Flexible boron nitride nano-belt aerogel and preparation method therefor

A boron nitride and nanobelt technology, applied in aerogel preparation, gel preparation, chemical instruments and methods, etc., can solve the mechanical strength of boron nitride aerogel weak and brittle, and the thermal stability of boron nitride aerogel. It has the advantages of good resilience, low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Another aspect of the embodiment of the present invention also provides a method for preparing flexible boron nitride nanoribbon airgel, which mainly includes: dissolving boric acid and nitrogen-containing precursor small molecules at high temperature to obtain a transparent precursor solution; Ultrasonic and cooling to obtain precursor hydrogel, followed by specific drying method and high temperature pyrolysis to obtain flexible boron nitride nanoribbon aerogel.

[0055] Specifically, the preparation method of the flexible boron nitride nanoribbon aerogel provided by the invention includes:

[0056] 1) Dissolving boric acid and nitrogen-containing precursors in a solvent at high temperature to obtain a transparent precursor solution;

[0057] 2) cooling the precursor solution to obtain a precursor hydrogel;

[0058] 3) drying the precursor hydrogel to obtain a precursor aerogel;

[0059] 4) In a protective atmosphere, the precursor airgel is subjected to high-tempera...

Embodiment 1

[0073] (a) Add 0.03 mol of boric acid and 0.003 mol of melamine into 100 mL of methanol solution, and stir in a water bath at 65°C until the solution system becomes transparent.

[0074] (b) The transparent solution in step (a) was ultrasonically treated at 0.1 W for 30 min at 5° C. to obtain a white boric acid / melamine hydrogel.

[0075] (c) Place the white boric acid / melamine hydrogel in step (b) in a freeze dryer, and freeze-dry for 24 hours to obtain the boric acid / melamine hydrogel.

[0076] (d) The boric acid / melamine airgel in step (c) was subjected to high-temperature pyrolysis treatment for 12 hours at 600° C. under an argon / ammonia atmosphere to obtain flexible boron nitride nanoribbon airgel.

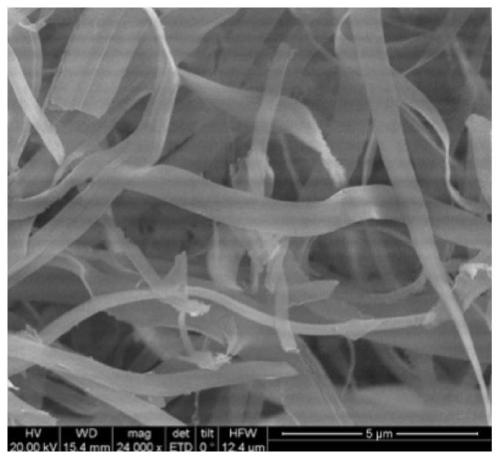

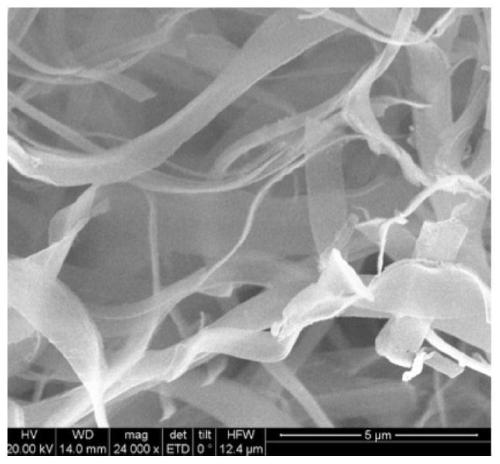

[0077] The structure and performance characterization data of the airgel obtained in this example are as follows: After BET testing, the specific surface area of the boron nitride nanoribbon airgel is 980m 2 / g, the pore size distribution is 0.5-50nm, and its SEM structure...

Embodiment 2

[0079] (a) Add 0.15mol boric acid and 0.45mol melamine to 175mL water / ethanol mixed solution (volume ratio of water and ethanol 10:1), and stir in a water bath environment at 90°C until the solution system becomes transparent.

[0080] (b) The transparent solution in step (a) was ultrasonically treated for 10 h at 55° C. under a power of 10,000 W to obtain a white boric acid / melamine hydrogel.

[0081] (c) Place the white boric acid / melamine hydrogel in the step (b) in an oven at 65° C. and let it dry for 24 hours to obtain the boric acid / melamine hydrogel.

[0082] (d) pyrolyzing the boric acid / melamine airgel in step (c) at 1500° C. under a nitrogen atmosphere for 24 hours to obtain flexible boron nitride nanoribbon airgel.

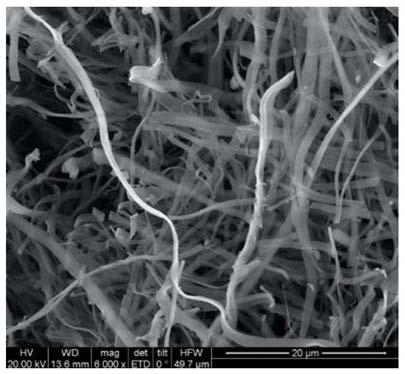

[0083] The scanning electron microscope (SEM) photo of the obtained boron nitride nanoribbon airgel of the present embodiment is as follows figure 2 The relevant physical parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com