Preparation method and application of self-floating high-efficiency photothermal conversion seawater desalination material

A light-to-heat conversion, self-floating technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, seawater treatment, etc., to prevent large losses of thermal energy, enhance absorption, and generate high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

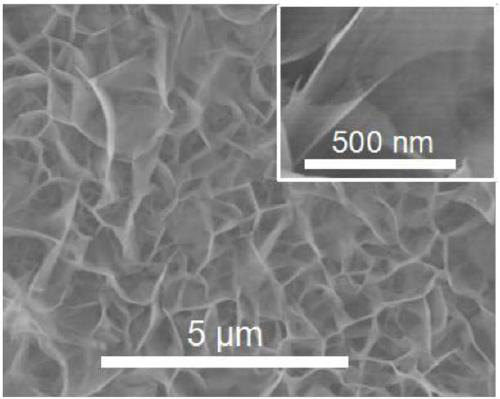

[0034] Example 1: Using a hydrothermal synthesis method, nickel black, a self-floating high-efficiency light-to-heat conversion seawater desalination material, is grown on a clean nickel foam base material.

[0035] 1) Ultrasonic clean the purchased nickel foam with 3M dilute hydrochloric acid, ethanol, and deionized water for 30 minutes, 15 minutes, and 15 minutes respectively, and then place it in a constant temperature drying oven at 60°C for 12 hours.

[0036] 2) Add nickel nitrate hexahydrate and hexamethylenetetramine into a beaker with 40ml of deionized water, the ratio is 1:2, place on a stirring table and stir evenly to form a uniform and transparent solution, transfer the solution to a 100ml In the reactor, cut the nickel foam obtained in step 1) into 2*2cm 2 The size, together into the reactor, hydrothermal synthesis 100 ℃, 10h.

[0037] 3) The material obtained in (2) was repeatedly washed with deionized water, and dried at 60° C. to obtain an intermediate product...

Embodiment 2

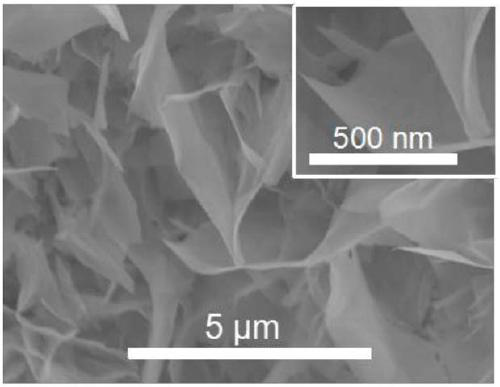

[0044] Example 2: Using a hydrothermal synthesis method, an iron / defect-rich iron oxide composite is grown on a clean nickel foam base material.

[0045] 1) Ultrasonic clean the purchased nickel foam with 3M dilute hydrochloric acid, ethanol, and deionized water for 30 minutes, 15 minutes, and 15 minutes respectively, and then place it in a constant temperature drying oven at 60°C for 12 hours.

[0046] 2) Add ferric chloride hexahydrate and hexamethylenetetramine into a beaker with 40ml of deionized water, the ratio is 1:2, place on a stirring table and stir evenly to form a uniform and transparent solution, transfer the solution to 100ml In the reaction kettle, cut the nickel foam obtained in step 1) into 2*2cm 2 The size, together into the reactor, hydrothermal synthesis 100 ℃, 10h.

[0047] 3) The material obtained in (2) was repeatedly washed with deionized water, and dried at 60° C. to obtain an intermediate product—a foamed nickel-based material with ferric hydroxide. ...

Embodiment 3

[0052] Example 3: Using the method of hydrothermal synthesis, a self-floating high-efficiency photothermal conversion seawater desalination material copper / defective copper oxide composite is grown on a clean nickel foam base material.

[0053] 1) Ultrasonic clean the purchased nickel foam with 3M dilute hydrochloric acid, ethanol, and deionized water for 30 minutes, 15 minutes, and 15 minutes respectively, and then place it in a constant temperature drying oven at 60°C for 12 hours.

[0054] 2) Add copper chloride dihydrate and hexamethylenetetramine into a beaker with 40ml of deionized water, the ratio is 1:2, place on a stirring table and stir evenly to form a uniform and transparent solution, transfer the solution to 100ml In the reaction kettle, cut the nickel foam obtained in step 1) into 2*2cm 2 The size, together into the reactor, hydrothermal synthesis 100 ℃, 10h.

[0055] 3) The material obtained in (2) was repeatedly washed with deionized water, and dried at 60° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com