicon dioxide, mixed evenly with phosphorus pentoxide, put the mixture into a muffle furnace at 250°C for pre-calcination for 2 hours, add 40 parts by mass of diatomite and 40 parts by mass of chitosan are put into a muffle furnace at 550°C for melting and sintering to obtain phosphate glass, and the phosphate glass is cooled to 150°C, and 80 parts by mass of nitrogen fertilizer, 80 parts by mass of Phosphate fertilizer, 17 parts by mass of polyurethane, 10 parts by mass of rosin are us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com