A kind of macroporous kaolinite and its preparation and application

A technology for kaolinite and kaolinite, applied in the field of kaolinite and its preparation, can solve the problems of difficult filtration, small particle size of kaolinite, and high industrial production cost, and achieves low dry gas selectivity, high and medium pore content, and high total pore size. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

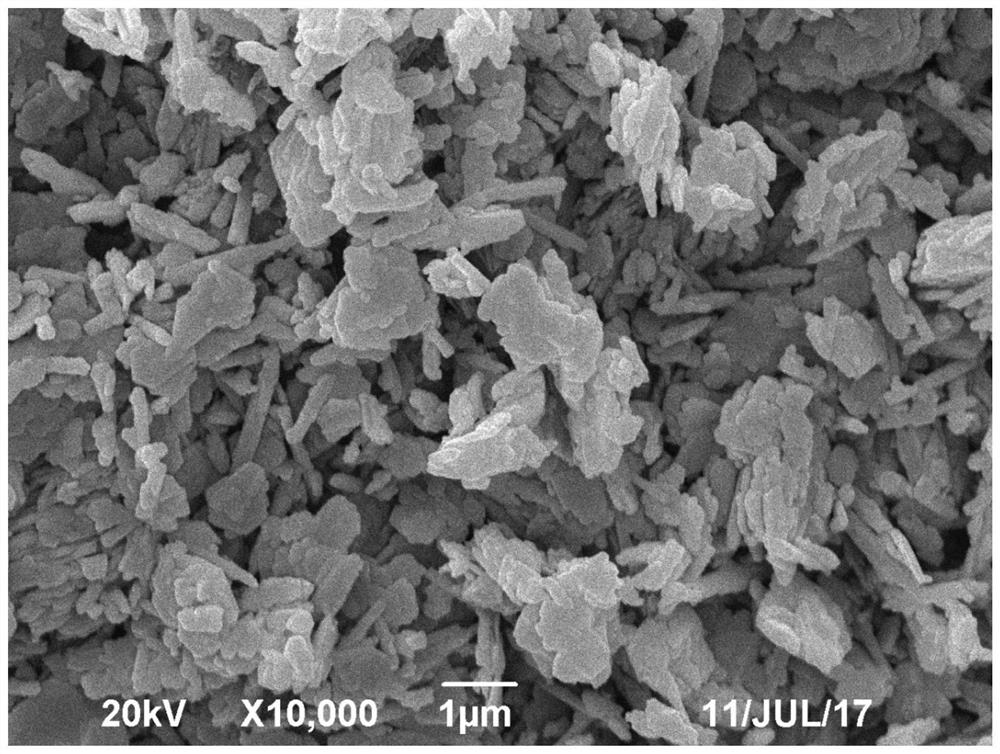

Image

Examples

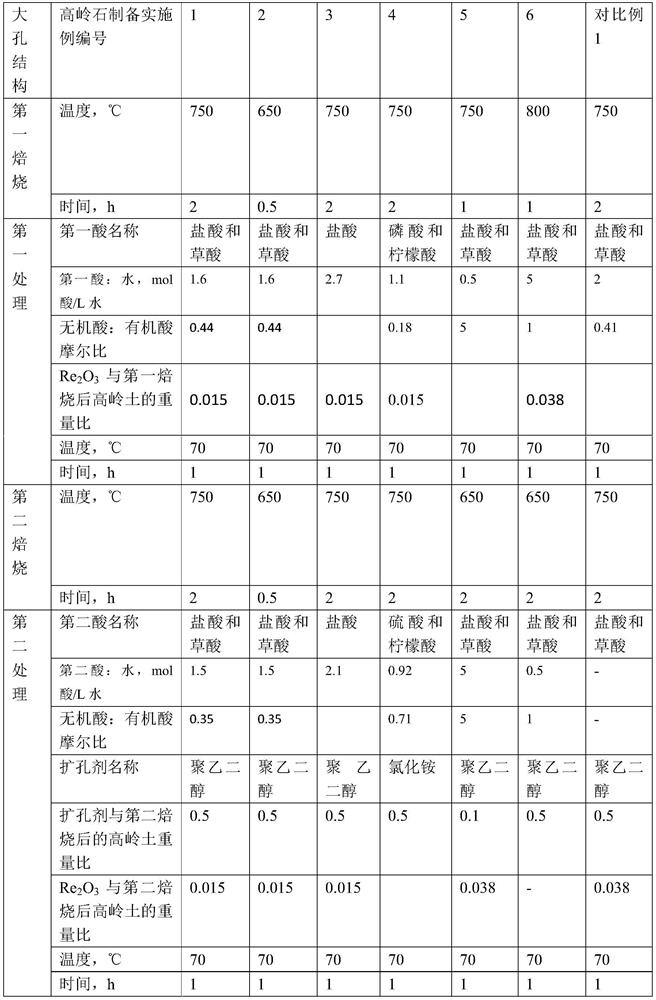

preparation Embodiment 1

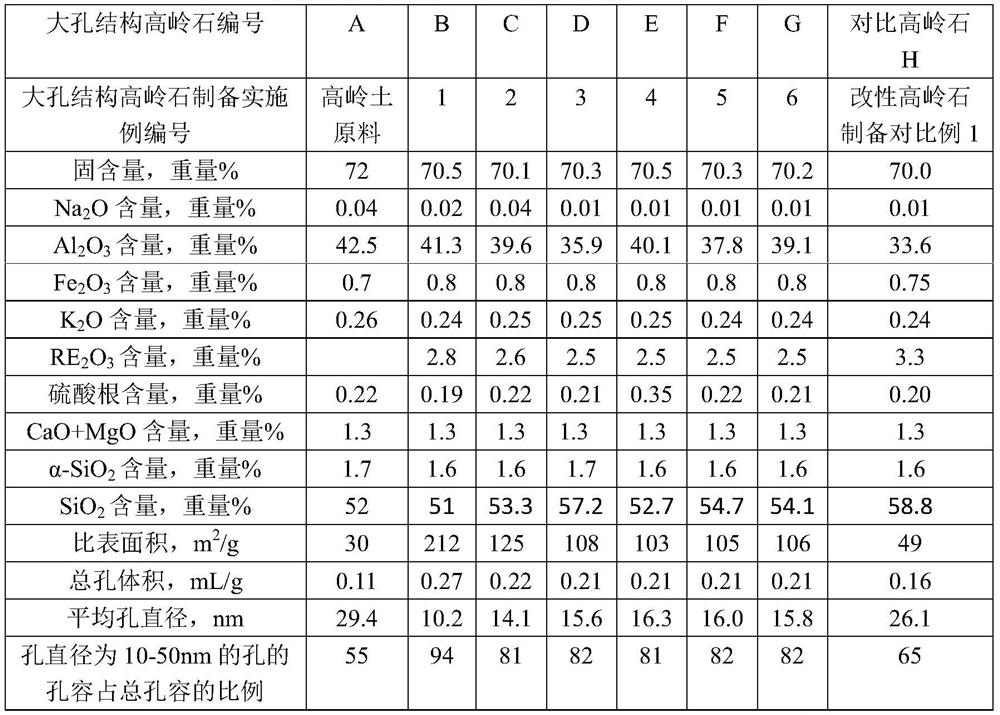

[0075] Kaolin A was roasted at 750° C. for 2 hours to obtain a roasted material (called the first roasted material), and 168 g (dry basis, the same below) of the roasted material was added to decationized water (pH=3.1, the same below) and stirred to prepare To form a slurry with a solid content of 25% by weight, add 500 g of hydrochloric acid and 100 g of oxalic acid with a concentration of 1 mol / L, stir for 10 minutes, then add 7.6 mL of rare earth solution under stirring, heat up to 70 ° C, stir for 1 hour, then filter to remove the mother liquor, filter The cake is dried to obtain the first step product; 120g of the first step product is roasted at 750°C for 2 hours to obtain a roasted material (called the second roasted material), and 100g (dry basis, the same below) is added to the second roasted material for decationization Stir with water to obtain a slurry with a solid content of 25% by weight, add 200 g of hydrochloric acid, 50 g of oxalic acid, and 50 g of polyethyle...

preparation Embodiment 2

[0077] Kaolin A was roasted at 650° C. for 0.5 hour to obtain a roasted material (referred to as the first roasted material). 168 g of the first roasted material was added to decationized water and stirred to obtain a slurry with a solid content of 25% by weight. 500g of hydrochloric acid and 100g of oxalic acid, stirred for 10 minutes, then added 7.6mL of rare earth solution while stirring, raised the temperature to 70°C, stirred for 1 hour, then filtered to remove the mother liquor, and dried the filter cake to obtain the first step product; 120g of the first step product Roast at 650° C. for 0.5 hour to obtain a roasted material (called the second roasted material), add acidic water (decationized water) to 100 g of the second roasted material and stir to obtain a slurry with a solid content of 25% by weight, and add a concentration of 1mol / L 200g of hydrochloric acid, 50g of oxalic acid, and 50g of polyethylene glycol were stirred for 7 minutes, then 4.5mL of rare earth solu...

preparation Embodiment 3

[0079] Roasting clay A at 750° C. for 2 hours to obtain a roasted material (called the first roasted material), 168 g of the first roasted material was added with deionized water and stirred to obtain a slurry with a solid content of 25% by weight. 500g of hydrochloric acid, stirred for 10 minutes, then added 7.6mL of rare earth solution under stirring, raised the temperature to 70°C, stirred for 1 hour, then filtered to remove the mother liquor, and dried the filter cake to obtain the first step product; 120g of the first step product was heated at 750°C Lower roasting 2 hours obtains roasted material (called the second roasted material), 100g of the second roasted material is added deionized water and stirred, obtains the slurry that solid content is 25% by weight, adds the hydrochloric acid 200g of concentration 5mol / L, polyethylene glycol 50g, stirred for 7 minutes, then added 4.5mL of rare earth solution under stirring, raised the temperature to 70°C, stirred for 1 hour, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com