Method for preparing benzonitrile from waste polyphthalate plastic

A technology of polyterephthalate and phthalate, which is applied in the field of organic matter preparation, can solve problems such as unseen benzonitrile, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

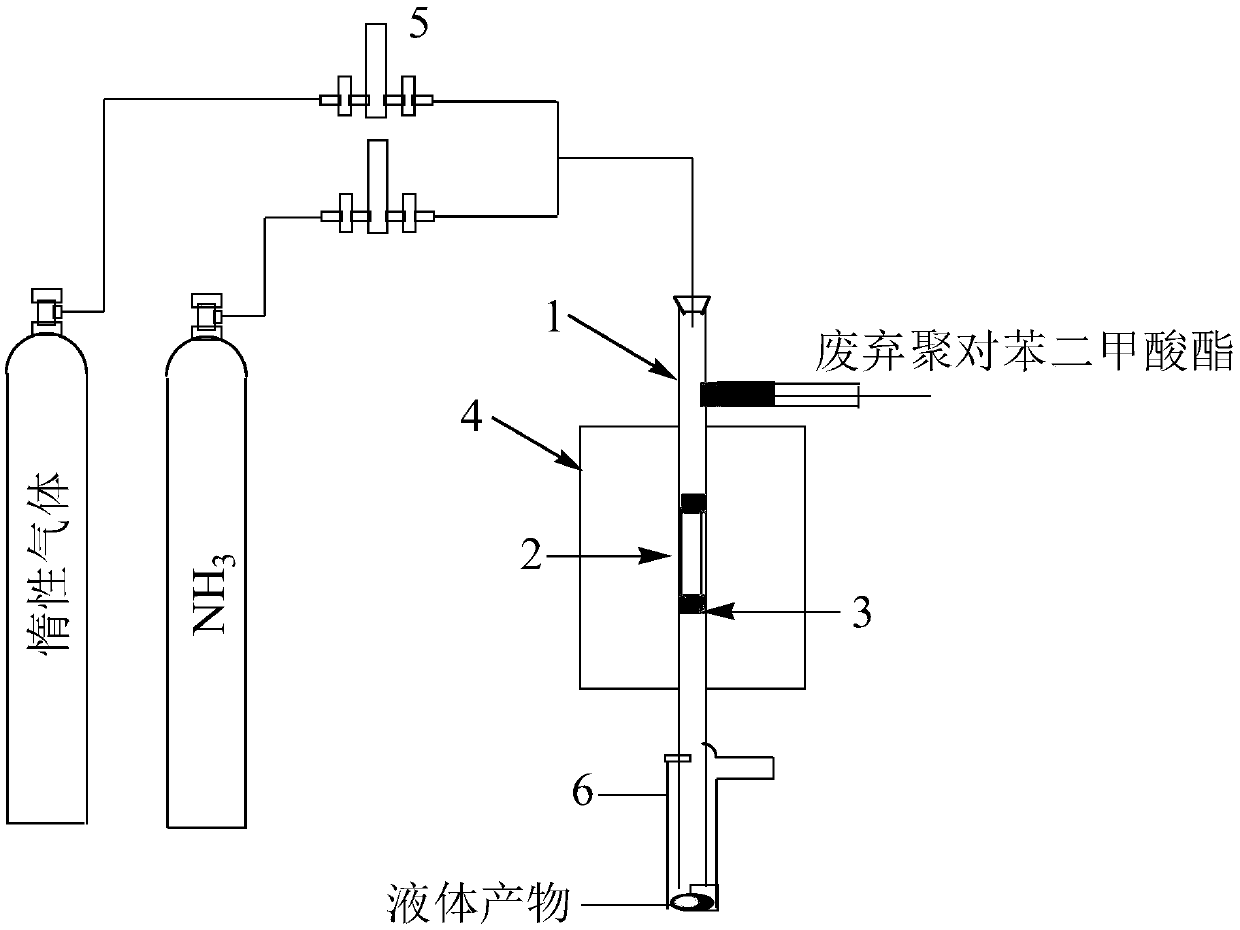

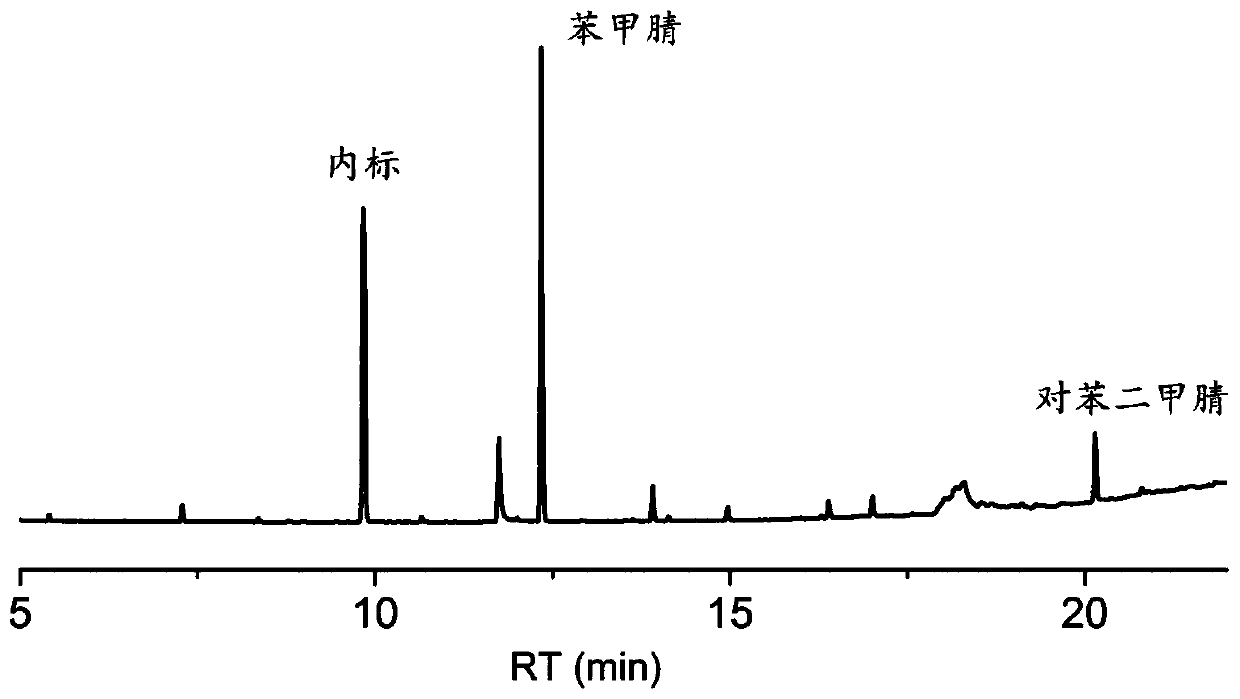

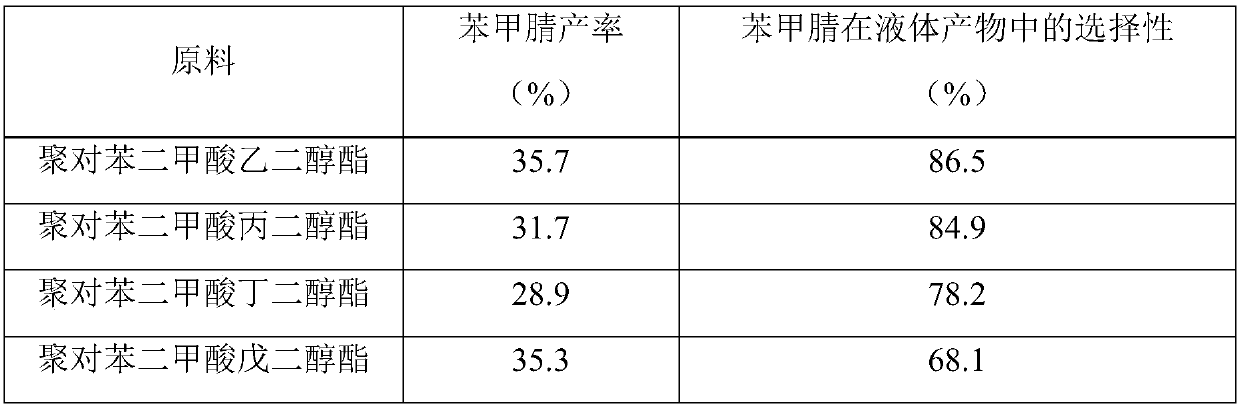

[0028] like figure 1 , in quartz tubular reactor 1 (diameter 10mm, length 250mm), packing catalyst 5%-CaO / Al 2 o 3 , the catalyst is supported by quartz wool 3 to form a catalyst bed 2; the quartz reactor is installed in a temperature-controlled furnace 4, and the temperature of the reactor is monitored by a thermocouple inserted into the surface of the temperature-controlled furnace packed bed. Using NH 3 / N 2 Mixed gas is used as carrier gas, and the ammonia flow rate=80mL / min is controlled by gas flow meter 5, N 2 = 80 mL / min. The raw material of polyethylene terephthalate powder (100 mesh) flows from the opening of the quartz tube reactor to the pyrolysis interface together with the carrier gas flow, and the mass space velocity WHSV of polyethylene terephthalate is 10h -1 , the reaction temperature is controlled at 600°C, the reaction is carried out under the catalysis of the catalyst, the liquid product flows from the reactor to the condenser 6, and the gas product i...

Embodiment 2

[0034] Using polyethylene terephthalate (100 mesh particle size) as raw material, NH 3 As carrier gas (ammonia flow = 160mL / min), 5%-CaO / Al 2 o 3 For catalyst, WHSV 10h -1 ; To test the influence of different reaction temperatures on the yield and selectivity of benzonitrile.

[0035] The impact of table 2 different temperatures on benzonitrile

[0036]

Embodiment 3

[0038] Using polyethylene terephthalate (100 mesh particle size) as raw material, reaction conditions: reaction temperature is 650°C; ammonia gas flow rate = 60mL / min; WHSV 10h -1 . The effect of different catalysts on the yield and selectivity of benzonitrile was tested.

[0039] The influence of table 3 different catalysts on benzonitrile

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com