A kind of light alkane dehydrogenation catalyst and method for preparing light alkene

A dehydrogenation catalyst and a technology for low-carbon alkanes, which are applied in the field of low-carbon alkane dehydrogenation catalysts and the preparation of low-carbon olefins, and can solve the problems of not providing stability data in the carbon burning regeneration process, and decreasing activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

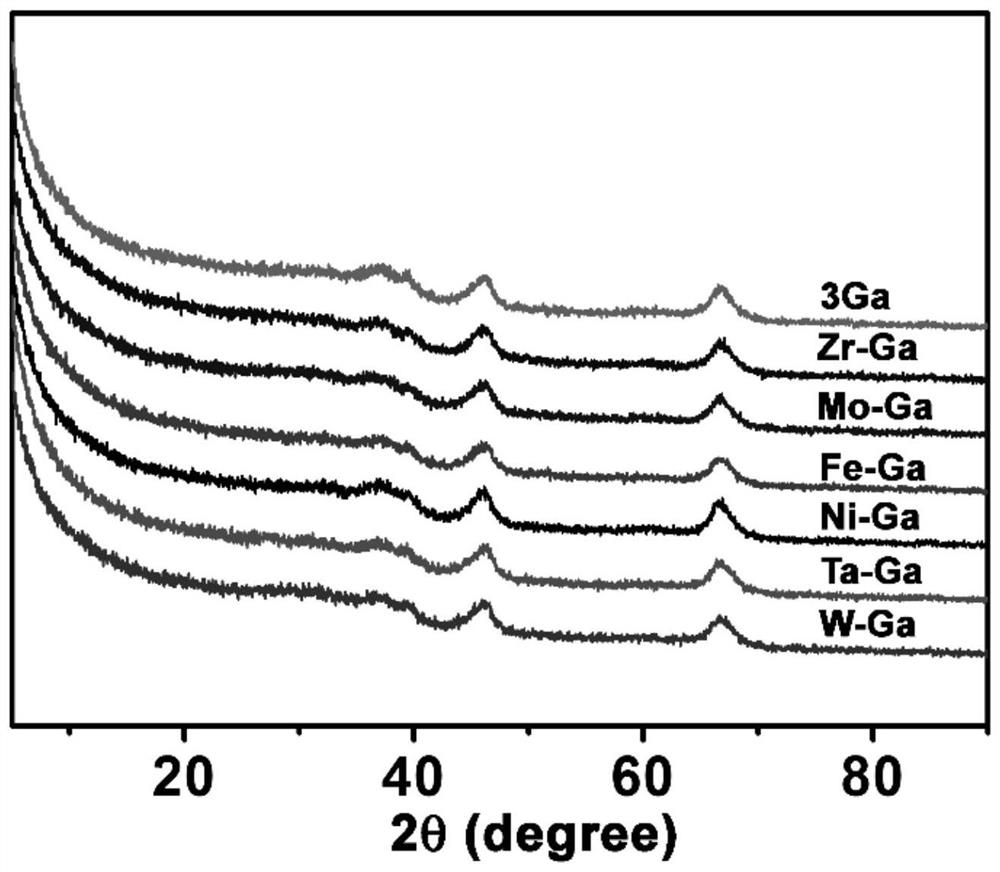

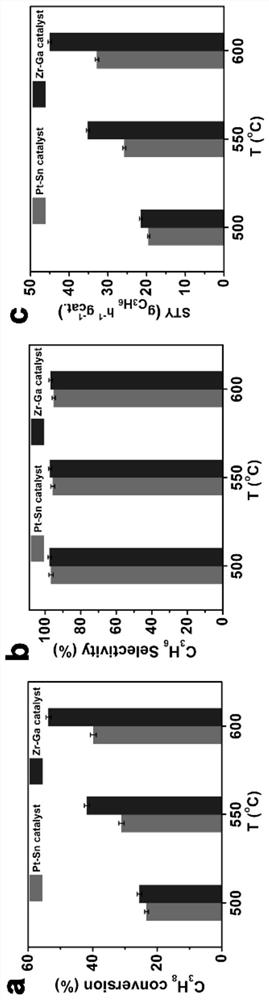

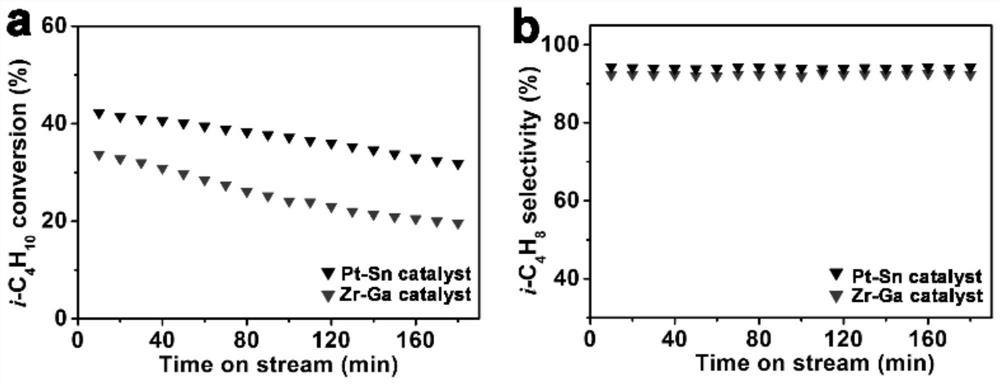

Embodiment 1

[0033] Put the silicon-alumina molecular sieve carrier with a silicon-aluminum mass ratio of 10 into a drying oven at 100° C. to dry overnight, and weigh 96 g of the carrier for use.

[0034] a) Prepare mixed solution: weigh 1g of zirconium nitrate and 3g of gallium nitrate and dissolve in water to prepare mixed solution;

[0035] b) Impregnation: adding the above-mentioned prepared mixed solution dropwise into the reactor equipped with the dried silica-alumina molecular sieve carrier, and keeping gentle stirring;

[0036] c) Stand still: put the above-mentioned impregnated slurry into an oven, and let it stand overnight at 100° C., so that the zirconium-gallium ions can be fully impregnated on the surface and pores of the carrier;

[0037] d) High-temperature calcination: put the crude product after standing still in a muffle furnace for high-temperature calcination at 750° C. for 2 hours, and the calcination atmosphere is air.

[0038] Obtain the catalyst sample of correspo...

Embodiment 2

[0040] Put the silicon-alumina molecular sieve carrier with a silicon-aluminum mass ratio of 10 into a drying oven at 100° C. to dry overnight, and weigh 96 g of the carrier for use.

[0041] a) Prepare mixed solution: take ammonium molybdate and gallium nitrate in proportion and dissolve in water to prepare mixed solution;

[0042] b) Impregnation: adding the above-mentioned prepared mixed solution dropwise into the reactor equipped with the dried silica-alumina molecular sieve carrier, and keeping gentle stirring;

[0043] c) Stand still: put the above-mentioned impregnated slurry into an oven, and let it stand overnight at 100°C, so that the molybdenum-gallium ions can be fully impregnated on the surface of the carrier and in the pores;

[0044] d) High-temperature calcination: put the crude product after standing still in a muffle furnace for high-temperature calcination at 750° C. for 2 hours, and the calcination atmosphere is air.

[0045] Obtain the catalyst of correspon...

Embodiment 3

[0047] Put the silicon-alumina molecular sieve carrier with a silicon-aluminum mass ratio of 10 into a drying oven at 100° C. to dry overnight, and weigh 96 g of the carrier for use.

[0048] a) Prepare mixed solution: take ferric nitrate and gallium nitrate in proportion and dissolve them in water to prepare mixed solution;

[0049] b) Impregnation: adding the above-mentioned prepared mixed solution dropwise into the reactor equipped with the dried silica-alumina molecular sieve carrier, and keeping gentle stirring;

[0050] c) Stand still: put the above-mentioned impregnated slurry into an oven, and let it stand overnight at 100° C., so that the iron gallium ions can be fully impregnated on the surface of the carrier and in the pores;

[0051] d) High-temperature calcination: put the crude product after standing still in a muffle furnace for high-temperature calcination at 750° C. for 4 hours, and the calcination atmosphere is air.

[0052] Obtain the catalyst of correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com