A kind of calcium magnesium zinc liquid stabilizer and application thereof

A liquid stabilizer, calcium-magnesium-zinc technology, applied in the field of calcium-magnesium-zinc liquid stabilizers, can solve the problems of large difference in refractive index of silicone oil substances, affecting product opacity, affecting product quality, etc., to achieve good synergistic performance and excellent transparency , Durable processability and the effect of peeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

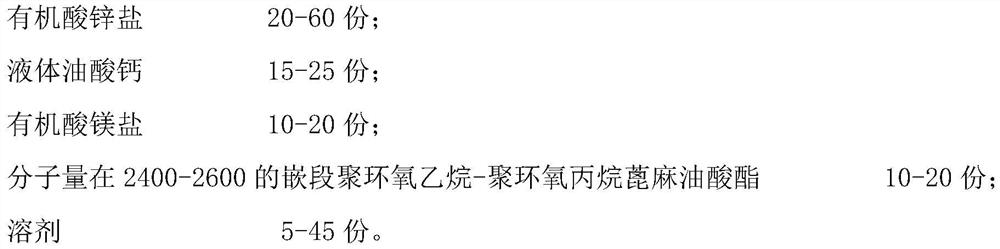

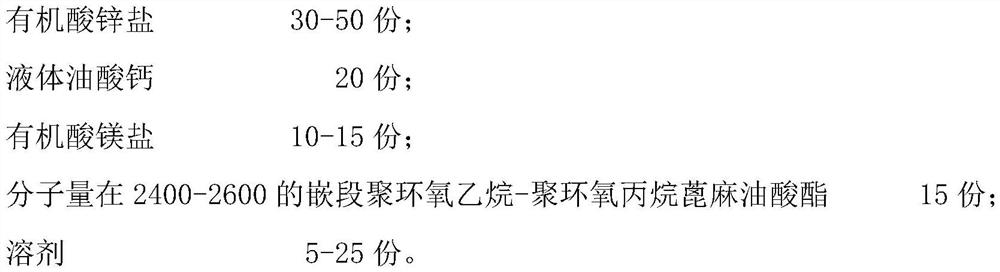

Method used

Image

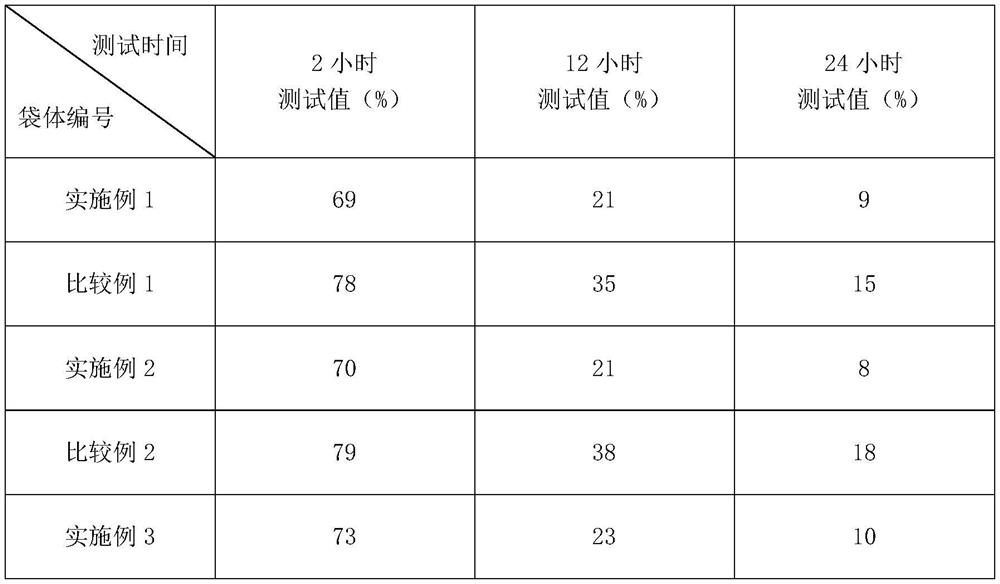

Examples

Embodiment 1

[0027] Zinc isooctanoate 350g, zinc 4-tert-butylbenzoate 250g, liquid calcium oleate 300g, magnesium laurate 300g, diethylene glycol monobutyl ether 100g, kerosene 400g, block polyethylene oxide-polypropylene oxide castor oil Ester 300g.

[0028] After mixing the above formula into a uniform stabilizer, let it stand for use.

[0029] According to the composition ratio of PVC resin: PVC (SG-1000) 100kg, dioctyl terephthalate 35kg, epoxy soybean oil (B-22) 10kg, antifogging agent AF 0.5kg, stabilizer 3kg. Put the above formula into a high-speed mixer for high-speed thermal mixing, and the end temperature of thermal mixing is 125°C. Enter the cold mix and set aside.

[0030] The cooled powder is subjected to single-screw granulation, the temperature of the granulation die head is 168°C, and the detection value during melting and compaction is not greater than 12.5pa. After granulation, pass through a vibrating sieve and collect.

[0031] The collected pellets are put into a s...

Embodiment 2

[0037] The raw material ratio of the stabilizer: 60g of zinc 4-tert-butylbenzoate, 30g of liquid calcium oleate, 30g of magnesium stearate, 30g of block polyethylene oxide-polypropylene oxide ricinoleate, Octyl ester 20g, diethylene glycol monobutyl ether 5g, liquid paraffin 25g.

Embodiment 3

[0041] Raw material ratio of stabilizer: 35g of zinc oleate, 25g of zinc 4-tert-butylbenzoate, 30g of liquid calcium oleate, 30g of magnesium stearate, 30g of block polyethylene oxide-polypropylene oxide ricinoleate, Dioctyl terephthalate 20g, diethylene glycol monobutyl ether 5g, liquid paraffin 25g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com