Reactive distillation method for preparing cyclohexanol through hydration of cyclohexene and device of method

A cyclohexene hydration and reactive distillation technology, which is applied in the field of cyclohexene hydration to prepare cyclohexanol reactive distillation and its device, can solve the problems of resin catalyst strength pulverization, insufficient reaction speed, adhesion, etc. Achieve the effects of reducing steam flow velocity, increasing single-pass conversion rate, and reducing reaction energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

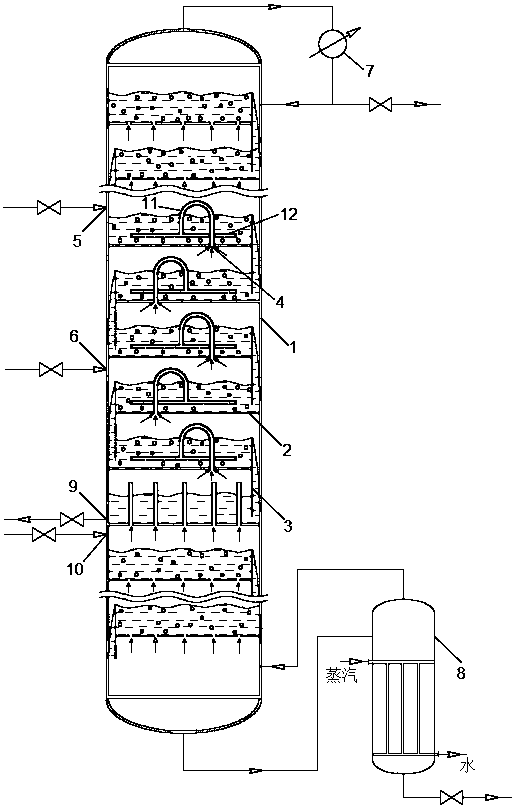

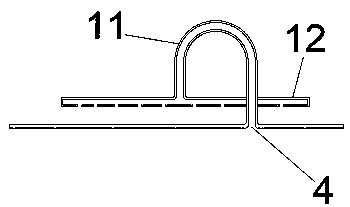

[0058] The diameter of the reactive distillation column is 450mm, the column height is 14500mm, and the total number of trays is 29. Process conditions in the reactive distillation tower: cyclohexene flow rate is 80kmol / h, 18-crown-6 flow rate is 80kmol / h, water flow rate is 320kmol / h, ZSM-5 molecular sieve catalyst mass concentration is 35%, reaction temperature The temperature is 130°C, and the reaction pressure is 0.55MPa. The particle size of the ZSM-5 molecular sieve catalyst is 2.5 μm, and the acidity of the filtrate is 0.22 mmol / g. The air inlet on the non-porous tray assembly is 14mm; the diameter of the U-shaped vapor rising pipe in the non-porous tray assembly is 24mm, and the height is 320mm; the annular gas distribution in the non-porous tray assembly is The diameter of the device is 100 mm, and the opening rate is 15%.

[0059] Water, ZSM-5 molecular sieve catalyst and 18-crown ether-6 are fed into the reactive distillation column from the feed port (a) at the s...

Embodiment 2

[0062] The diameter of the reactive distillation column is 450mm, the column height is 14500mm, and the total number of trays is 29. Process conditions in the reactive distillation tower: cyclohexene flow rate is 70kmol / h, 15-crown-5 flow rate is 49kmol / h, water flow rate is 140kmol / h, ZSM-5 molecular sieve catalyst mass concentration is 15%, reaction temperature is 120°C, and the reaction pressure is 0.35MPa. The particle size of the ZSM-5 molecular sieve catalyst is 1 μm, and the acidity of the filtrate is 0.25 mmol / g. The size of the air inlet on the non-porous tray assembly in the non-porous tray assembly is 10mm; the diameter of the U-shaped vapor rising pipe in the non-porous tray assembly is 15mm, and the height is 200mm; the annular gas distribution in the non-porous tray assembly The diameter of the device is 80mm, and the opening rate is 8%.

[0063] Water, ZSM-5 molecular sieve catalyst and 15-crown ether-5 are fed into the reactive distillation column from the fe...

Embodiment 3

[0066] The diameter of the reactive distillation column is 450mm, the column height is 14500mm, and the total number of trays is 29. The process conditions in the reactive distillation tower: the flow rate of cyclohexene is 60kmol / h, the flow rate of pyridine is 102kmol / h, the flow rate of water is 180kmol / h, the mass concentration of ZSM-5 molecular sieve catalyst is 20%, the reaction temperature is 140°C, the reaction The pressure is 0.45MPa. The particle size of the ZSM-5 molecular sieve catalyst is 1.4 μm, and the acidity of the filtrate is 0.18 mmol / g. The air inlet on the non-porous tray assembly is 12mm; the diameter of the U-shaped vapor rising pipe in the non-porous tray assembly is 19mm, and the height is 240mm; the annular gas distribution in the non-porous tray assembly is The diameter of the device is 85mm, and the opening rate is 10%.

[0067] Water, ZSM-5 molecular sieve catalyst and pyridine are fed into the reactive distillation column from the feed port (a)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com