Preparation method of organic composite material film and method for improving thermoelectric performance of organic composite material film

A composite material film, thermoelectric performance technology, applied in the field of organic thermoelectric materials, can solve problems such as poor thermoelectric performance, and achieve the effects of low cost, excellent stability, and simple preparation process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

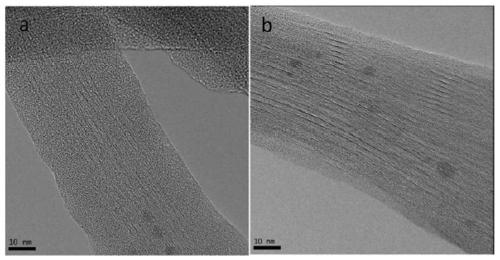

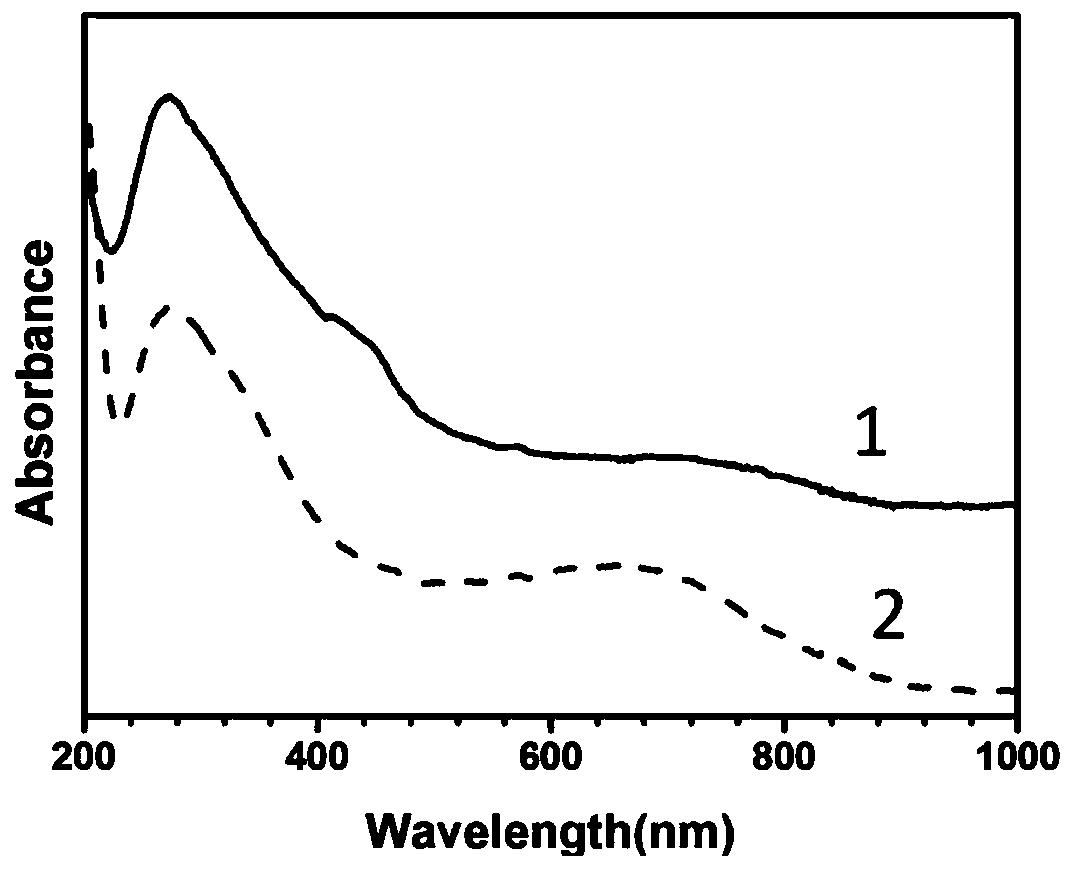

[0023] Example 1: Prepare carbon nanotube (CNT) and polyaniline (PANI) composite powder by in-situ oxidative polymerization, add it to 0.1mol / L ammonia water, stir to remove doping, filter, wash with water and vacuum dry at 60°C After obtaining carbon nanotubes and intrinsic state polyaniline powder, take appropriate amount of carbon nanotubes and intrinsic state polyaniline powder, and add camphorsulfonic acid in a ratio of 2:1 to the molar ratio of polyaniline to camphorsulfonic acid. Doping, dispersing in m-cresol solvent and stirring to obtain a dispersion solution. The dispersion solution was dropped on a glass substrate and dried at 40°C to prepare an organic composite film, in which the carbon nanotube content was 70% by weight, and a part of the organic composite film was subjected to ultraviolet-visible light absorption analysis. The results are as follows figure 2 Line 1,

[0024] The film is immersed in 0.001mol / L ammonia solution at room temperature for 1min, then r...

Embodiment 2

[0025] Example 2: Same as Example 1, except that a camphorsulfonic acid doped organic composite film was prepared. The film was soaked in a 0.01mol / L ammonia solution at room temperature for 1 min, and then rinsed with water three times to neutrality and dried. Finally, its conductivity is reduced to 2405S cm -1 , Seebeck coefficient increased to 33μVK -1 , The power factor is increased to 262μWm -1 K -2 .

Embodiment 3

[0026] Example 3: Same as Example 1, with the difference that an organic composite film doped with camphorsulfonic acid was prepared. The organic composite film was immersed in a 1mol / L ammonia solution at room temperature for 1 min, and rinsed with water three times to Neutral and dry. Finally, its conductivity is reduced to 2068S cm -1 , Seebeck coefficient increased to 41μV K -1 , The power factor is increased to 348μWm - 1 K -2 , See Table 1 for details. At the same time, the organic composite film treated with lye is subjected to ultraviolet-visible light absorption analysis, and the results are as follows figure 2 The line 2 in the figure shows that the light absorption of the blend film prepared by the present invention is more obvious at 750 nanometers (the local π-polaron transition between PANI molecular chains), and the blue shift is also 440. The absorption peak at the nanometer (PANI molecular chain polaron-π * (Transition) The strength becomes weaker and almost ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com