Fully biodegradable foaming seedling tray suitable for mechanical transplanting and preparation method thereof

An all-biological, seedling tray technology, applied in the field of agricultural seedling raising, can solve the problems of high cost of biodegradable seedling trays, low notch tear force value, non-degradable materials, etc., to reduce seedling replenishment operations, reduce density, and facilitate mechanical cutting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

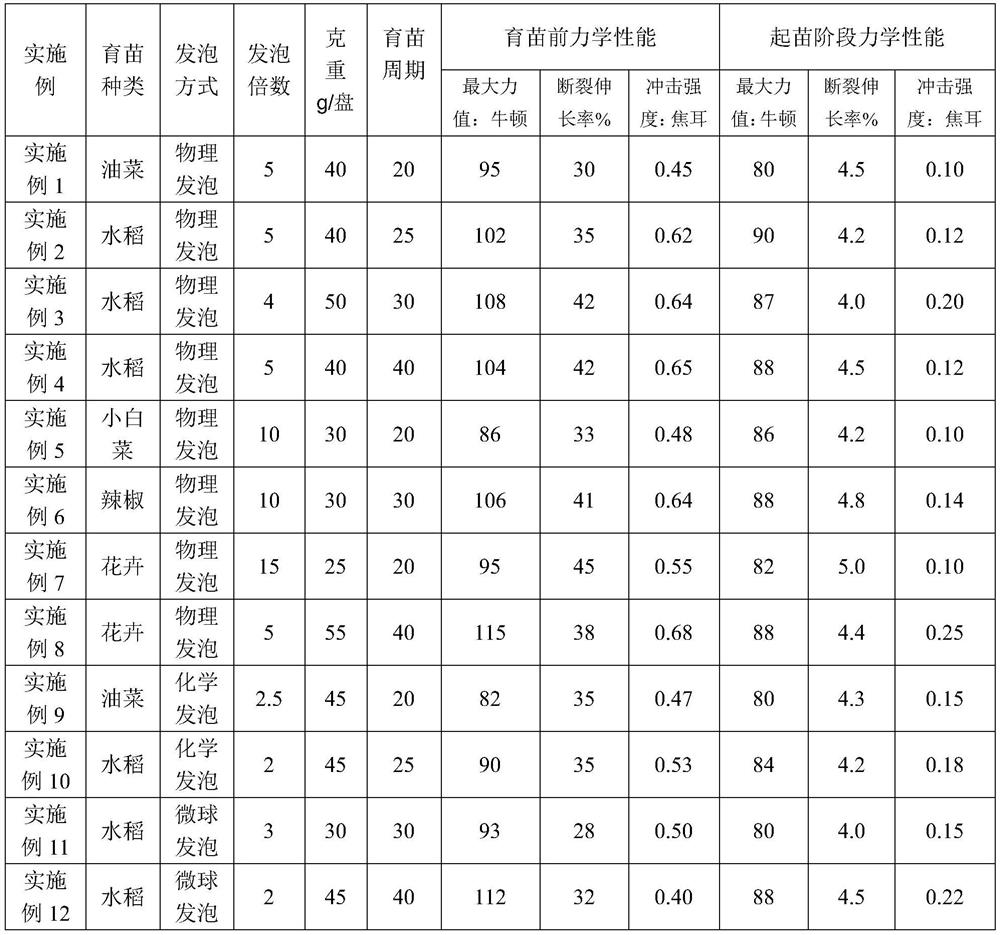

Examples

preparation example Construction

[0041] The preparation method of the fully biodegradable foaming seedling tray suitable for mechanical transplanting according to the second aspect of the present invention is used to prepare the fully biodegradable foaming seedling tray suitable for mechanical transplanting according to the first aspect of the present invention, which The method comprises the steps of: mixing raw materials, extruding and granulating, preparing foam sheets, and forming foam seedling raising trays.

[0042] In the preparation method of the biodegradable foaming seedling raising tray according to the present invention, each step can be: (1) mixing raw materials: take the whole bio-based degradable resin, bio-based filler and auxiliary agent by weight, and mix them with a high-speed mixer , to obtain the compound, the rotating speed of the high-speed mixer is 500-1200r / min, and the mixing time is 10-25 minutes; (2) Extrusion granulation: adopt twin-screw extruder to the mixing described in step (1...

Embodiment 1

[0059] 40 parts of polylactic acid, 20 parts of polybutylene adipate / terephthalate, 20 parts of corn starch, 10 parts of bamboo fiber, 0.2 parts of 5000 mesh talcum powder, 2 parts of MAH grafted PLA, 1.5 parts of monoglyceride , add the above raw materials into the high mixer and mix for 10 minutes at 800r / min to make them evenly mixed, extrude and granulate through twin-screw at 165°C and 200r / min, and put the prepared particles at a temperature of 80°C and a vacuum degree of less than 100pa Dry in a vacuum dryer for 6 hours to make the water content <50ppm, and then extrude and foam through a two-stage foaming unit to obtain a foamed sheet. The first-stage screw temperature is controlled at 165-175°C, and the second-stage temperature is controlled at 145-125°C ℃, the foaming agent is 98% butane, the foaming agent addition pressure is controlled at 10Mpa, the extrusion pressure is controlled at 10-15Mpa, the screw speed is controlled at 50r / min, the thickness of the obtained ...

Embodiment 2

[0062] 45 parts of polylactic acid, 25 parts of polybutylene adipate / terephthalate, 10 parts of corn starch, 10 parts of bamboo fiber, 0.2 parts of 5000 mesh talc powder, 2 parts of MAH grafted PLA, 1 part of monoglyceride , add the above raw materials into the high mixer at 800r / min and mix for 10 minutes to make them evenly mixed, then extrude and granulate through twin-screw at 200r / min, and put the prepared granules in a vacuum dryer with a temperature of 80°C and a vacuum degree of less than 100pa Medium drying for 6 hours to make the water content <50ppm, and then extruded and foamed by a two-stage foaming unit to obtain a foamed sheet. The foaming agent is 98% butane, the blowing agent addition pressure is controlled at 10Mpa, the extrusion pressure is controlled at 10-15Mpa, the screw speed is set at 50r / min, the sheet thickness obtained is 1mm, and the expansion ratio is 5, The foamed sheet is formed by a positive and negative pressure forming machine. The heating tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com