Farmyard manure granules and preparation method thereof

A technology of farmyard manure granules and cake fertilizers, which is applied in the preparation of organic fertilizers, nitrogen fertilizers, and potassium fertilizers. It can solve the problems of polluting the environment, easily causing root diseases and insect pests, etc., and achieves the effects of long fertilizer effect period, quick effect, and good absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

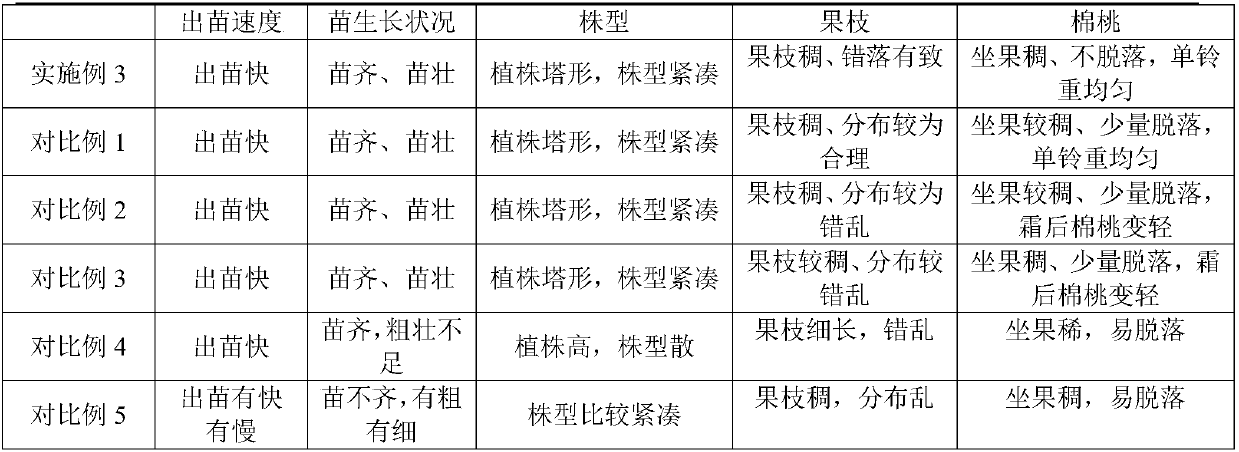

Examples

Embodiment 1

[0037] A farmyard manure granule, comprising the following raw materials in parts by weight: 50 parts of human feces, 30 parts of pig manure, 10 parts of cake fertilizer, 10 parts of soybean straw; 10 parts of urea-formaldehyde, 10 parts of superphosphate, and 15 parts of modified vermiculite , 15 parts of humic acid, 2 parts of poppy shell powder, 6 parts of biological fermentation agent, 8 parts of alum, 2 parts of basil, 2 parts of sodium fluorosilicate; 30 parts of auxiliary materials.

[0038] The preparation method of described modified vermiculite is as follows:

[0039] a. Take a certain amount of lecithin, stir it at room temperature to make it completely dissolved in 20m L absolute ethanol,

[0040] b. Take 1.0g of vermiculite and 180m L of deionized water and add them to the above-mentioned lecithin solution. The relationship between the amount of lecithin added and the vermiculite is: n PC:mCEC=0.214-3.42mmol g-1;

[0041] c. Use 0.1M nitric acid solution to adjus...

Embodiment 2

[0055] A farmyard manure granule, comprising the following raw materials in parts by weight: 60 parts of human excrement, 40 parts of pig manure, 20 parts of cake fertilizer, 20 parts of soybean straw; 15 parts of urea-formaldehyde, 15 parts of superphosphate, and 20 parts of modified vermiculite , 20 parts of humic acid, 3 parts of poppy husk powder, 10 parts of biological fermentation agent, 10 parts of alum, 3 parts of basil, 3 parts of sodium fluorosilicate and 50 parts of auxiliary materials.

[0056] See Example 1 for the preparation method of the modified vermiculite.

[0057] The poppy husk powder is crushed and ground into powder, 5 times by weight of starch and 0.1 times by weight of iron powder are added.

[0058] The effective viable bacteria of the biological fermentation bacterial agent is a mixed bacterial agent of Bacillus pumilus, Pseudomonas stutzeri and Rhodococcus, and the number of effective bacteria is more than 1 billion / g.

[0059] The composition and ...

Embodiment 3

[0068] A farmyard manure granule, comprising the following raw materials in parts by weight: 55 parts of human excrement, 35 parts of pig manure, 15 parts of cake fertilizer, 15 parts of soybean straw; 12 parts of urea-formaldehyde, 12 parts of superphosphate, and 17 parts of modified vermiculite , 18 parts of humic acid, 2.5 parts of poppy shell powder, 8 parts of biological fermentation agent, 9 parts of alum, 2.5 parts of basil, 2.5 parts of sodium fluorosilicate and 40 parts of auxiliary materials.

[0069] The preparation method of described modified vermiculite sees embodiment 1;

[0070] The poppy husk powder is crushed and ground into powder, and 4 times by weight of starch and 0.07 times by weight of iron powder are added.

[0071] The effective viable bacteria of the biological fermentation bacterial agent is a mixed bacterial agent of Bacillus pumilus, Pseudomonas stutzeri and Rhodococcus, and the number of effective bacteria is more than 1 billion / g.

[0072] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com