Preparation method of environmentally-friendly pyrethrin controlled-release microspheres

A pyrethrin and environment-friendly technology, which is applied in the field of preparation of environment-friendly pyrethrin controlled-release microspheres, can solve the problems that the effective activity of the preparation is affected, the application time is short, and the application cost is increased, so as to prolong the application interval, Good molecular reaction kinetics, prolonging the duration of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

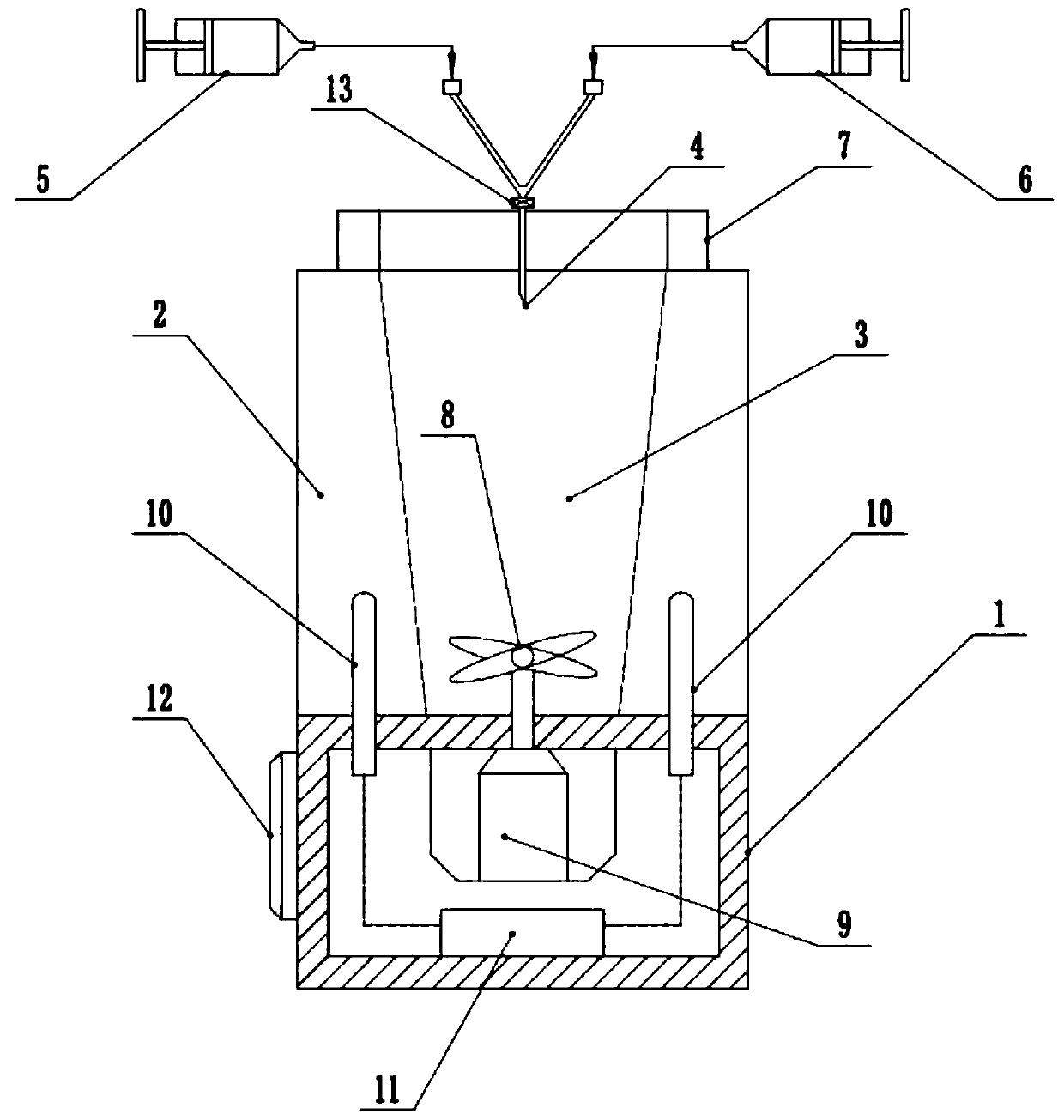

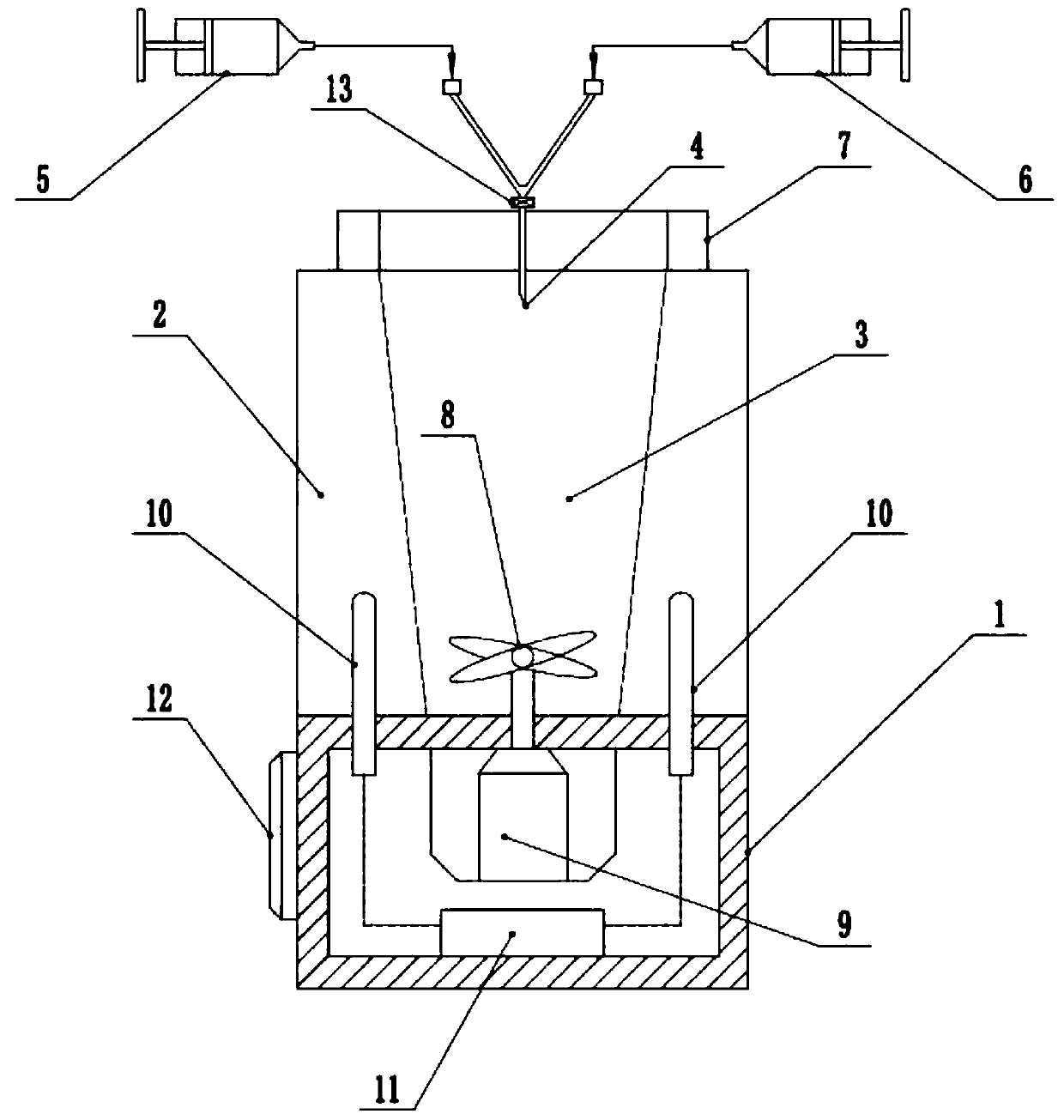

Image

Examples

Embodiment 1

[0033] A preparation method of environment-friendly pyrethrin controlled-release microspheres, comprising the following steps;

[0034] S1: Mix magnetic nanoparticles and alkaline water at a volume ratio of 1:10, use ultrasonic waves to wash for 10 minutes, filter with suction, add ethanol to prepare a magnetic nanoparticle solution with a magnetic nanoparticle concentration of 14%, and divide into Two groups of magnetic nanoparticle solution A and magnetic nanoparticle solution B; advantage. The alkaline water is a sodium carbonate aqueous solution with a pH of 11. The alkaline water is used to oscillate and clean the surface of the magnetic nanoparticles, which has a high degree of cleanliness and can improve the surface properties of the magnetic nanoparticles and increase their loading rate.

[0035] S2: Add 45% pyrethrins by volume to magnetic nanoparticle solution A, disperse evenly by ultrasonic, and then mix with environment-friendly high molecular polymer (polybutyle...

Embodiment 2

[0043] A preparation method of environment-friendly pyrethrin controlled-release microspheres, comprising the following steps;

[0044] S1: Mix magnetic nanoparticles and alkaline water at a volume ratio of 1:22, use ultrasonic waves to wash for 12 minutes, filter with suction, add ethanol to prepare a magnetic nanoparticle solution with a magnetic nanoparticle concentration of 16%, and divide into Two groups of magnetic nanoparticle solution A and magnetic nanoparticle solution B; advantage. The alkaline water is an aqueous solution of sodium carbonate with a pH of 11.5. The alkaline water is used to oscillate and clean the surface of the magnetic nanoparticles, which has a high degree of cleanliness and can improve the surface properties of the magnetic nanoparticles and increase their loading rate.

[0045] S2: Add 48% by volume pyrethrins to the magnetic nanoparticle solution A, disperse evenly by ultrasonic, and then dissolve in oil with environment-friendly high molecul...

Embodiment 3

[0053] A preparation method of environment-friendly pyrethrin controlled-release microspheres, comprising the following steps;

[0054] S1: Mix magnetic nanoparticles and alkaline water at a volume ratio of 1:25, use ultrasonic waves to wash for 15 minutes, filter with suction, add ethanol to prepare a magnetic nanoparticle solution with a magnetic nanoparticle concentration of 18%, and divide into Two groups of magnetic nanoparticle solution A and magnetic nanoparticle solution B; advantage. The alkaline water is an aqueous solution of sodium carbonate with a pH of 12. The alkaline water is used to oscillate and clean the surface of the magnetic nanoparticles, which has a high degree of cleanliness and can improve the surface properties of the magnetic nanoparticles and increase their loading rate.

[0055] S2: Add 50% pyrethrins by volume to the magnetic nanoparticle solution A, disperse evenly by ultrasonic, and then dissolve it in the oil phase (acetic acid) with the envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com