A natural corn cotton cup

A technology of corn and cotton cups, which is applied in the field of bras and underwear, can solve the problems of easily induced mastitis, unfavorable human health, greenhouse gas emission, etc., and achieve the effect of achieving reproducibility, not easy to breed bacteria and viruses, and good support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

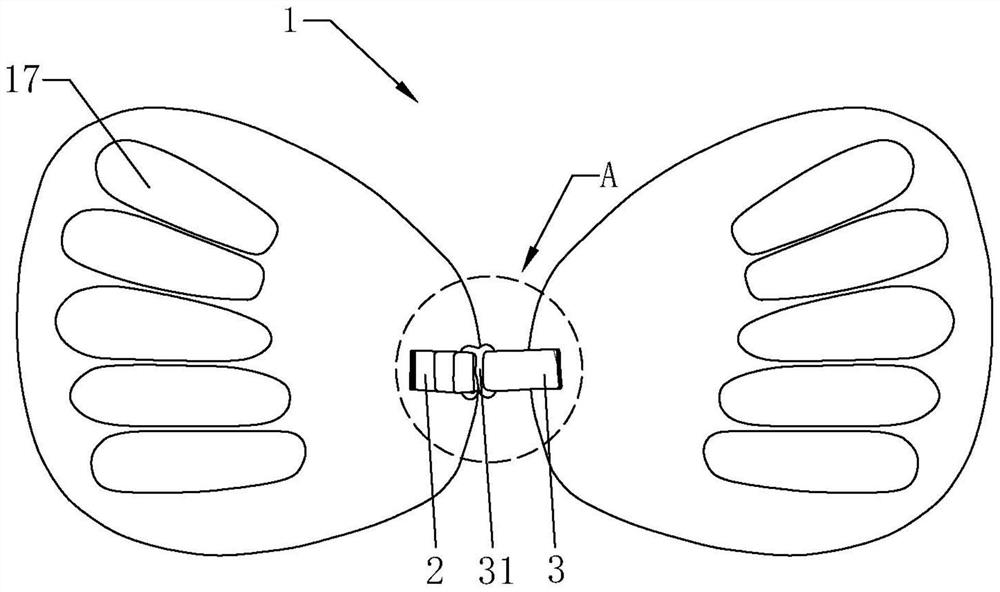

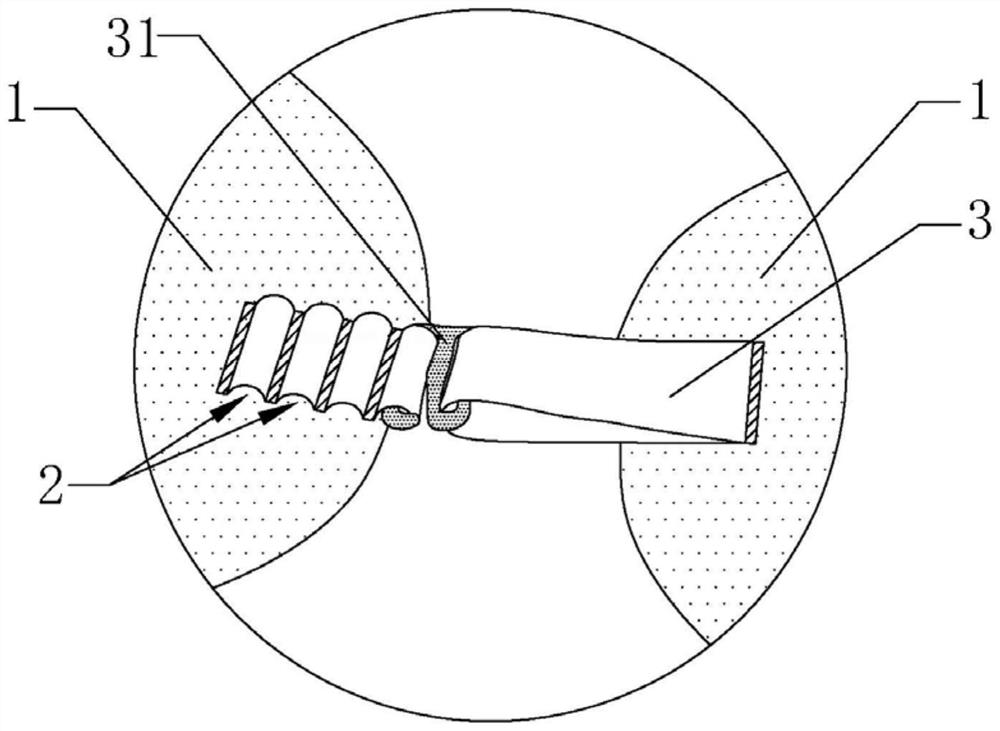

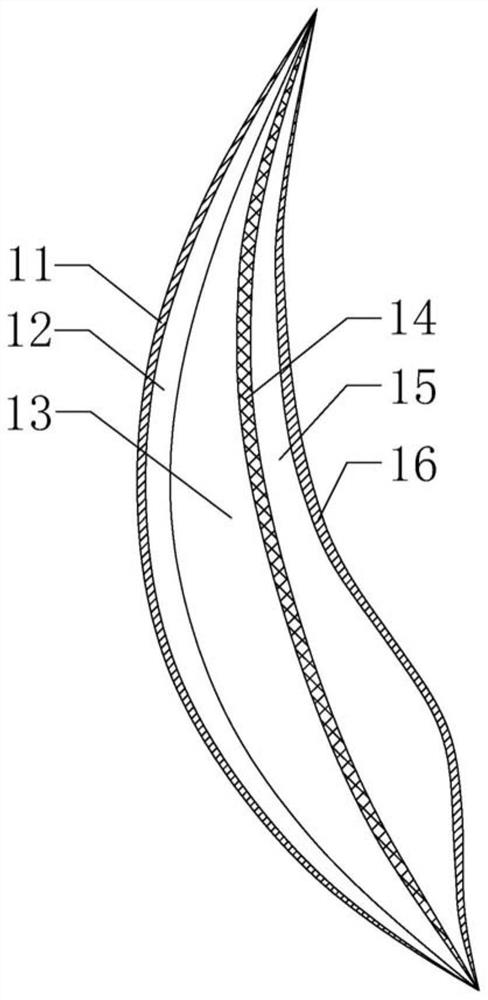

[0052] See Figure 1-3 , a natural corn cotton cup, comprising two symmetrically arranged cups 1, said cup 1 comprising a first cotton cloth layer 11, a first corn cotton layer 12, a second corn cotton layer 13, glue Mesh layer 14, the third corn cotton layer 15 and the second cotton cloth layer 16; The first corn cotton layer 12, the second corn cotton layer 13 and the third corn cotton layer 15 are all made of corn fiber weaving; the cup 1. A hand-push part 17 is provided on the side away from the chicken heart, and the hand-push part 17 is molded by the third corn cotton layer 15.

[0053] The thickness of the first corn cotton layer 12 is 3.5-4.5mm, the thickness of the second corn cotton layer 13 is 17-19mm, and the thickness of the third corn cotton layer 15 is 7.5-8.5mm. The thickness of the first cotton layer 11 and the second cotton layer 16 is 0.8-1.2mm, the thickness of the glue mesh layer 14 is 1-2mm, and the mesh density of the glue mesh layer 14 is 28-32 pieces / ...

Embodiment 2

[0056] The difference between this embodiment and above-mentioned embodiment 1 is:

[0057] The corn fiber is made from polylactic acid masterbatch, and the polylactic acid masterbatch includes the following raw materials in parts by weight:

[0058]

[0059] The inorganic filler includes 5 parts of mica powder, 1 part of aluminum oxide, 1 part of calcium carbonate and 2 parts of cordierite powder; A mixture of lactone and alkylbis(α-hydroxyethylamine phosphate) in a weight ratio of 2:1:1.8.

[0060] The antioxidant is composed of β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate and tris(nonylphenyl)phosphite in a weight ratio of 2:1. Mixture; the surfactant is a mixture of fatty acid polyoxyethylene ester and alkylphenol polyoxyethylene ether in a weight ratio of 3:1.

[0061] The coupling agent is vinyltriethoxysilane; the dispersion stabilizer is p-hydroxyanisole; the solvent is a mixture of ethyl acetate, ethanol and water in a weight ratio of 1.5:2:1 .

...

Embodiment 3

[0076] The difference between this embodiment and above-mentioned embodiment 1 is:

[0077] The corn fiber is made from polylactic acid masterbatch, and the polylactic acid masterbatch includes the following raw materials in parts by weight:

[0078]

[0079] The inorganic filler includes 5.2 parts of mica powder, 1.5 parts of aluminum oxide, 1.2 parts of calcium carbonate and 2.2 parts of cordierite powder; A mixture of lactone and alkylbis(α-hydroxyethylamine phosphate) in a weight ratio of 2.2:1:2.0.

[0080] The antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) stearyl propionate and three (nonyl phenyl) phosphite with a weight ratio of 2.2:1. Mixture; the surfactant is a mixture of fatty acid polyoxyethylene ester and alkylphenol polyoxyethylene ether in a weight ratio of 3.2:1.

[0081] Described coupling agent is pyrophosphate ester titanate; Described dispersion stabilizer is 2,5-di-tert-butyl hydroquinone; Described solvent is to be 1.5 by weight ratio with et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com