Partially reduced graphene oxide, preparation method and application thereof

A graphene and graphene technology, applied in the field of partially reduced graphene oxide and its preparation, can solve the problems of laborious screening of aggregation crystallization and cross-linking conditions, difficult to become the preferred catalyst for bioprocess engineers, and limited reactor configuration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: the preparation of carrier

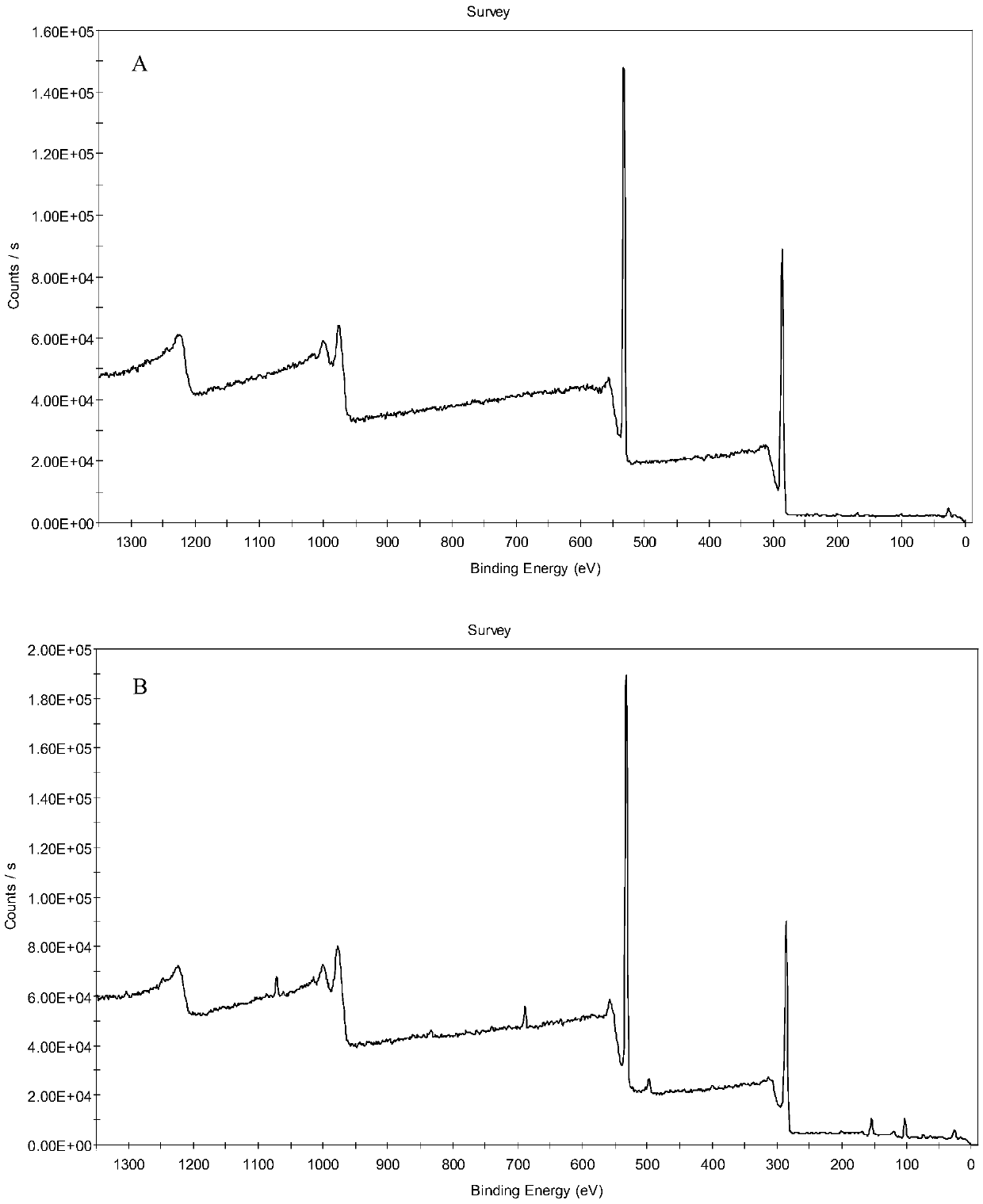

[0044] 20 mg of graphene oxide powder was dissolved in 40 ml of pure water, and it was sufficiently dispersed by ultrasound to prepare a 0.5 g / L graphene oxide dispersion. Take the graphene oxide dispersion (0.5g / L), add 20mg of disodium guanylate, fully dissolve, and react in a magnetically stirred water bath at 25°C for 6h, and finally centrifuge, wash, and freeze-dry to obtain the desired carrier GMPNa 2 -GO. The graphene oxide dispersion was taken for centrifugation and freeze-drying. Take equal amounts of graphene oxide and GMPNa 2 -GO solid, ground into powder, and carried out XPS analysis, confirmed that GO was modified, such as figure 1 .

Embodiment 2

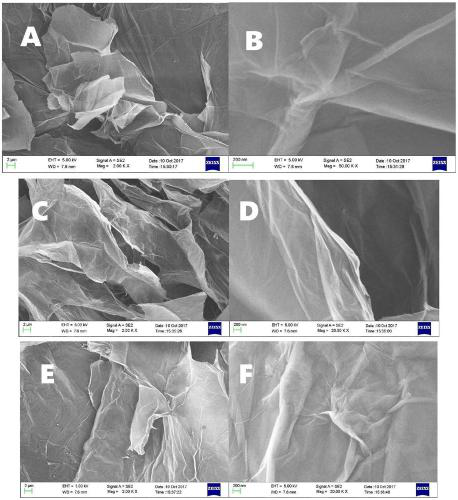

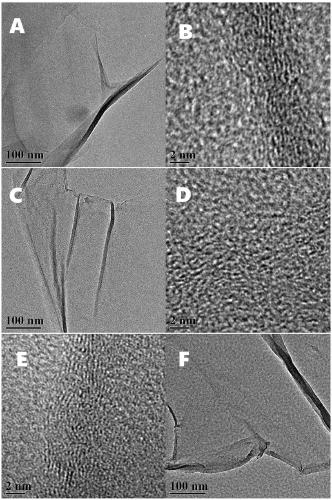

[0045] Embodiment 2: the influence of reducing agent dosage on GO

[0046] 20 mg of graphene oxide powder was dissolved in 40 ml of pure water, and it was sufficiently dispersed by ultrasound to prepare a 0.5 g / L graphene oxide dispersion. Take the graphene oxide dispersion (0.5g / L), add 20mg and 80mg disodium guanylate respectively, fully dissolve, and react in a magnetically stirred water bath at 25°C for 6h, and finally centrifuge, wash, and freeze-dry to obtain Required carrier GMPNa 2 -GO. The graphene oxide dispersion was reacted in a magnetically stirred water bath at 25°C for 6 hours, and finally centrifuged and freeze-dried. Take equal amounts of graphene oxide and GMPNa 2 -GO solid, ground into powder, and carried out SEM, TEM analysis, confirmed that GO was modified, such as figure 2 , image 3 .

Embodiment 3

[0047] Example 3: The effect of the reduction degree of the carrier on the activity of the immobilized enzyme.

[0048] 20 mg of graphene oxide powder was dissolved in 40 ml of pure water, and it was sufficiently dispersed by ultrasound to prepare a 0.5 g / L graphene oxide dispersion. Take the graphene oxide dispersion (0.5g / L), add 20mg, 40mg, and 80mg of disodium guanylate respectively, fully dissolve, and react in a magnetically stirred water bath at 25°C for 6h, and finally perform centrifugation, washing, and freeze-drying , to obtain carriers with different degrees of reduction (GMPNa 2 -0.5g / L-GO, GMPNa 2 -1g / L-GO, GMPNa 2 -2g / L-GO). The graphene oxide dispersion was taken for centrifugation and freeze-drying. Take the same amount of graphene oxide and different reduction degrees of GMPNa 2 -GO solid, ground into powder, and carried out XPS analysis, confirmed that GO was modified, such as Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com