Denitrification-function filler and preparation and application thereof

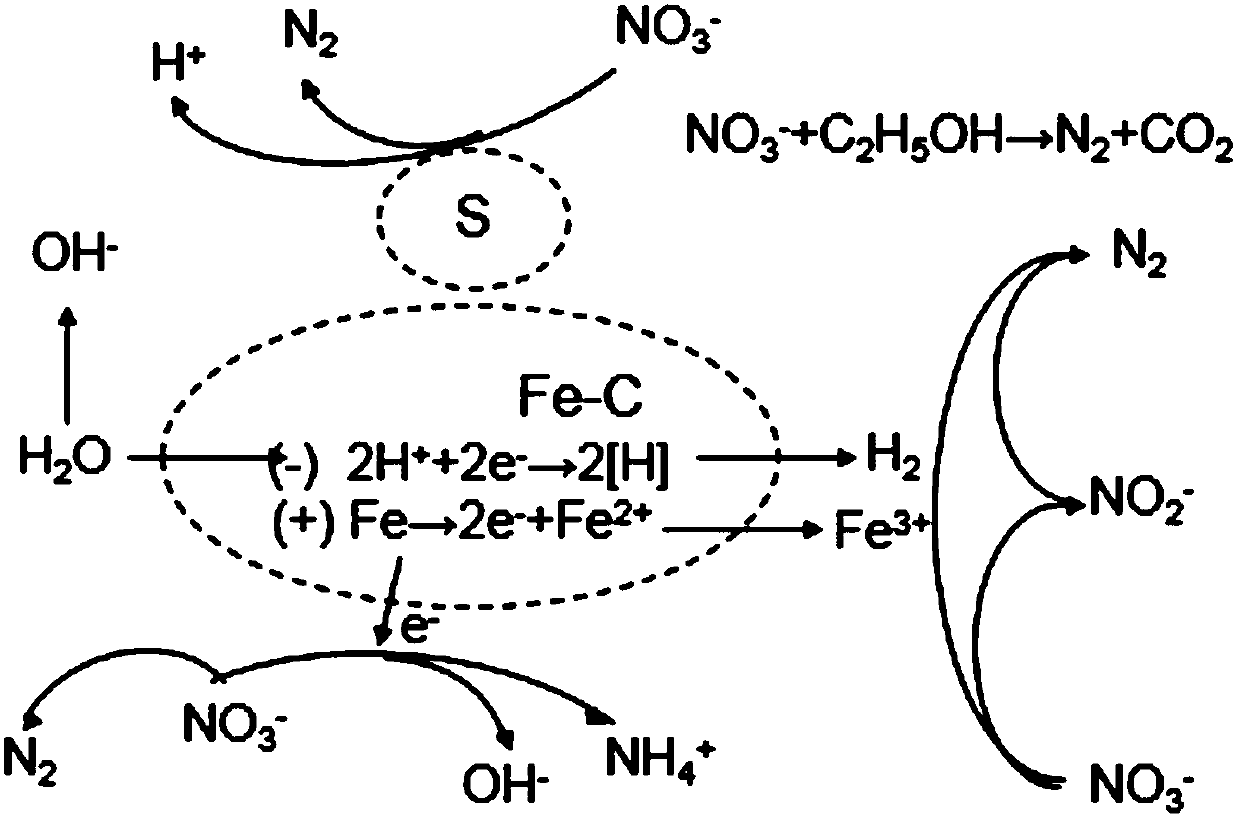

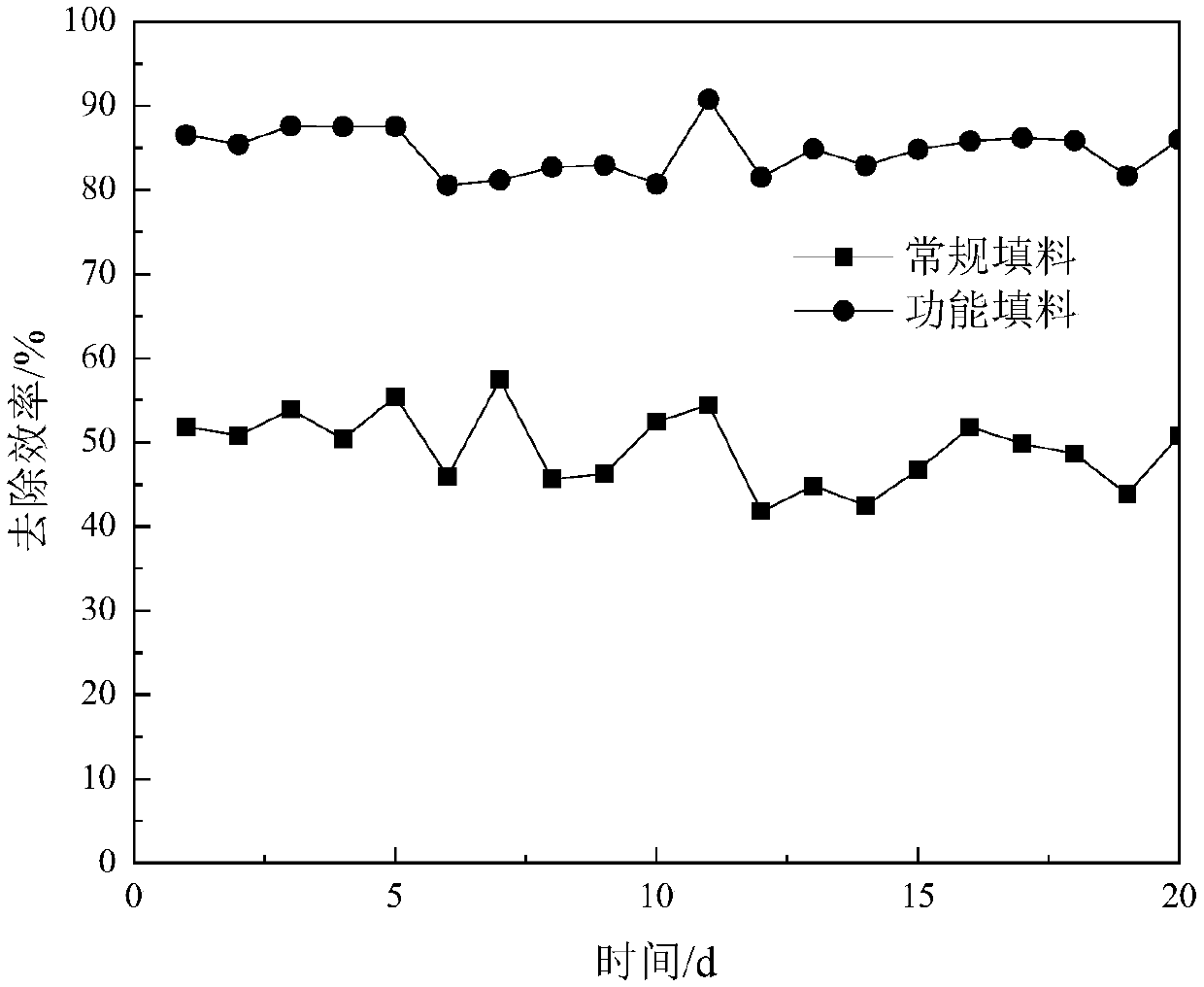

A functional filler and denitrification technology, applied in chemical instruments and methods, granular microbial carrier treatment, sustainable biological treatment, etc., can solve the problems of hindering the growth of microorganisms in micro-electrolysis reactions, unsuitable for microbial growth, and unsuitable for microorganisms. Achieve the effects of avoiding sludge bulking, reducing dosing, and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this example, the denitrification functional filler used in low C / N wastewater biological denitrification technology with reduced carbon source dosage, the preparation steps are as follows:

[0045] 1) Raw material selection: the selected reduced iron powder is 200 mesh; the activated carbon is 200 mesh; the particle size of sulfur particles is 0.5-1mm; the copper powder is 200 mesh;

[0046] 2) Preparation of nitrogen-removing functional filler: Blend and mix each component according to a certain mass ratio, including 30% reduced iron powder, 10% activated carbon, 5% copper powder, 30% sulfur, 15% calcium sulfate, and 5% ammonium bicarbonate , NaOH 5%. Slowly add 15% water of the mass sum of each component to form a viscous mixed material, fill the mixed material into a spherical mold with a particle size of 9mm, and dry the material in a vacuum oven at 60°C for 8 hours. Then take it out from the mold, and dry it in a vacuum drying oven at 100°C to make holes, and ...

Embodiment 2

[0050] In this example, the denitrification functional filler used in low C / N wastewater biological denitrification technology with reduced carbon source dosage, the preparation steps are as follows:

[0051] 1) Raw material selection: the selected reduced iron powder is 200 mesh; the activated carbon is 200 mesh; the sulfur particle size is 0.5-1mm; the copper powder is 200 mesh; the magnesium powder is 200 mesh;

[0052] 2) Preparation of nitrogen-removing functional filler: Blend and mix each component according to a certain mass ratio, including 30% reduced iron powder, 10% activated carbon, 3% copper powder, 2% magnesium powder, 30% sulfur, and 15% sodium alginate , Ammonium Bicarbonate 5%, Sodium Dihydrogen Phosphate 5%. Slowly add 15% water of the mass sum of each component to form a viscous shape, fill the mixed material into a spherical mold with a particle size of 9mm, dry the material in a vacuum oven at 60°C for 8 hours, and then remove it from the mold Take it ou...

Embodiment 3

[0056] In this example, the denitrification functional filler used in low C / N wastewater biological denitrification technology with reduced carbon source dosage, the preparation steps are as follows:

[0057] 1) Selection of raw materials: the selected reduced iron powder is 200 mesh; the activated carbon is 200 mesh; the particle size of sulfur particles is 0.5-1mm; the manganese powder is 200 mesh; the tin powder is 200 mesh;

[0058] 2) Preparation of nitrogen-removing functional filler: mix and mix the components according to a certain mass ratio, including 25% reduced iron powder, 8% activated carbon, 3% manganese powder, 2% tin powder, 38% sulfur, 18% gum arabic, Ammonium oxalate 3%, calcium carbonate 3%. Slowly add 15% water of the mass sum of each component to form a viscous shape, fill the mixed material into a spherical mold with a particle size of 9mm, dry the material in a vacuum oven at 60°C for 8 hours, and then remove it from the mold Take it out and dry it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com