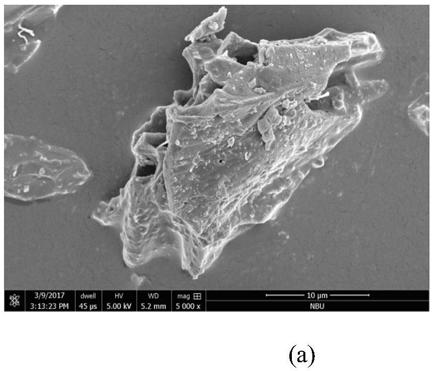

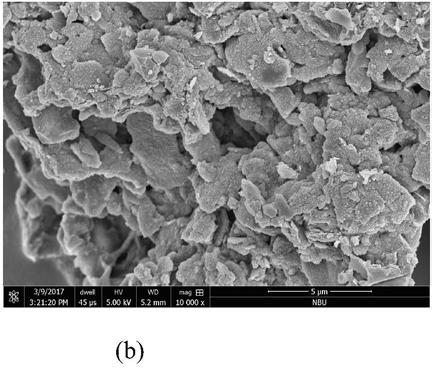

Method for preparing polylactic acid/bamboo particle/bamboo charcoal composite materials

A composite material, polylactic acid technology, applied in the field of preparation of polylactic acid/bamboo particles/bamboo charcoal composite materials, can solve the problem of incomplete optimization of ultra-fine bamboo charcoal pore channels, limited improvement in toughness and other properties, and increased tensile elongation at break, etc. problems, to achieve the effect of increasing the specific surface area and surface activity, improving the performance of the surface and interface, and improving the aggregation form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation method of the polylactic acid / bamboo particle / bamboo charcoal composite material of embodiment 1, comprises the following steps:

[0046] 1), first carry out broomification pretreatment to the bamboo particles, the specific process is:

[0047] Take bamboo granules with a particle size of 40 meshes and pre-dry them at 100°C for 15 hours to obtain dried bamboo granules;

[0048] Prepare pretreatment liquid, this pretreatment liquid is formulated with the weight ratio of 5:12:83 by NaOH, urea and pure water;

[0049] Take an appropriate amount of dry bamboo granules and put them into the pretreatment solution, soak them at room temperature for 4 hours, then use a centrifuge to repeatedly add pure water to centrifuge 5 times at a speed of 9000rpm, and then use a sand core funnel to repeatedly filter and wash 4 times to remove residual NaOH and urea to get swelling bamboo particles;

[0050] Take an appropriate amount of swollen bamboo particles and put th...

Embodiment 7

[0067] The preparation method of the polylactic acid / bamboo particle / bamboo charcoal composite material of embodiment 7, the difference with embodiment 1 is, in the step 1) of embodiment 7, pretreatment liquid is by NaOH, urea and pure water with 7:13:80 The weight ratio is formulated, and the homogenization treatment conditions are: homogenization treatment at 60°C and 120MPa for 60 minutes, the silane coupling agent is A-151, and methanol / water solution is changed to ethanol / water solution; step 2) The silane coupling agent is A-151, and the HNO with a material-to-liquid ratio of 55g / 100mL is prepared 3 / aqueous solution, methanol / aqueous solution is changed into ethanol / aqueous solution; The nucleating agent used in step 3) is the PEG of molecular weight 2000, and consumption is 4% of polylactic acid particle weight; Step 4) in, change thermocompression molding into extrusion The process of extrusion molding and extrusion molding is as follows: send the mixed sample into th...

Embodiment 13

[0070] The preparation method of the polylactic acid / bamboo particle / bamboo charcoal composite material of embodiment 13, the difference with embodiment 1 is, in the step 1) of embodiment 7, pretreatment liquid is made of NaOH, urea and pure water with 6:13:81 The weight ratio is formulated, the homogenization treatment conditions are: homogenization treatment at 70°C and 110MPa for 50min, the silane coupling agent is KH-550, the methanol / water solution is changed to ethanol / water solution, and the ratio of 1g / Add silane coupling agent KH-550 as a surface modifier to the ethanol / water solution at a solid-liquid ratio of 20mL, and the stirring hydrolysis time at 50°C is 40min; in step 2), the prepared solid-liquid ratio is 55g / 100 mL of HNO 3 / water solution, the silane coupling agent is KH-550, change the methanol / water solution to ethanol / water solution, add the silane coupling agent KH-550 as a surface modifier to the ethanol / water solution at a solid-liquid ratio of 1g / 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com