Method for improving dye adsorption capacity of latex particle extract of latex wastewater

A latex particle and adsorption capacity technology, which is applied in the field of improving the adsorption capacity of latex particles extracted from water-based latex wastewater to cationic dyes, can solve the problems of difficult treatment, heavy secondary pollution, heavy industrial waste pollution, etc., and achieve effective treatment, Effect of increasing B/C value and reducing pollution load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

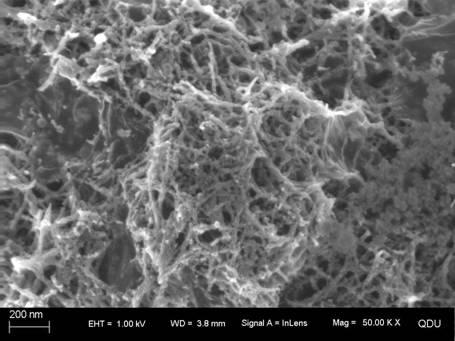

Image

Examples

Embodiment 1

[0025] S1: Filter the mixed latex production wastewater to remove suspended matter, then concentrate it with an ultrafiltration membrane, and the concentration factor is 10 times;

[0026] S2: Add aluminum sulfate to the concentrated solution, stir and react for 20 minutes, until an insoluble latex particle extract is formed;

[0027] S3: Press filter and dehydrate the latex particle extract to a water content of 80%, and then pulverize the extract;

[0028] S4: Adding NaHCO with a mass ratio of 1:1 to the extract (by dry weight) to the latex particle extract 3 , stir quickly to make the latex particle extract thin into a paste and dissolve NaHCO 3 , ultrasonic treatment at 60°C for 30 min;

[0029] S5: Vacuum drying at 90°C, so that part of the latex is softened, bonded and expanded to form a porous latex particle extract;

[0030] S6: The dried porous latex particle extract was placed in N 2 Heat treatment at a heating rate of 5°C / min under protection, and then rapidly r...

Embodiment 2

[0036] S1: Filter the mixed latex production wastewater to remove suspended matter, then concentrate it with an ultrafiltration membrane, and the concentration factor is 10 times;

[0037] S2: Add ferric chloride to the concentrated solution, stir and react for 20 minutes, until an insoluble latex particle extract is formed;

[0038] S3: Press filter and dehydrate the latex particle extract to a water content of 80%, and then pulverize the extract;

[0039] S4: Adding NaHCO with a mass ratio of 1: 1.5 to the extract (by dry weight) to the latex particle extract 3, stir quickly to make the latex particle extract thin into a paste and dissolve NaHCO 3 , ultrasonic treatment at 60°C for 40 min;

[0040] S5: Vacuum drying at 80°C to soften and cohere part of the latex to form a porous latex particle extract;

[0041] S6: The dried porous latex particle extract was placed in N 2 Under protection, heat treatment at a heating rate of 10°C / min, and then rapidly raise the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equilibrium adsorption capacity | aaaaa | aaaaa |

| Equilibrium adsorption capacity | aaaaa | aaaaa |

| Equilibrium adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com