High-heat-resistant amorphous polyester preparation method

An amorphous polyester, high heat resistance technology, applied in the field of polyester modification, can solve the problems of difficult production, low reactivity, difficult polymerization process, etc., to avoid yellowish hue, high intrinsic viscosity, and esterification effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

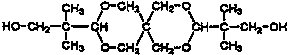

Image

Examples

Embodiment 1

[0025] Add 350 grams of terephthalic acid, 65 grams of spiroglycol, 45 grams of 1,4 cyclohexanedimethanol, 163 grams of ethylene glycol, and 0.0175 monobutyltin oxide into a 2L reaction kettle. Esterification under the conditions of ~260°C and esterification pressure (gauge pressure) 2.5MPa. When the water output reaches the theoretical value, the esterification is terminated and released to normal pressure. Add 0.0261 g of phosphoric acid, continue stirring for 10 minutes, and add ethylene glycol After 0.13 grams of antimony, gradually increase the temperature and enter the low vacuum stage. After the low vacuum time is about 45 minutes, enter the high vacuum polycondensation stage (vacuum <100Pa), the polycondensation temperature is 270 ° C ~ 290 ° C, and the material is discharged when the stirring power reaches the rated value. Synthetic The modified polyester has a glass transition temperature of 107°C, an intrinsic viscosity of 0.862dL / g, a terminal carboxyl group of 28mo...

Embodiment 2

[0027] Add 350 grams of terephthalic acid, 90 grams of spirodiol, 48.5 grams of 1,4-cyclohexanedimethanol, 208 grams of ethylene glycol, and 0.070 monobutyltin oxide into a 2L reaction kettle. Esterification under the conditions of ~260°C and esterification pressure (gauge pressure) 2.5MPa. When the water output reaches the theoretical value, the esterification is terminated and released to normal pressure. Add 0.0175 grams of phosphoric acid, continue to stir for 10 minutes, and then add ethylene glycol After 0.13 grams of antimony, gradually increase the temperature and enter the low vacuum stage. After the low vacuum time is about 45 minutes, enter the high vacuum polycondensation stage (vacuum <100Pa), the polycondensation temperature is 270 ° C ~ 290 ° C, and the material is discharged when the stirring power reaches the rated value. Synthetic The modified polyester has a glass transition temperature of 117°C, an intrinsic viscosity of 0.810dL / g, a terminal carboxyl group ...

Embodiment 3

[0029] Add 350 grams of terephthalic acid, 65 grams of spirodiol, 30.5 grams of 1,4-cyclohexanedimethanol, 196 grams of ethylene glycol, and 0.044 monobutyltin oxide into a 2L reaction kettle. Esterification under the conditions of ~260℃ and esterification pressure (gauge pressure) 2.5MPa. When the water output reaches the theoretical value, the esterification is terminated and released to normal pressure. Add 0.035 g of phosphoric acid, continue stirring for 10 minutes, and add ethylene glycol After 0.13 grams of antimony, gradually increase the temperature and enter the low vacuum stage. After the low vacuum time is about 45 minutes, enter the high vacuum polycondensation stage (vacuum <100Pa), the polycondensation temperature is 270 ° C ~ 290 ° C, and the material is discharged when the stirring power reaches the rated value. Synthetic The modified polyester has a glass transition temperature of 100°C, an intrinsic viscosity of 0.895dL / g, a terminal carboxyl group of 23mol / t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com