High-efficiency flame-retardant coating with fire warning and self-repair functions, its preparation method and application

A technology of fire early warning and flame retardant coatings, which is applied in the direction of fire retardant coatings, hyaluronic acid coatings, chitin polysaccharide coatings, etc., can solve the problems of low sensitivity of fire warning systems and flammability of light materials, and achieve excellent thermal stability and Barrier performance, excellent char formation performance, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

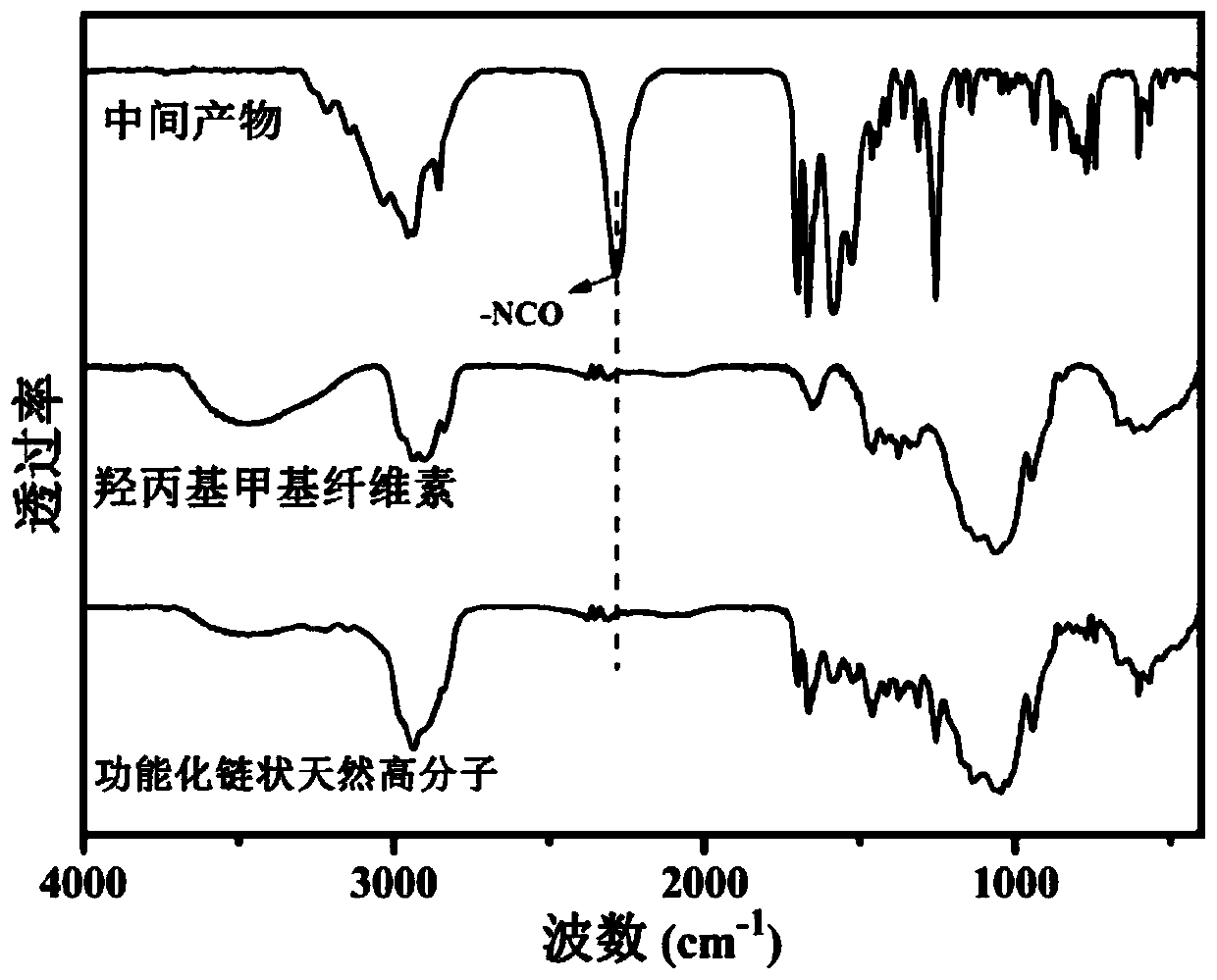

[0036] 1) Synthesis of intermediates: at 100°C, add 4g of 2-amino-4-methylpyrimidine and 30g of dimethylbiphenyl diisocyanate into a 150mL four-necked flask, and make 2-amino- 4-methylpyrimidine is well dispersed. Then react for 12h under the protection of nitrogen. After the reaction was finished, the mixed solution was left to cool, and 50 mL of n-pentane was added to precipitate the reaction product. The product was isolated by suction filtration, soaked and washed with n-pentane and suction filtered again, and the washing process was repeated 4 times. The intermediate product was obtained after drying in an oven at 80 °C for 8 h.

[0037] 2) Synthesis of functional chain-like natural polymers: Add 3 g of hydroxypropyl methylcellulose, 1 g of the intermediate synthesized in step 1) and 100 mL of ethylene glycol into a 250 mL four-neck flask, and stir them ultrasonically for 30 min to fully disperse them. Add 0.03g of cobalt octoate and protect it with nitrogen, and raise...

Embodiment 2

[0045] The difference between this embodiment and Example 1 is: in step 1), 2-amino-4-methylpyrimidine is replaced by 2-methyl-4-aminopyrimidine, and 30g dimethyl biphenyl diisocyanate is replaced by 40g 1 , 6-hexamethylene diisocyanate, the mechanical stirring time was shortened to 20min, the reaction temperature was reduced to 90°C, and the reaction time was shortened to 10h. The solvent used to precipitate the product and wash it was changed to isopropanol, and the drying time was reduced to 12 hours. The vertical combustion, fire warning and self-healing test results are shown in Table 1, Table 2 and Table 3, and the relevant test methods are the same as in Example 1.

Embodiment 3

[0047] The difference between this example and Example 1 is that in step 1), 4g of 2-amino-4-methylpyrimidine is replaced by 3g of 2-amino-4,6-dimethylpyrimidine, and 30g of dimethyl biphenyl diisocyanate Replaced with 12g of 4,4-diisocyanate dicyclohexylmethane, the reaction was raised to 130°C, and the reaction time was extended to 24h. The solvent used to precipitate and wash the product was changed to n-hexane, and the amount used for precipitation was changed to 100 mL. The drying temperature was increased to 100°C, and the drying time was increased to 20h. The vertical combustion, fire warning and self-healing test results are shown in Table 1, Table 2 and Table 3, and the relevant test methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com