Method for preparing Bi-Mn doping-modified TiO2/diatomite composite material by sol-gel method with ultrasonic wave assistance

A sol-gel method and composite material technology, applied in the field of sewage treatment, can solve the problems of low stability and easy deactivation of pure nano-titanium dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

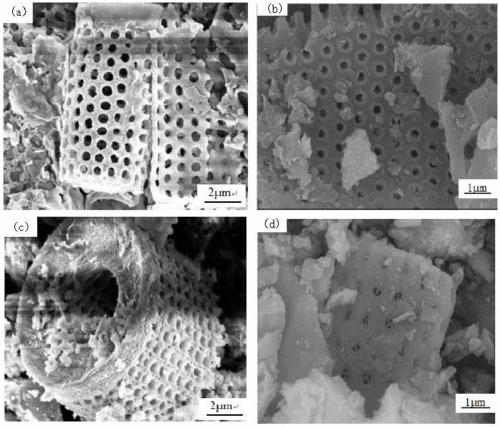

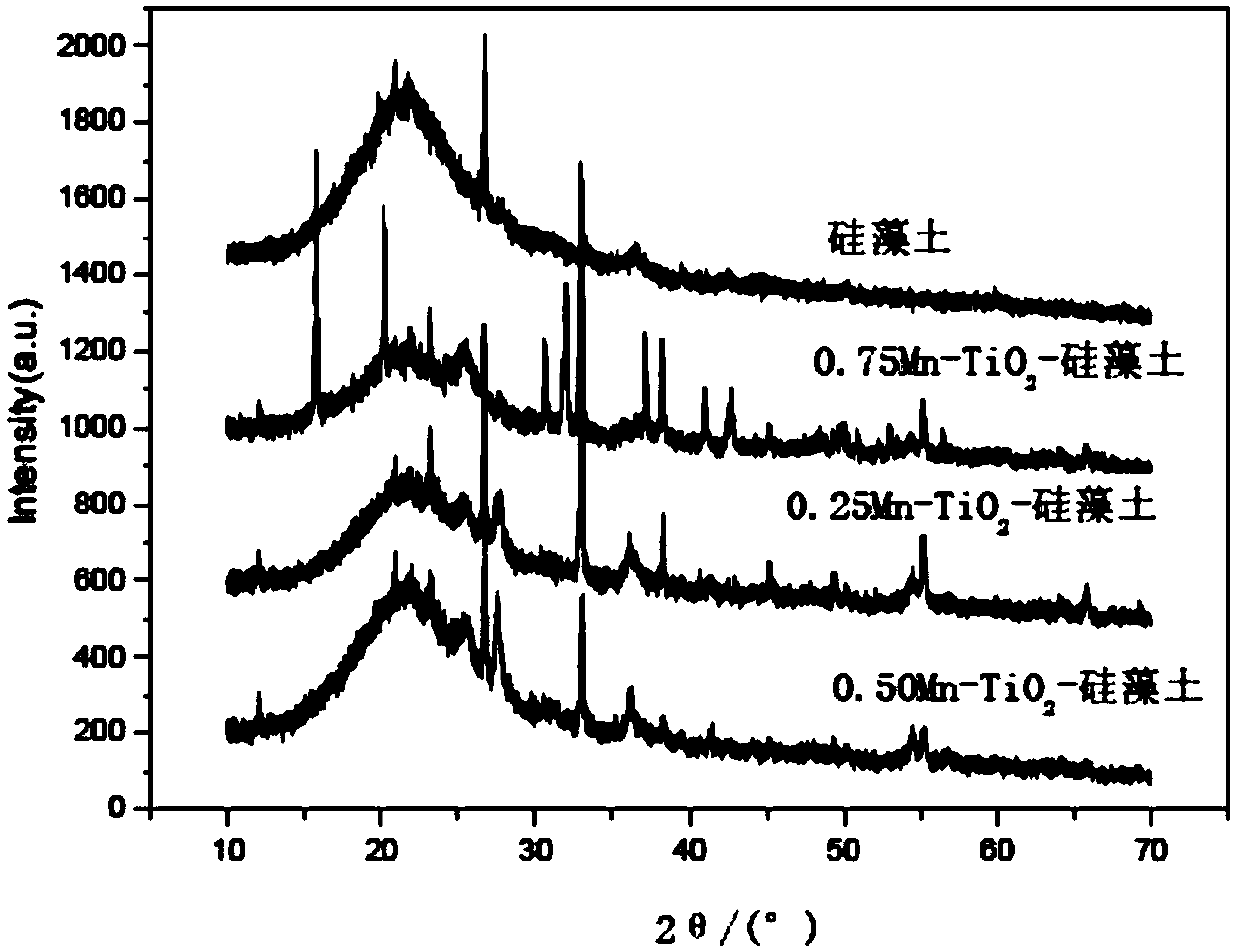

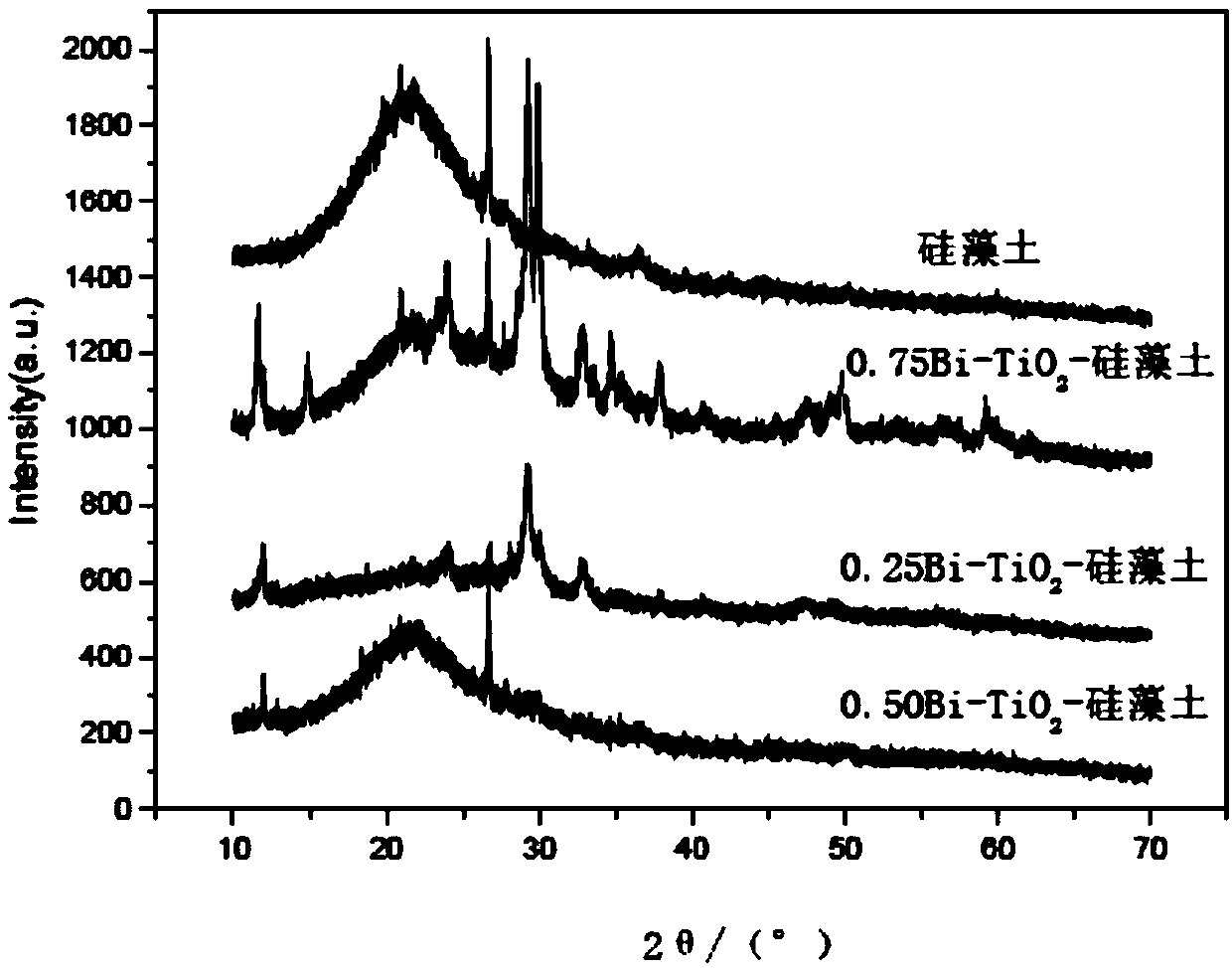

Image

Examples

Embodiment 1

[0040] Purification of diatomaceous earth, the steps are as follows:

[0041] 1), pickling

[0042] Dilute concentrated sulfuric acid with deionized water into a sulfuric acid solution with a volume concentration of 0.6, constant volume with a volumetric flask, weigh 12g of diatomite raw soil with an electronic balance, and mix it with the configured sulfuric acid solution separately. Place on a magnetic stirrer and stir for 12 hours. Suction filter and wash the solution with deionized water, rinse off the acid solution and metal ion salt solution on the surface of diatomaceous earth, and finally put the filtered solid into a drying oven at 80°C for aging and drying for 12 hours.

[0043] 2), Roasting

[0044] Weigh 12 g of dry diatomite with an electronic balance, place it in a muffle furnace and calcinate at a temperature of 550° C., and set the calcining time to 3 hours to obtain purified diatomite.

[0045] Table 1 purification obtains the composition content of diatomi...

Embodiment 2

[0049] Preparation of TiO by Ultrasonic-Assisted Sol-Gel Method 2 / diatomite composite material method, the steps are as follows:

[0050] (1) Preparation of precursor solution: Measure 10 mL of absolute ethanol (CH 3 CH 2 OH) as a dispersant in a beaker with magnetic stirring, then slowly pour 2.5mL butyl titanate (C 16 h 36 o 4 Ti) was used as the titanium source, and finally 1 mL of glacial acetic acid (CH 3 COOH) as an inhibitor, slowly poured into a beaker; Weighed 5g of purified high-grade diatomite with an electronic balance, slowly poured into a beaker, and stirred for 1h;

[0051] (2) Prepare the aqueous solution: use a pipette to measure 0.4mL deionized water into a beaker (dry before use), then pour 5ml of absolute ethanol (CH 3 CH 2 OH), and finally add 1ml of dilute hydrochloric acid to adjust the pH of the solution so that pH=3;

[0052] (3) Add the solution prepared in the second step to the precursor solution dropwise at a rate of 10 drops / min, and keep...

Embodiment 3

[0056] Preparation of Mn-doped TiO by Ultrasonic-Assisted Sol-Gel Method 2 / diatomite composite material method, the steps are as follows:

[0057] (1) Preparation of precursor solution: Measure 10 mL of absolute ethanol (CH 3 CH 2 OH) as a dispersant in a beaker with magnetic stirring, then slowly pour 2.5mL butyl titanate (C 16 h 36 o 4 Ti) was used as the titanium source, and finally 1 mL of glacial acetic acid (CH 3 COOH) as an inhibitor, slowly poured into a beaker; Weighed 5g of purified high-grade diatomite with an electronic balance, slowly poured into a beaker, and stirred for 1h;

[0058] (2) Prepare ionic solution: use a pipette to measure 0.4mL deionized water into a beaker (dried before use), then pour 5mL of absolute ethanol (CH 3 CH 2 OH), and finally add 1mL of dilute hydrochloric acid to adjust the pH of the solution to pH=3; weigh a certain mass of manganese chloride with a balance (control the molar ratio of manganese chloride to titanium dioxide to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com